Preparation method of copper zinc tin selenium thin film solar cell

A technology of copper-zinc-tin-selenium thin film and solar cells, which can be applied to circuits, photovoltaic power generation, electrical components, etc., can solve problems such as complex processes, and achieve the effects of simple process flow, high safety, and improved electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

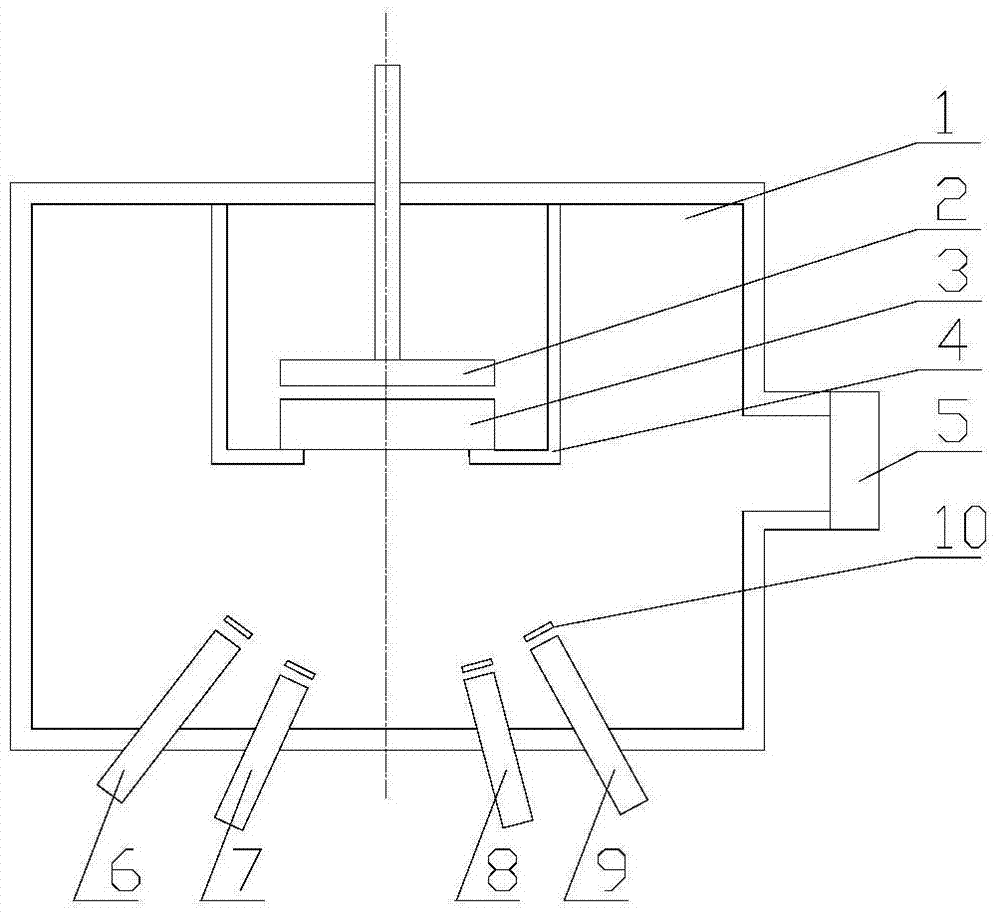

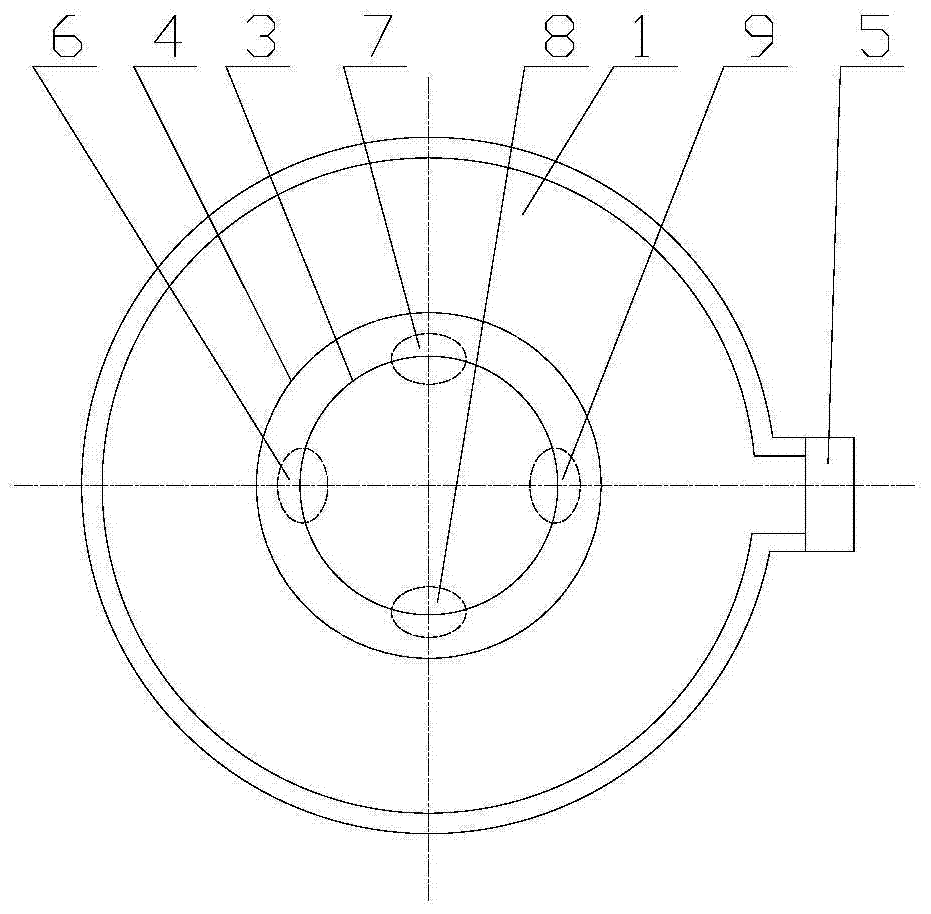

[0030] The preparation method of copper-zinc-tin-selenium thin-film solar cell is characterized in that it comprises the following steps:

[0031] Step 1. Put the side with the Mo back electrode on the substrate downward into the rotatable sample holder in the evaporation chamber, and place the substrate heater above the substrate; Cu, Zn, Sn, Se as evaporation sources Uniformly distributed around the bottom of the Mo back electrode of the substrate in the evaporation chamber, and an evaporation source baffle is placed on each evaporation source;

[0032] Step 2. Use a vacuum pump to evacuate the evaporation chamber to 10 -4 Pa, heat the substrate to 380°C, heat Cu in each evaporation source to 1100°C-1200°C, Zn to 280°C-380°C, Sn to 1000°C-1100°C, Se to 200°C-250°C , rotate the sample holder, open the evaporation source baffle above Zn, Sn, Se, co-evaporate Zn, Sn, Se on the Mo back electrode of the substrate, the evaporation time is 10min, deposit a layer of preset layer fi...

Embodiment 1

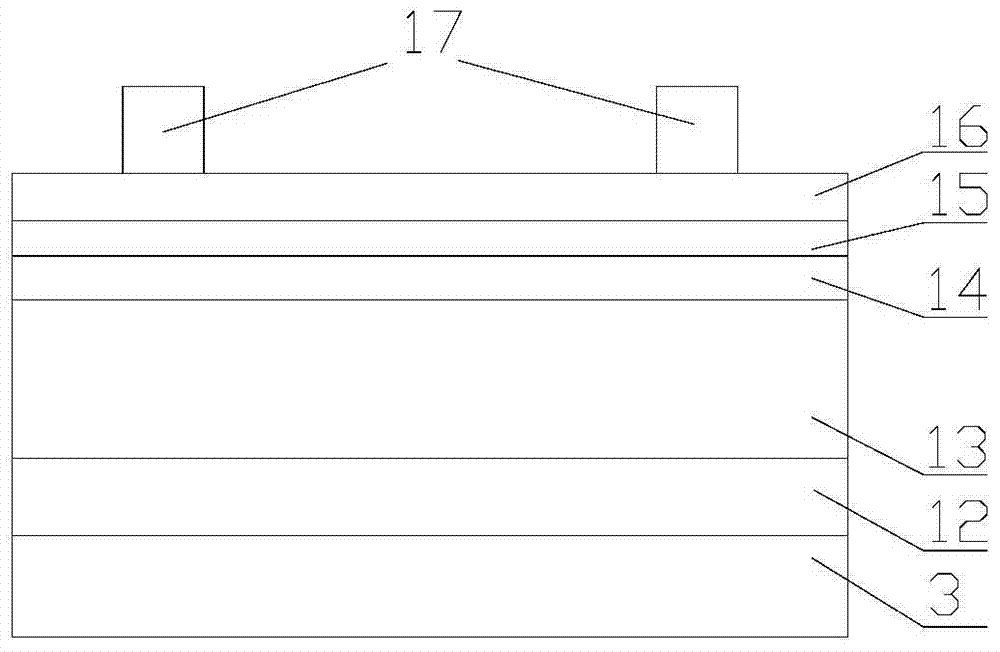

[0043] Adopt soda-lime glass as the substrate 3, deposit a 1 μm thick Mo back electrode 12 on the substrate by magnetron sputtering; prepare a copper-zinc-tin-selenium absorbing layer on the Mo back electrode; the copper-zinc-tin-selenium absorbing layer The preparation process is as follows: (1) Place the side of the substrate with the Mo back electrode down into such as figure 1 with figure 2 In the rotatable sample holder 4 of the evaporation chamber 1 shown; above the substrate is placed a substrate heater 2 composed of electric furnace wire coiled on a stainless steel tray; as the evaporation source, Cu, Zn, Sn, Se are evenly distributed In the periphery below the Mo back electrode in the evaporation chamber, each evaporation source is equipped with a thermocouple for monitoring the evaporation temperature, and each evaporation source is equipped with an evaporation source baffle 10; Vacuum to 10 -4 Pa, heat the substrate to 380°C; controlled by a thermocouple, heat th...

Embodiment 2

[0045] A stainless steel foil with a thickness of 40 μm was used as the substrate, and other conditions were the same as in Example 1 to prepare a copper-zinc-tin-selenium thin-film solar cell with a stainless steel substrate structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com