Section milling type casing pipe sidetracking windowing tool

A casing and sidetracking technology, which is applied in the direction of earthwork drilling, wellbore/well components, etc., can solve the problems of inability to shrink the working surface of the cutter body, poor cutter body strength, and difficult control, so as to reduce the cost of sidetracking window opening , good effect, flexible and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following describes the embodiments of the present invention in detail with reference to the accompanying drawings:

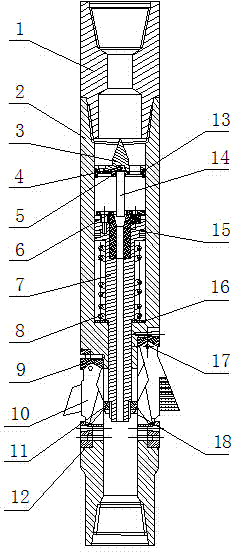

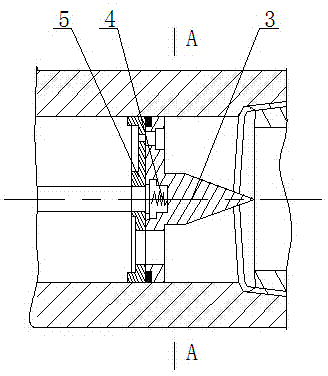

[0020] This section milling type casing side drilling window opening tool is composed of an upper joint 1, a tool body 2, a guide cone 3, a guide cone seat 5, a guide rod 14, and a piston assembly. The upper end of the tool body 2 is installed with a threaded connection. The upper joint 1 and the tool body 2 are equipped with a diversion cone seat 5 on the upper part of the cavity. The diversion cone seat 5 is installed with a diversion cone 3 through bolts and a sealing ring 13, and one end of the diversion rod 14 is made with a boss, and the guide rod 14 The boss is clamped to the lower part of the guide cone 3, a small spring 4 is installed at the connection between the guide cone 3 and the guide rod 14; the lower part of the guide cone seat 5 in the cavity of the tool body 2 is installed with a piston assembly; A tool holder 9 is installed at the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com