A whole-segment erection method of exposed lattice steel girders in a steel box tie-rod arch bridge

A tie-bar arch bridge and lattice-type technology, which is applied in the field of whole-segment erection of steel box tie-bar arch bridges with open lattice steel girders. Problems such as high risk and high risk of multiple hoisting in bulk to achieve the effect of reducing the workload of high-altitude welding, avoiding typhoon hazards and high-altitude hazards, and reducing occupation time and obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

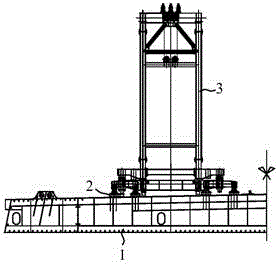

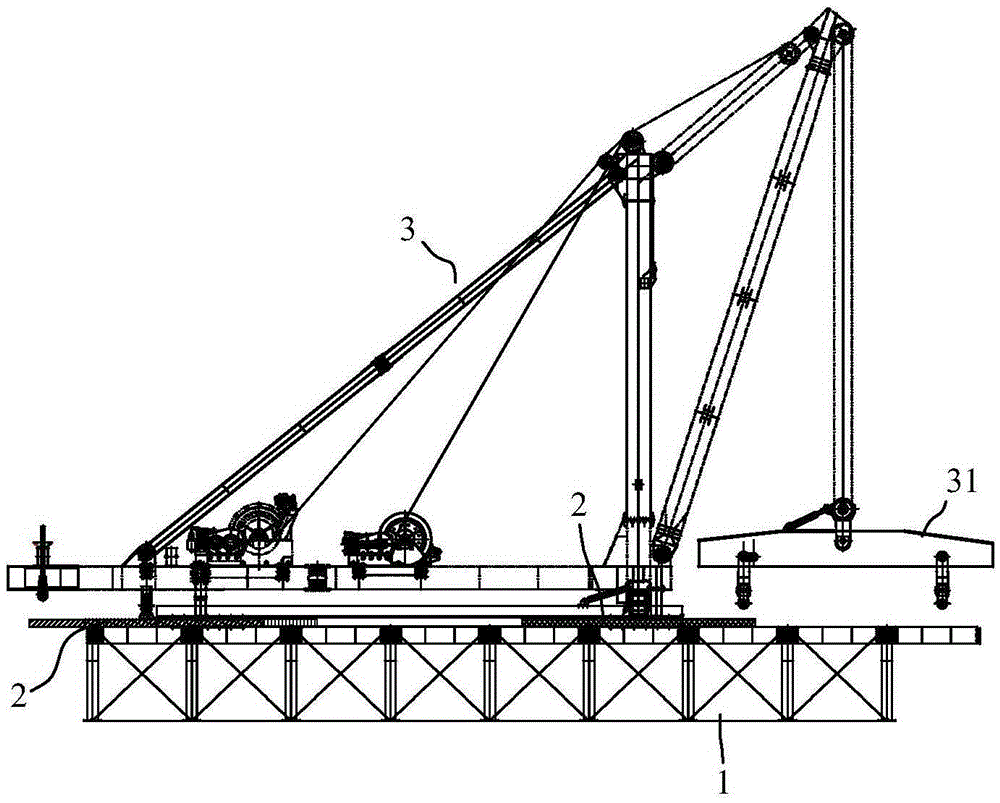

[0040] refer to Figure 1 to Figure 9 , the present invention provides a method for erecting the entire section of an open lattice steel girder of a steel box tie-rod arch bridge, comprising the following steps:

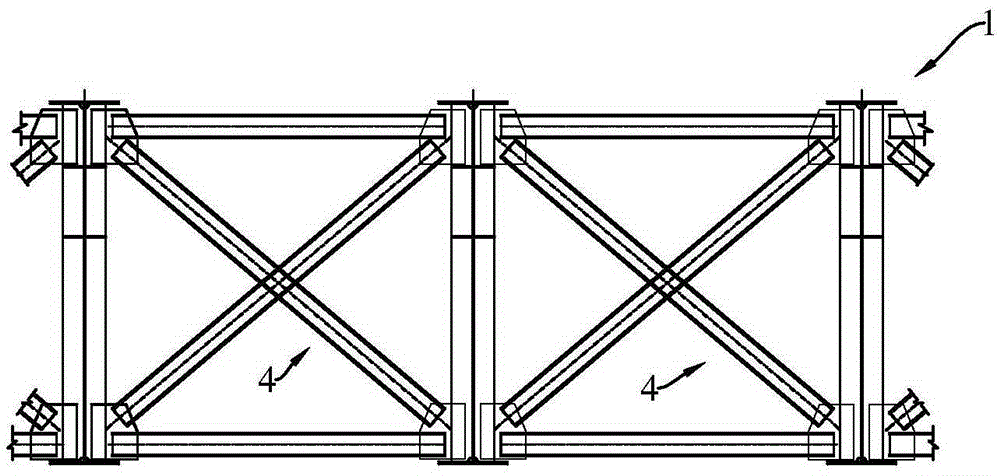

[0041] A. Prefabricated open lattice steel beam section 1 and distribution beam 2. The open lattice steel beam section 1 includes side box girders on both sides and an open lattice structure installed between the side box girders on both sides Structural beams, the open lattice structure beams are composed of several steel beams and steel longitudinal beams to form a frame structure with upper and lower openings. The present invention adopts the method of hoisting the whole segment, which can reduce the workload of high-altitude welding, and the construction speed is fast and safe. low risk;

[0042] B. Assemble two walking beam erecting cranes 3 on the poured concrete bridge surface and then anchor them on the concrete beam for trial lifting. The two walking beam e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com