Fuel switching device for multi-fuel combustion chamber of gas turbine and control device of fuel switching device

A gas turbine and switching device technology, which is used in gas turbine devices, fuel control of turbine/propulsion devices, jet propulsion devices, etc., can solve the problems of increased jet area and unqualified cooling of the flame tube wall, and achieves optimized design and reduced effective jet flow. Area, the effect of widening the safe working area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

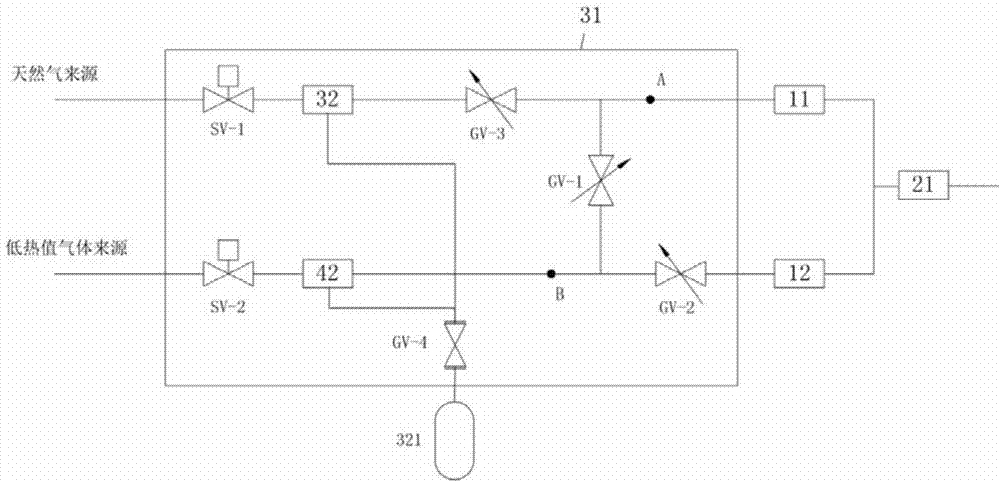

[0033] Such as figure 1 As shown, the gas turbine multi-fuel combustor fuel switching device of this embodiment is characterized in that it includes: a flame tube 21, a natural gas fuel channel 11, a syngas fuel channel 12 and a fuel pre-system 31; a natural gas fuel channel 11 and a syngas The fuel passages 12 are connected in parallel, and the outlets are all connected to the flame tube 21, and the inlets are respectively connected to the fuel pre-system 31;

[0034] The fuel pre-system 31 includes: a natural gas purge system 32 and a synthesis gas purge system 42; the inlet of the natural gas purge system 32 is connected to a natural gas source, and its outlet is connected to the inlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com