Resin composition and prepreg and laminate using the same

A technology of resin composition and mixture, applied in the field of prepreg, laminate and printed circuit board, resin composition, can solve the problems of low water absorption, high high temperature retention rate of elastic modulus, large expansion coefficient, etc. Good heat and humidity resistance, improved humidity and heat resistance, and high temperature retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] (2) Preparation of resin composition

[0060] Add benzoxazine resin, optional epoxy resin, optional toughening agent, optional curing agent, optional curing accelerator and solvent into a beaker of appropriate capacity in sequence, and stir at high speed to dissolve for 30-60 After dissolving, add amine-modified BMI, optional flame retardant and optional filler, stir for 2 hours to mature, and the solid content and solution viscosity of the resin composition are adjusted by the amount of solvent.

[0061] (3) Production of prepreg

[0062] The prepreg is made by heating and drying the above-mentioned resin composition, and it uses non-woven fabric or other fabrics as the base material, such as natural fibers, organic synthetic fibers and inorganic fibers. Use the above-mentioned resin composition, pre-impregnated fabrics such as glass cloth or organic fabrics, and finally pass the glass cloth through the nip shaft of rolling to remove part of the liquid resin, control ...

Embodiment 1

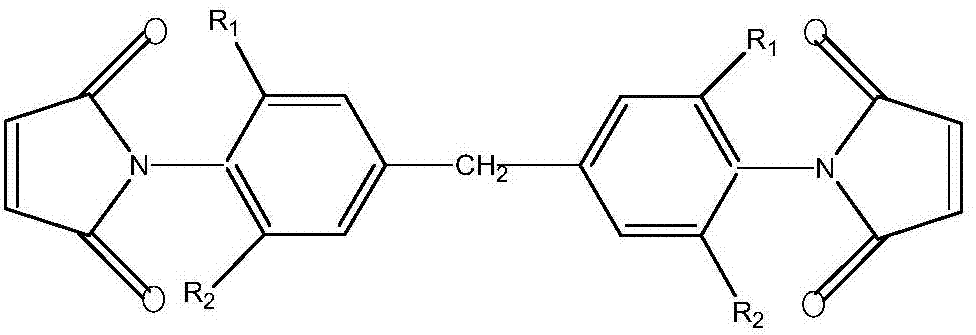

[0066] (1) Preparation of amine-modified BMI

[0067] Diaminodiphenylmethane (DDM) to 3,3'-dimethyl-5,5'-diethyl-4,4'-diphenylmethane bismaleimide (BMI) B239 by weight Feed at 1:10 (molar ratio is about 1:4.5), add it into a three-necked flask, then add an appropriate amount of dimethylacetamide (DMAc) solvent to stir and disperse, blow nitrogen, gradually increase the temperature while stirring to further dissolve, and put The temperature is kept at 100-115 degrees, refluxed for 2-4 hours, and then cooled to obtain a DDM-modified BMI, and the solid content of the DDM-modified BMI solution is controlled to 60% by the amount of solvent used.

[0068] (2) Preparation of resin composition

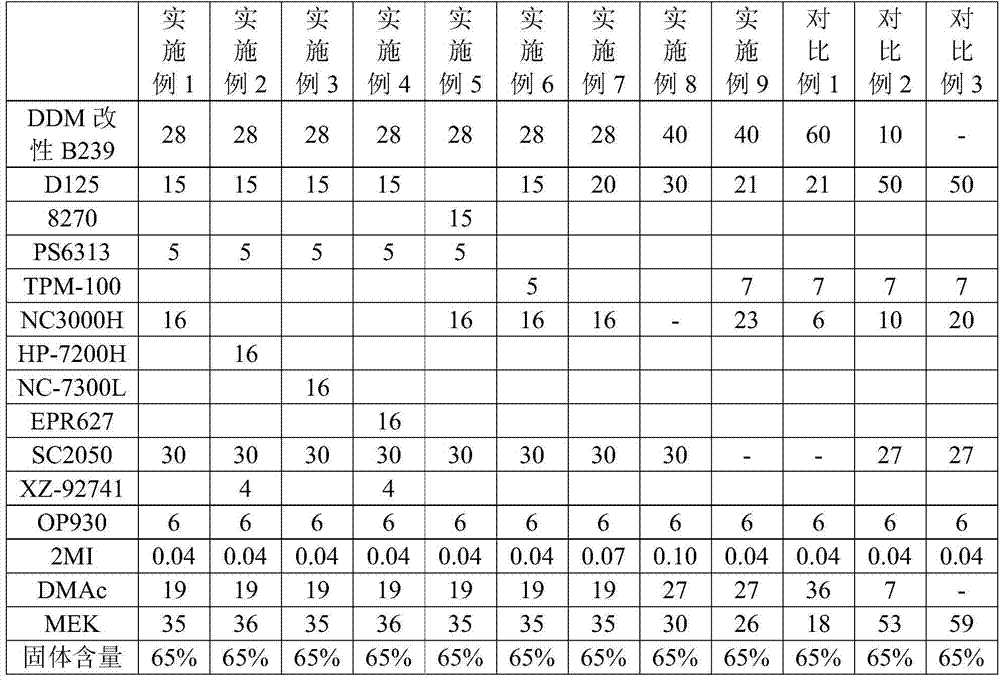

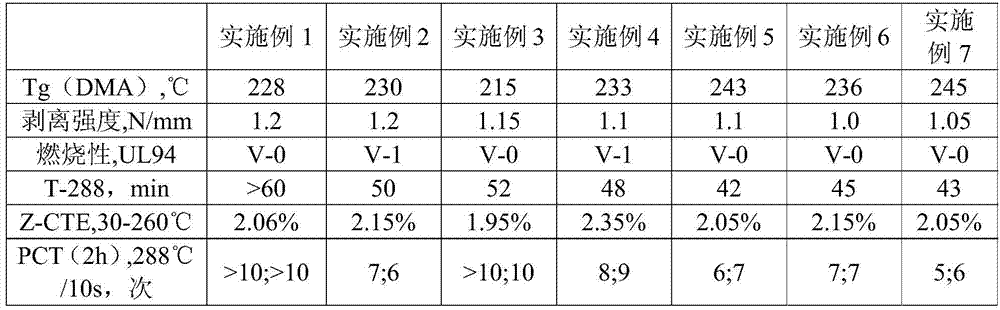

[0069] Feeding according to the material dosage ratio (solid weight) in Table 1 (except for the solvent, it refers to the solid dosage, including DDM modified B239), the specific preparation method is: add DDM modified B23928 parts, D12515 parts, PS to a 1000ml beaker in turn -63135 parts, N...

Embodiment 2

[0075] Example 2, Example 3 and Example 4 were prepared by repeating Example 1 respectively, the main difference being that the epoxy resin was respectively replaced by HP-7200H, NC-7300L, EPR627, wherein Example 2 and Example 4 also added XZ -92741, the preparation of other steps is substantially the same as in Implementation 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com