B-component of spray film waterproof coating capable of delaying self-polymerization time and preparation method thereof

A spray film waterproofing and self-polymerization technology, applied in coatings and other directions, can solve the problems of short self-polymerization time, construction delay, material loss, etc., and achieve the effect of prolonging the self-polymerization time, solving pipeline blockage, and delaying the self-polymerization time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

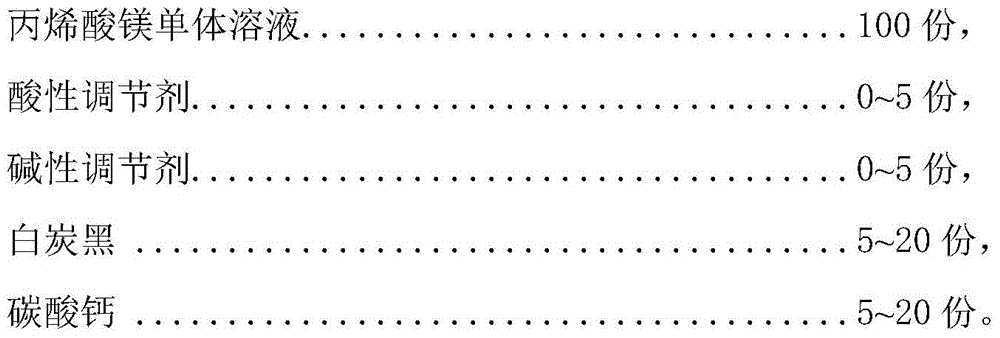

[0026] A kind of spray film waterproof coating B component that the present invention proposes can delay self-polymerization time, its raw material comprises by weight:

[0027] Magnesium Acrylate Monomer Solution................................100 parts

[0028] Silica ..............................................5 parts

[0029] Calcium Carbonate ................................. 5 parts

[0030] Prepare a small amount of pH regulator (within five copies each), and the specific spare materials are as follows:

[0031] Acid regulator - acrylic acid

[0032] Alkaline Conditioner - Sodium Hydroxide

[0033] Its preparation method is:

[0034] Step A: Add 5 parts of white carbon black and 5 parts of calcium carbonate to 100 parts of magnesium acrylate monomer solution, stir with a high-speed disperser, the stirring speed is 900r / min, and the stirring time is 30min;

[0035]Step B: Use a pH tester to detect the pH value of the solution. If the pH value is less than pH6, gra...

Embodiment 2

[0040] A kind of spray film waterproof coating B component that the present invention proposes can delay self-polymerization time, its raw material comprises by weight:

[0041] Magnesium Acrylate Monomer Solution................................100 parts

[0042] Silica .............................................8 parts

[0043] Calcium Carbonate ................................. 8 parts

[0044] Prepare a small amount of pH regulator (within five copies each), and the specific spare materials are as follows:

[0045] Acid regulator - acrylic acid

[0046] Alkaline Conditioner - Sodium Hydroxide

[0047] Its preparation method is:

[0048] Step A: Add 8 parts of white carbon black and 8 parts of calcium carbonate to 100 parts of magnesium acrylate monomer solution, stir with a high-speed disperser, the stirring speed is 1200r / min, and the stirring time is 40min;

[0049] Step B: Use a pH tester to detect the pH value of the solution. If the pH value is less than pH6, gr...

Embodiment 3

[0054] A kind of spray film waterproof coating B component that the present invention proposes can delay self-polymerization time, its raw material comprises by weight:

[0055] Magnesium Acrylate Monomer Solution................................100 parts

[0056] Silica .............................................. 15 parts

[0057] Calcium Carbonate ................................. 15 parts

[0058] Prepare a small amount of pH regulator (within five copies each), and the specific spare materials are as follows:

[0059] Acid regulator - acrylic acid

[0060] Alkaline Conditioner - Sodium Hydroxide

[0061] 10% concentration of sodium hydroxide solution (within 0.3 parts by weight)

[0062] Its preparation method is:

[0063] Step A: Add 15 parts of white carbon black and 15 parts of calcium carbonate to 100 parts of magnesium acrylate monomer solution, stir with a high-speed disperser, the stirring speed is 1400r / min, and the stirring time is 50min;

[0064] Step B: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com