Full width windscreen wiper of automobile front window

A wiper, full-width technology, applied in vehicle maintenance, vehicle cleaning, transportation and packaging, etc., can solve the problems of reducing the effect of wipers, achieve reasonable structure, avoid returning to the windshield, and facilitate rainwater separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

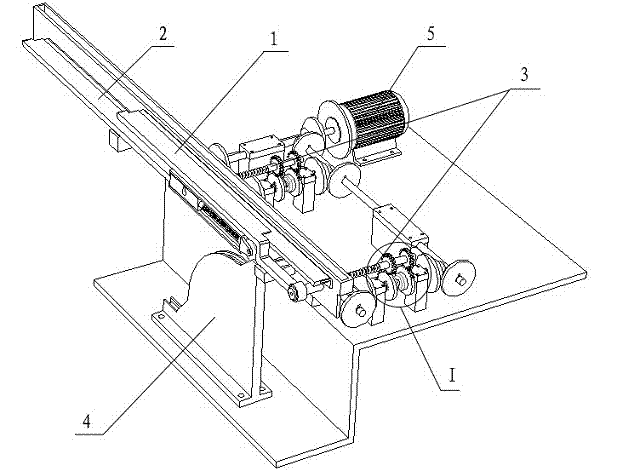

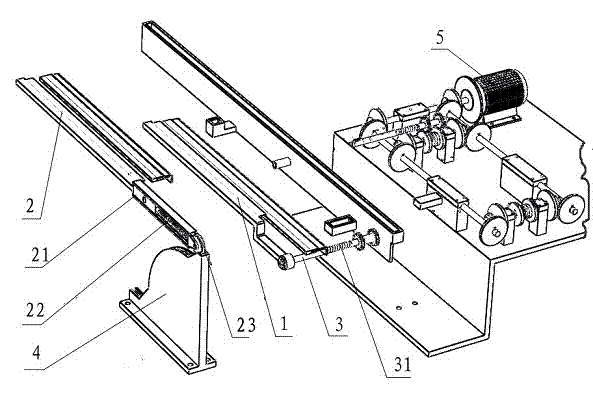

[0030] like figure 1 , 2 As shown, a full-width wiper for the front window of an automobile comprises an upper wiper 1, a lower wiper 2, a rotating shaft 3 and a drive motor 5, and the drive motor 5 drives the upper wiper 1 and the lower wiper 2 through the rotating shaft 3 for cleaning operation, and the lower wiper 2 The wiper arm is provided with a radial channel, and a slider 21 is arranged in the channel. The slider 21 and the bottom end of the radial channel are connected by a telescopic spring 22. The rotating shaft 3 and the slider 21 are fixedly connected by a keyway structure. The lower wiper 2 The bottom end of the bottom is pressed on the track of slideway plate 4 by roller 23, and the section of track is " concave " shape structure.

[0031] The beneficial effect of this embodiment is that: the lower wiper has the characteristics of elastic expansion and contraction, the track of the slideway plate can be customized according to the shape of the windshield, and c...

Embodiment 2

[0033] On the basis of Embodiment 1, a hard spring 31 is provided at the middle position of the rotating shaft 3 .

[0034] The beneficial effect of this embodiment is that: the hard spring can provide a certain amount of cushioning to avoid head-to-head collisions between mechanism parts when failure occurs.

Embodiment 3

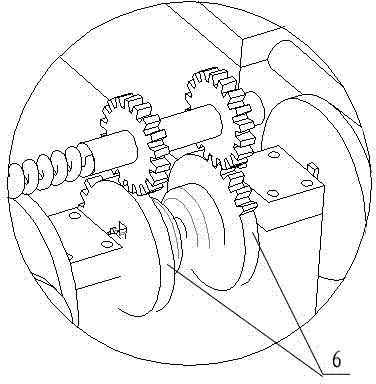

[0036] like image 3 As shown, on the basis of Embodiment 1, the drive motor 5 and the rotating shaft 3 are meshed through a pair of incomplete gears 6. During operation, a pair of incomplete gears 6 are responsible for the pause and drive of the two stages of rising and falling respectively. .

[0037] The beneficial effect of this embodiment is that: the incomplete gear provides a short stay of the wiper during operation, which facilitates the separation of rainwater on the wiper and avoids returning to the windshield to cause secondary pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com