Ratchet wheel type thread initial point resetting device

A technology of reset device and starting point, which is applied in the field of ratchet thread starting point reset device, can solve the problems of heavy workload, heavy maintenance, waste oil cylinders, etc., and achieve the effects of reducing workload, reliable work and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

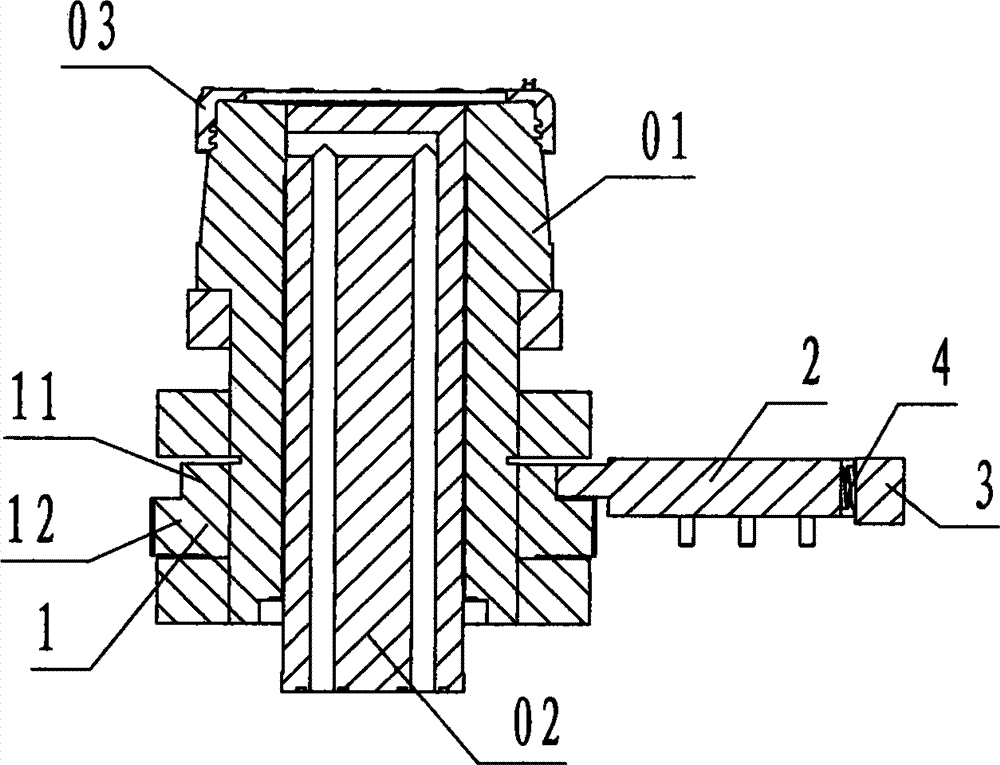

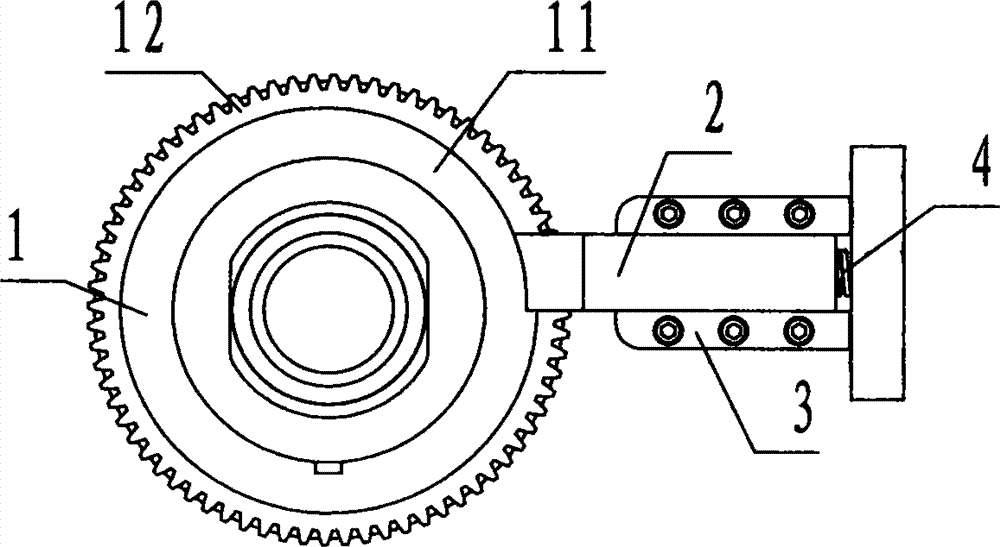

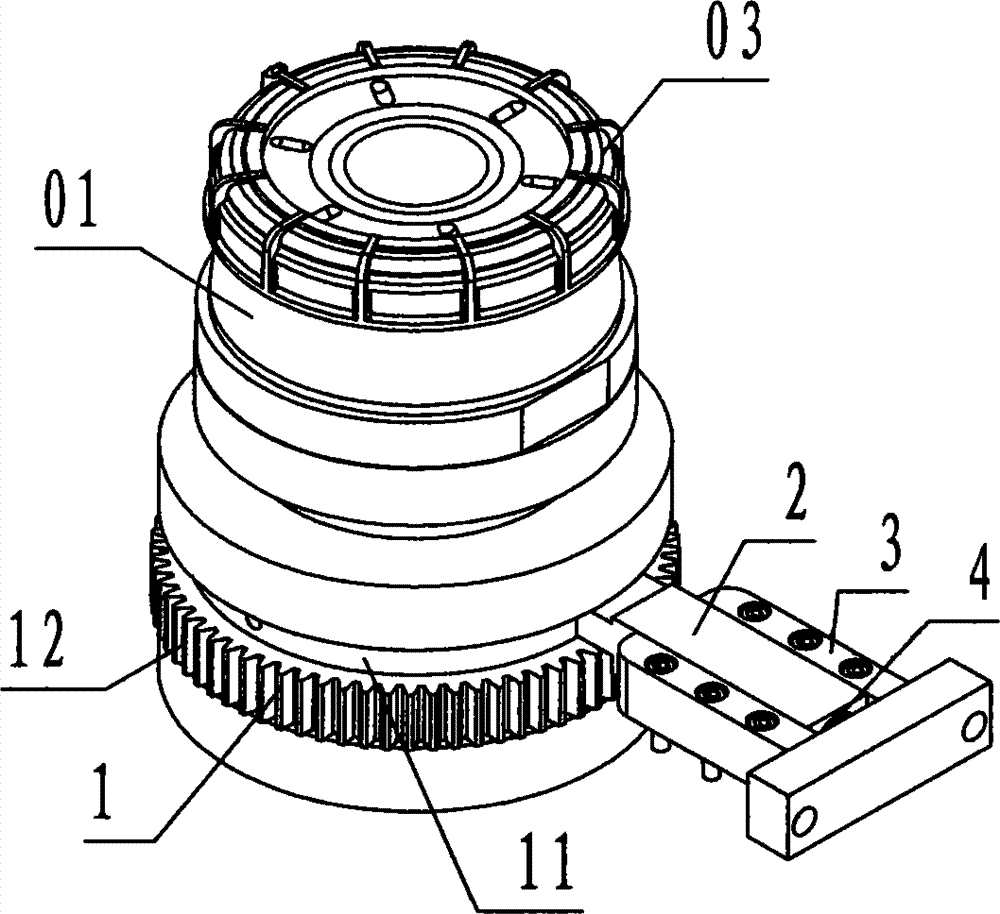

[0022] refer to Figure 1 ~ Figure 3 , a ratchet-type thread starting point reset device of the present invention includes a ratchet double wheel 1, a pawl 2, a chute 3, and a spring 4, wherein: the ratchet double wheel 1 is a small upper and a lower large cylinder Step-shaped steel member, the center of the ratchet double wheel 1 is provided with a circular through hole in the up and down direction called the shaft hole, and the outer edge of the upper small step of the ratchet double wheel 1 is a single stop that rotates counterclockwise. The ratchet wheel 11 of tooth, the outer edge of the bottom big step of ratchet duplex wheel 1 is the gear 12 of cylindrical spur tooth;

[0023] The ratchet 2 is a rectangular block-shaped steel member, the left part of the ratchet 2 is called the claw head, the left end surface of the claw head is an arc-shaped arc surface, and the front and rear sides of the right part of the ratchet 2 are The flanges with protruding, rectangular cross-...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap