Installation and construction method for large-diameter pipe bridge on ultra-wide river way

A large-diameter pipe and construction method technology, applied in bridges, bridge applications, bridge construction and other directions, can solve the problems that crane hoisting cannot meet construction, cannot set up temporary supports, cannot carry out interception construction, etc., to simplify water operations and reduce construction costs. Risky, high-stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Embodiment: The super-wide channel large-diameter pipe bridge installation and construction method of this example is characterized in that the described method includes:

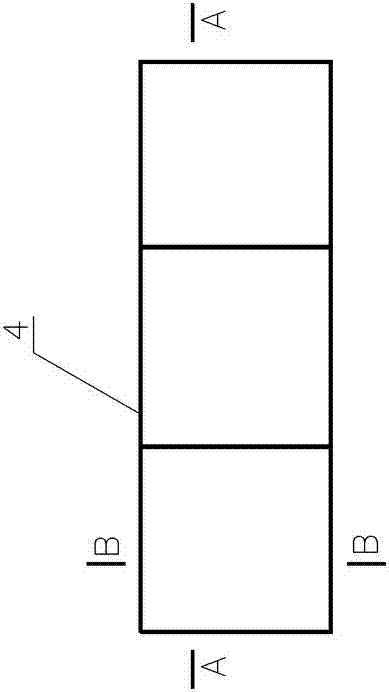

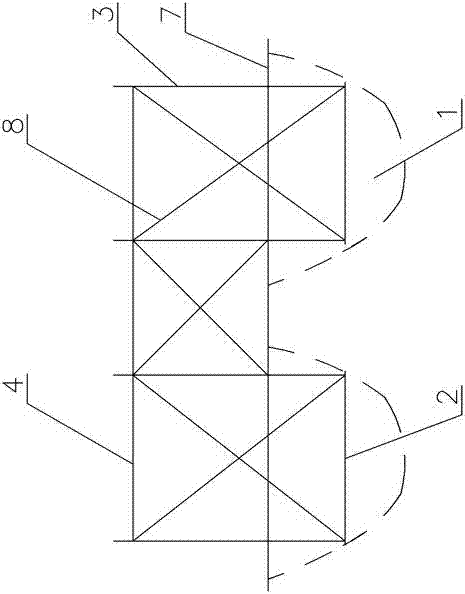

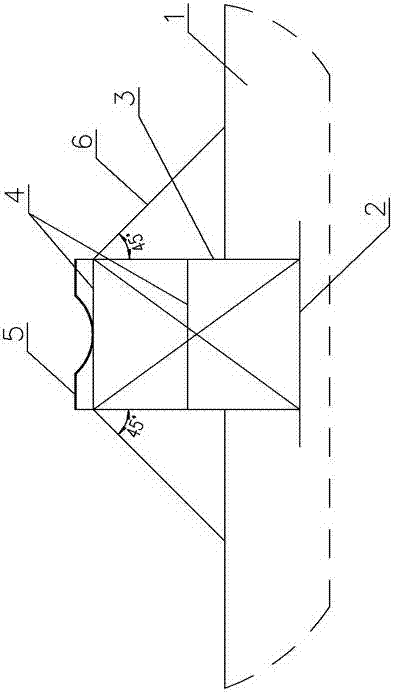

[0033] a. Construction preparation: Level the site, arrange material sheds and equipment installation locations reasonably, and form a construction access road to the shore; the lower structure of the pipe bridge has passed the acceptance inspection and meets the pipeline installation conditions; the elevation, center line and The span of the hole, after inspection, meets the design and pipeline installation requirements, the support structure and embedded parts connected to the pipeline support base have been aligned and accepted; the carrying capacity of the floating platform and the hoisting capacity of the crane are calculated; at the same time, according to Design, manufacture and install the ship’s steel support for the maximum load capacity. The ship’s steel support includes a cabin 1, and more...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap