Photocuring 3D printing technology-based metal insert resin part rapid manufacturing method

A metal insert, 3D printing technology, applied in the field of 3D printing, can solve the problem of inapplicable metal insert resin parts, etc., to shorten the parts manufacturing cycle, improve product development efficiency, and reduce manual errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0038] Example.

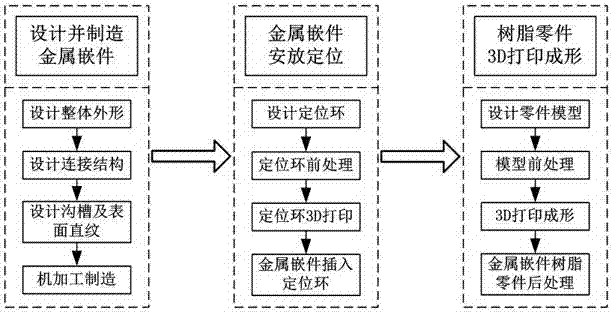

[0039] see Figure 1-Figure 8 , a rapid manufacturing method of metal insert resin parts based on light-curing 3D printing technology, including the following steps: (1) Design and manufacture metal insert 1

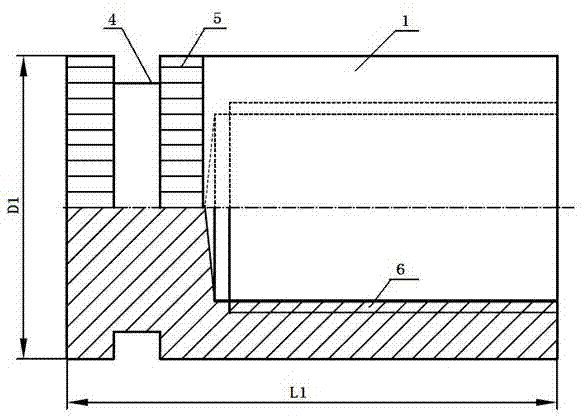

[0040] see figure 2 According to the actual shape and size of the transmission shaft and impeller 3, design a cylindrical metal insert 1 of appropriate size. It is generally required that the outer diameter D1 of the metal insert should be at least 10mm larger than the diameter of the transmission shaft to ensure the connection between the metal insert 1 and the transmission shaft. The connection strength meets the requirements of working strength, and it is generally required that the len...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com