Dynamic performance test platform of vibration isolator system and test method thereof

A technology of system dynamics and test platform, which is applied in vibration test, machine/structural component test, mechanical component test, etc., can solve the problem of unstandardized and standardized test platform for vibration exciter scanning method, and does not give excitation scan Problems such as the structure of the law test platform, to achieve the effect of improving the standardization and standardization of the test, and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

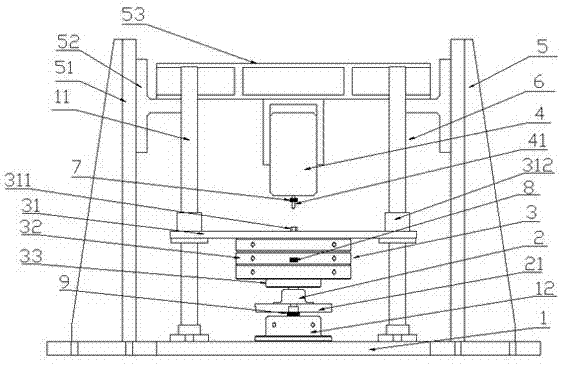

[0029] Such as figure 1 As shown, the test platform for testing the dynamic performance of the vibration isolator system includes a base platform 1, a vibration isolator 2, a mass component 3 and a vibration exciter 4, and the vibration isolator 2 is placed at the center of the base platform 1. The described The mass assembly 3 is placed on the top of the vibration isolator 2 and is detachably connected to the vibration isolator 2. The base platform 1 is equipped with a vibration exciter mounting bracket 5, and the vibration exciter mounting bracket 5. Suspend and install the vibrator 4 directly above the mass assembly 3. A vibration input rod 41 is provided at the center of the bottom of the vibrator 4. Connect the vibration input rod 41 to the The mass component 3 is detachably connected to transmit the vibration of the exciter 4 to the mass com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com