Adjustable jet pump

A jet pump, adjustable technology, applied in the direction of jet pump, non-displacement pump, pump, etc., can solve the problem of time-consuming, achieve the effect of avoiding pressure loss, simplifying work process and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

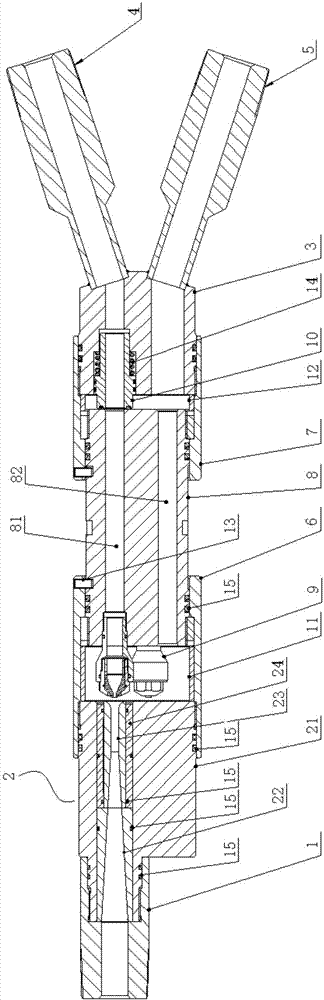

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0016] like figure 1 As shown, the present invention includes an upper joint 1, a jet pump body 2, a lower joint 3, a power fluid connection joint 4 and a low-pressure fluid connection joint 5. Wherein, the upper joint 1 communicates with the outlet section of the jet pump body 2, and the power fluid connection joint 4 and the low pressure fluid connection joint 5 are respectively connected with the power fluid flow channel and the low pressure liquid flow channel of the lower joint 3. The innovation of the present invention is that it also includes a bridge channel 8 that is movably connected between the jet pump pump body 2 and the lower joint 3 through the upper connecting sleeve 6 and the lower connecting sleeve 7, and the bridge channel 8 can surround its center The axis rotates 360°. Three high-pressure flow channels 81 and one low-pressure fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com