A Tool Wear Monitoring Method Based on Current and Acoustic Emission Composite Signal

An acoustic emission signal and tool wear technology is applied in the field of tool wear monitoring based on current and acoustic emission composite signals, which can solve the problem that the stability and reliability of acoustic emission signal monitoring are not too high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further elaborated below in combination with specific embodiments.

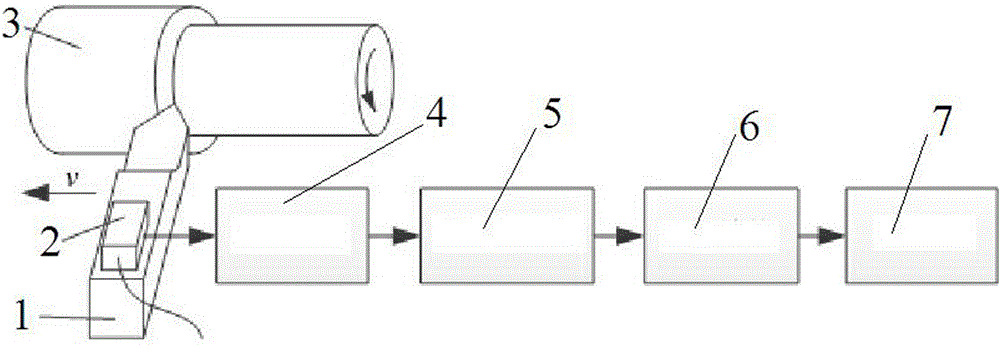

[0062] The detection principle of the acoustic emission (Acoustic Emission, AE) signal that reflects the wear state of the turning tool proposed by the present invention is as follows: figure 1 As shown: the acoustic emission sensor 2 is directly installed on the handle of the turning tool 1 to reduce the large attenuation of the acoustic emission signal when it propagates between the joint surfaces. The acoustic emission signal generated by the turning tool 1 during the cutting process passes through the signal successively Amplifier 4, anti-aliasing filter 5 and A / D converter I6 are stored in computer 7 for subsequent processing and analysis;

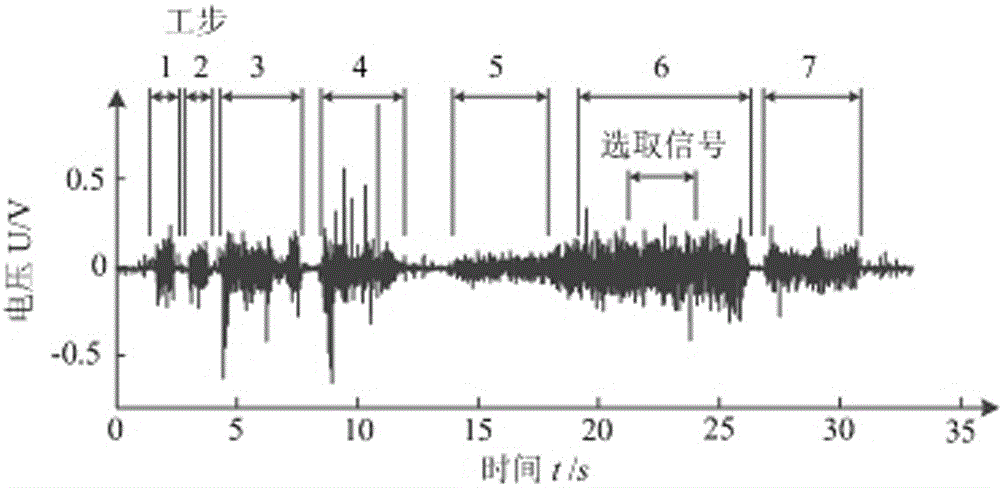

[0063] The described acoustic emission signal processing and analysis process is as follows:

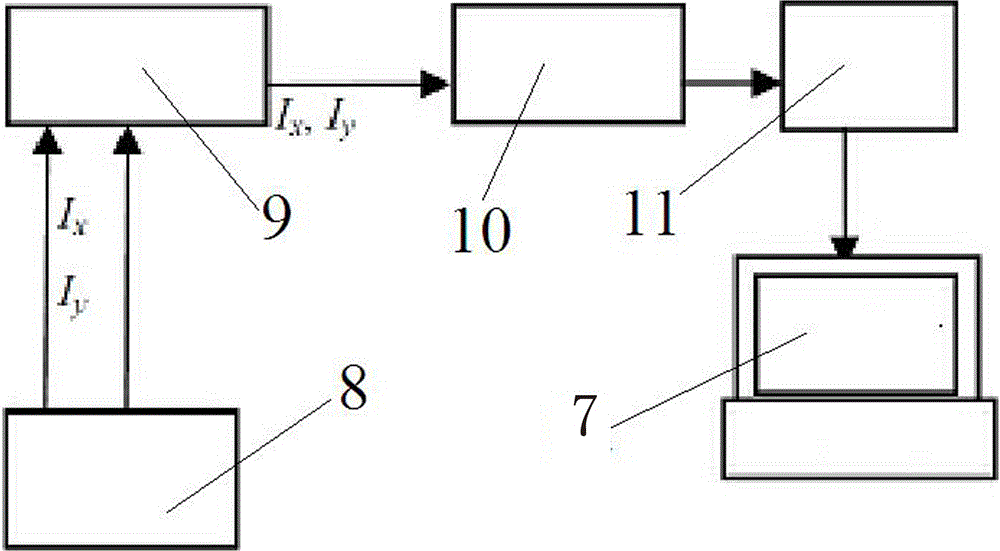

[0064] The principle of tool wear state discrimination is as follows: figure 2 Indicates: under the same processing parameters, set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com