Drainage device of converter gas analyzer

A technology of drainage device and converter gas, which is applied in the preparation of test samples, etc., can solve problems affecting work continuity and work efficiency, analyzer damage, explosion danger, etc., to avoid failure and damage to sampling pumps, and reduce humidity alarms. efficiency, reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and an embodiment.

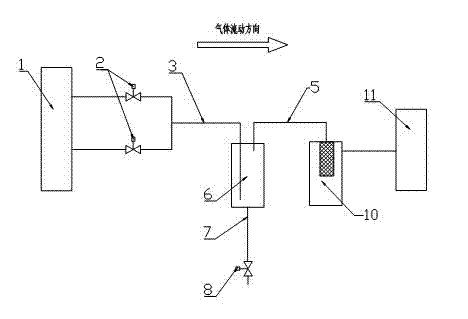

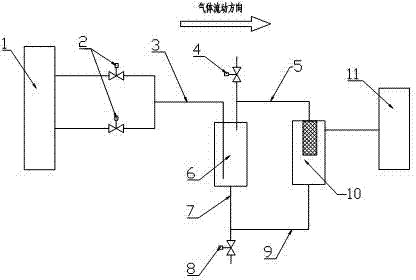

[0020] like figure 2 As shown, the present invention includes a steam-water separator 6 and a sample gas filter 10, the gas inlet of the steam-water separator 6 communicates with the sample gas inlet pipeline 3 equipped with a valve 2, and the water outlet at the lower end of the steam-water separator 6 is connected to a There is a separator drainage pipeline 7 with a drainage valve 8, and the gas outlet of the steam-water separator 6 communicates with the inlet of the sample gas filter 10 through the ventilation pipeline 5, and the ventilation pipeline 5 is provided with a ventilation valve 4 communicating with the atmosphere ; The bottom of the sample gas filter 10 communicates with the water inlet end of the drain valve 8 on the separator drain line 7 through the filter drain line 9 .

[0021] The overall drainage principle and process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com