Application of catalyst in fuel cell SO2 poisoning resistance, and poisoning recovery method

A technology of fuel cells and fuel cell stacks, applied to battery electrodes, circuits, electrical components, etc., can solve problems such as inability to oxidize, and reducing atmosphere hinders SO2 oxidation and removal, and achieve the effect of performance recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

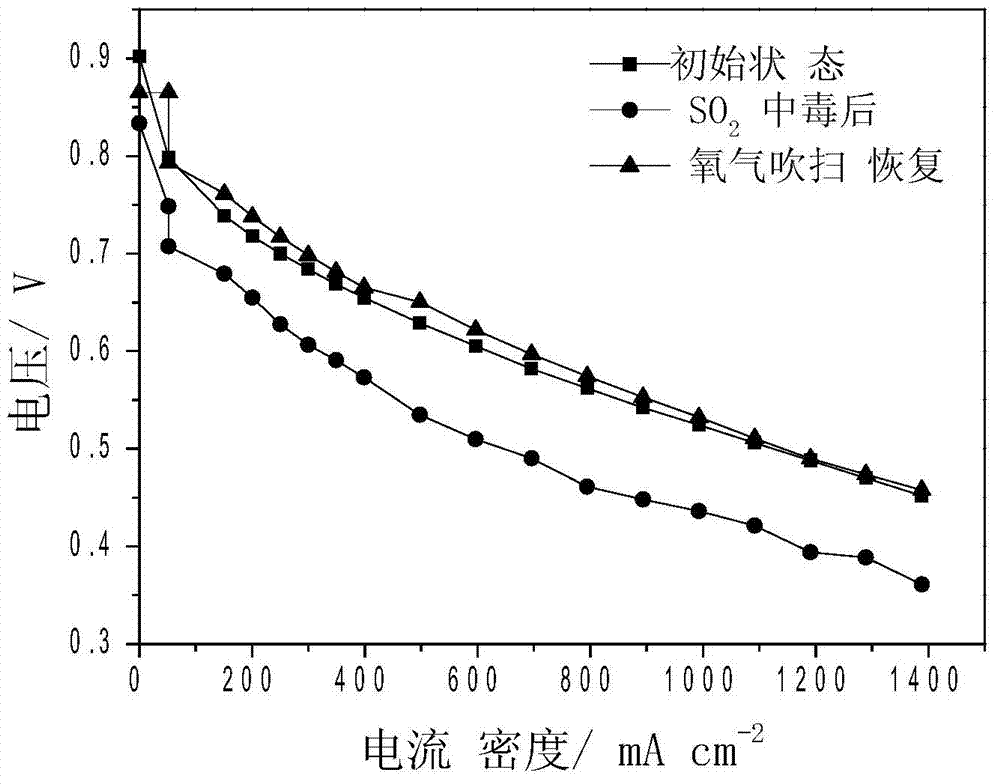

Embodiment 1

[0023] A single cell is assembled according to a method well known in the fuel cell field, wherein the active component of the cathode catalyst of the single cell is PtRu, and the Pt loading is 0.4 mg cm -2 . After the battery is activated by methods well known in the art, SO 2 Poisoning and performance recovery experiments after poisoning to evaluate the excellent SO resistance of PtRu catalysts 2 Poisoning performance, specifically reflected in the fact that its performance can be quickly and completely restored when it is purged with air; at the same time, the performance recovery method after poisoning is evaluated, specifically, the anode is fed with nitrogen or air or oxygen, and the cathode is fed with air or oxygen. The utility model has the characteristics of being convenient and easy to operate, and being applicable to electric piles. The specific activation and poisoning process is as follows:

[0024] The battery temperature is 60°C, the cathode and anode humidi...

Embodiment 2

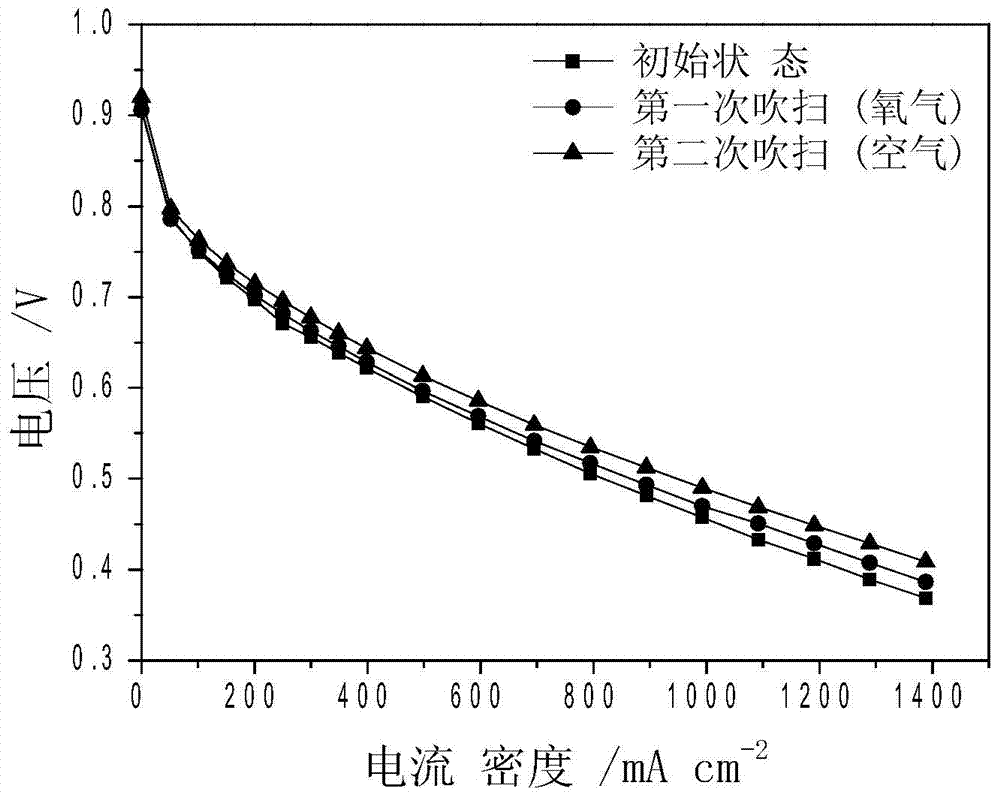

[0027] On the basis of Example 1, in order to further illustrate the effectiveness of the poisoning recovery method described in this patent, repeat the poisoning and recovery method for the battery after the poisoning recovery for the first time, and perform the second poisoning and performance recovery operation , at this time, the cathode purge gas is changed to air, and the anode gas remains unchanged, and the polarization curve after performance recovery is measured, and the polarization curves in each case are obtained, see figure 2 . Depend on figure 2 It can be seen that after the second poisoning recovery, the battery performance is better than both the initial and the first poisoning recovery, which again shows the excellent resistance of PtRu to SO 2 Poisoning performance and excellent effect of the performance recovery method described in this patent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com