Nut machining method

A processing method and nut technology, applied in metal processing equipment, manufacturing tools, grinding devices, etc., can solve problems such as insufficient rigidity, inability to maintain the forming grinding wheel 11, and decrease in grinding accuracy, and achieve high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method for processing a nut according to a preferred embodiment of the present invention will be described below with reference to the relevant drawings, wherein the same elements will be described with the same reference symbols.

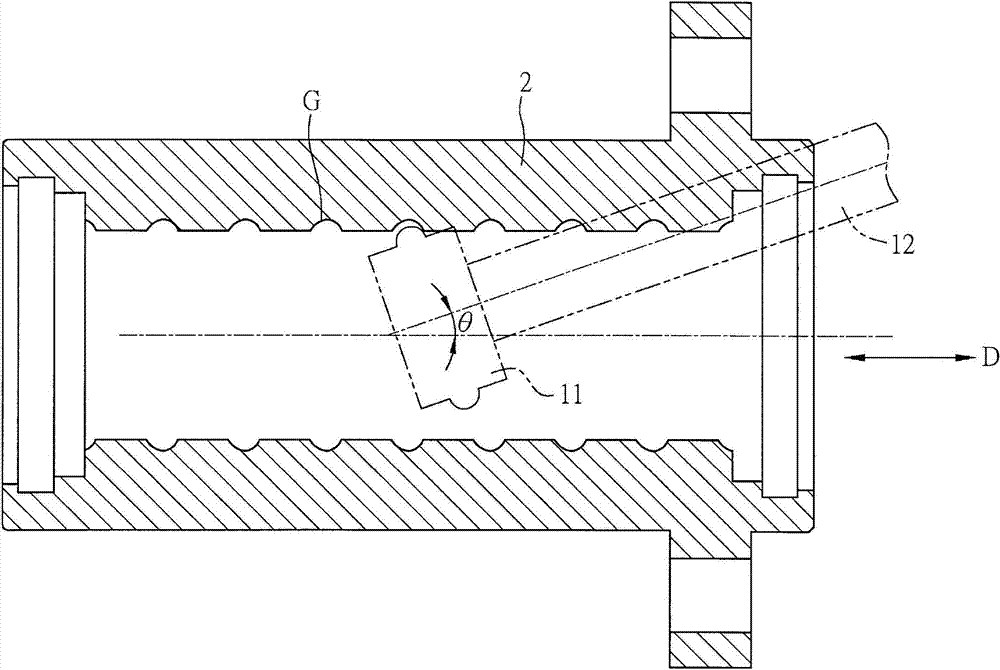

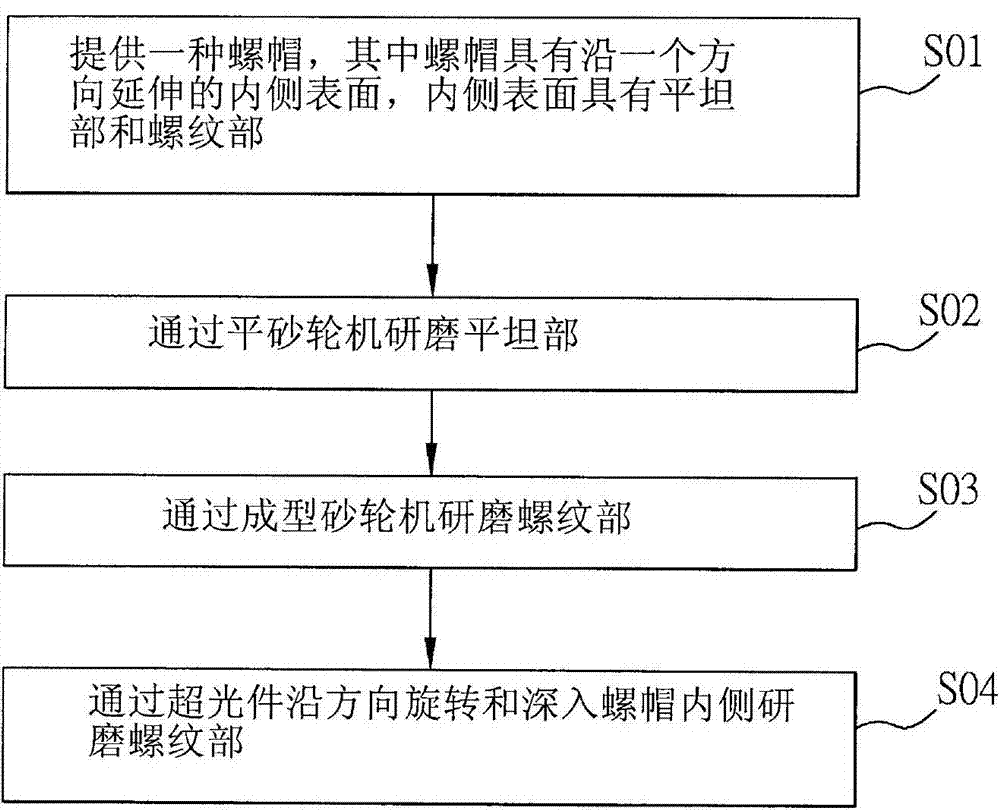

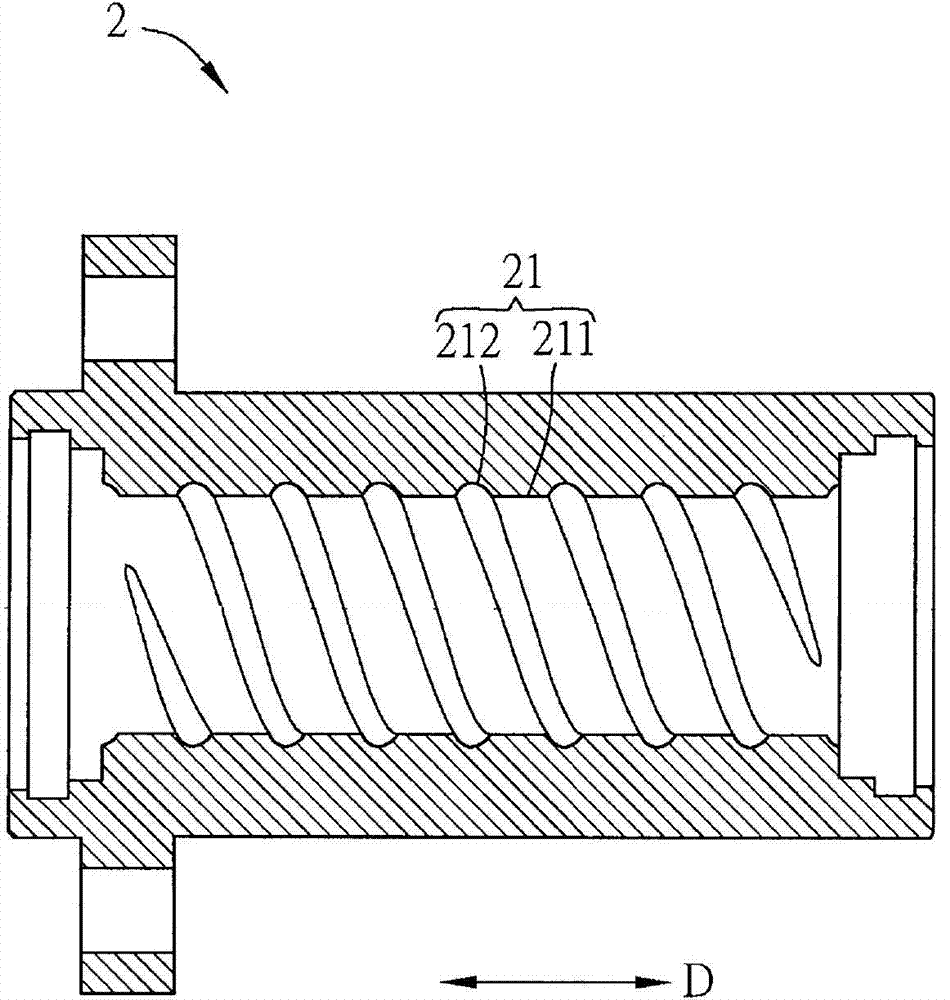

[0024] Please refer to figure 2 , Figure 3A to Figure 3D As shown, among them, figure 2 It is a schematic flow chart of a processing method for a nut in a preferred embodiment of the present invention, and Figure 3A is a schematic cross-sectional view of a nut 2, Figure 3B and Figure 3C Respectively is a schematic diagram of the processing process of a nut 2 of the preferred embodiment of the present invention, and Figure 3D for Figure 3C An enlarged schematic view of region A of .

[0025] The nut processing method of the present invention can be applied to nuts with a helix angle between 1 degree and 50 degrees. As shown in the figure, the processing method of the nut can be applied to grinding the nut 2 to make its prec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com