Conical electric planer capable of planing extra-long carrot filaments

A cone-shaped and carrot technology, applied in the field of kitchen utensils, can solve problems such as low efficacy, and achieve the effects of simple structure, easy cleaning and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

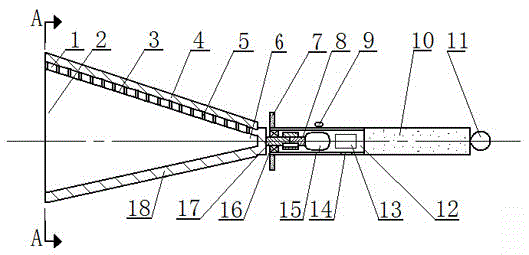

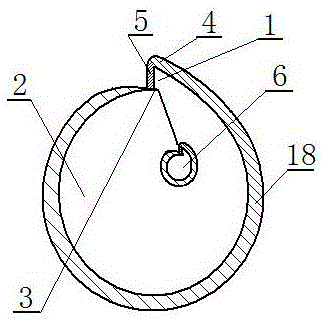

[0018] Example: such as figure 1 , figure 2 As shown, the conical electric planer that can plan extra-long carrot filaments including cutter body 18, knife handle 10 and hanging lug 11, after cutter body 18 is curled into a conical hollow structure by a steel sheet, the inner conical hollow structure The end is set as a blade 3, and the outer end portion 4 of the conical hollow structure covers the top of the blade 3, so that the blade 3 will not expose the end face of the outer end portion 4.

[0019] Evenly distributed small blades 5 are arranged radially between the inner side of the outer end portion 4 and the cutting edge 3 .

[0020] The small blades 5 are provided with a silk outlet slit 1 between them, and the silk outlet slit 1 communicates with the conical hollow structure.

[0021] The blade 3 and the outer end 4 extend from the feed opening 2 to the small end 6 of the cutter body 18 .

[0022] The end of the small head tail end 6 is axially provided with a rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com