Large crane lifting monitoring control system

A monitoring control and crane technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of reduced production efficiency, collision of loading and unloading machinery and cargo, and potential safety hazards, so as to improve work efficiency, ensure operation quality, and eliminate safety hazards. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

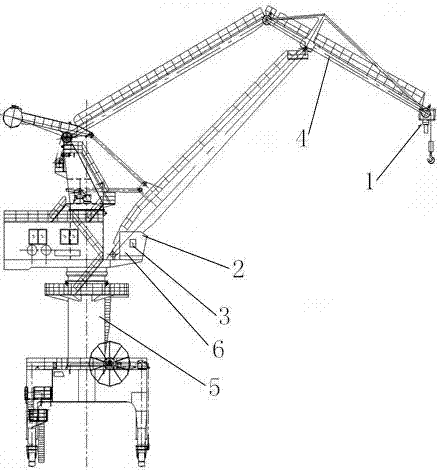

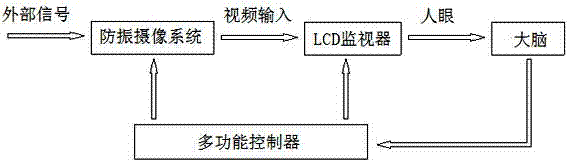

[0024] see Figure 1-2 , the specific installation and connection methods in the figure are, the crane 5 is provided with a control room 6 and a boom 4, the side of the control room 6 is equipped with a multi-channel multi-function controller 2 and a monitor 3, the head of the boom 4 is vertical An anti-vibration camera system 1 is installed directly.

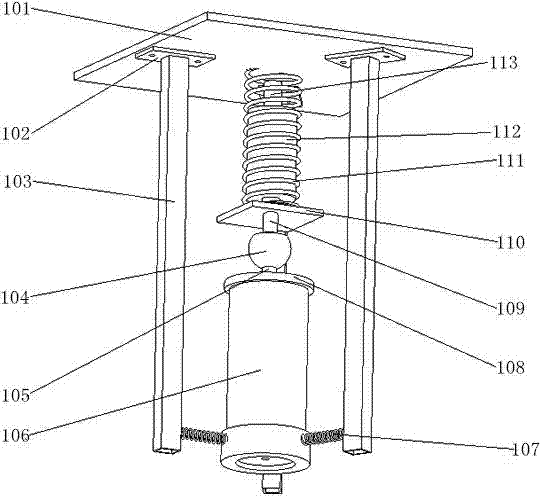

[0025] figure 2 Among them, the bottom surface of the mounting plate 101 is provided with an axial damper, the damping shaft 113 of the damper is installed vertically, its upper end is connected to the mounting plate 101, and the lower end is arranged in the damping shell 112 of the damper, and the damping shaft 113 of the damping shell 112 The lower end is connected to the baffle plate 110, the lower surface of the baffle plate 110 is provided with a ball hinge 104, the upper end shaft 109 of the ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com