Seven-gear single-box three-countershaft transmission

A technology for intermediate shafts and transmissions, which is applied in the direction of gear transmission, transmission control, gear lubrication/cooling, etc. It can solve the problem of low failure rate, achieve low failure rate, facilitate vehicle matching, and ensure the reliability of gear shifting and longevity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

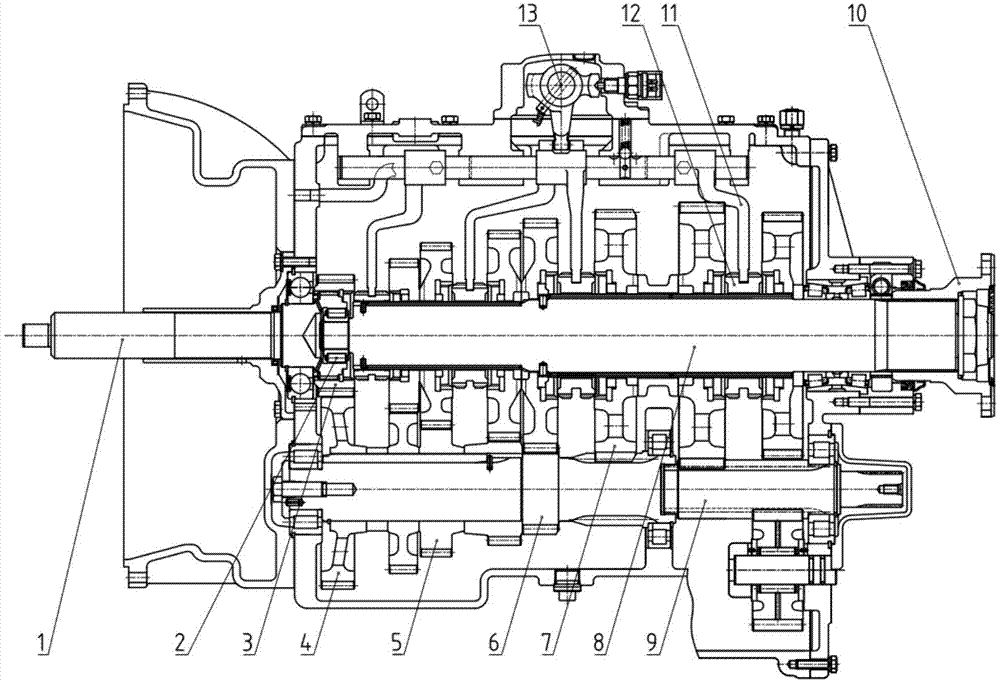

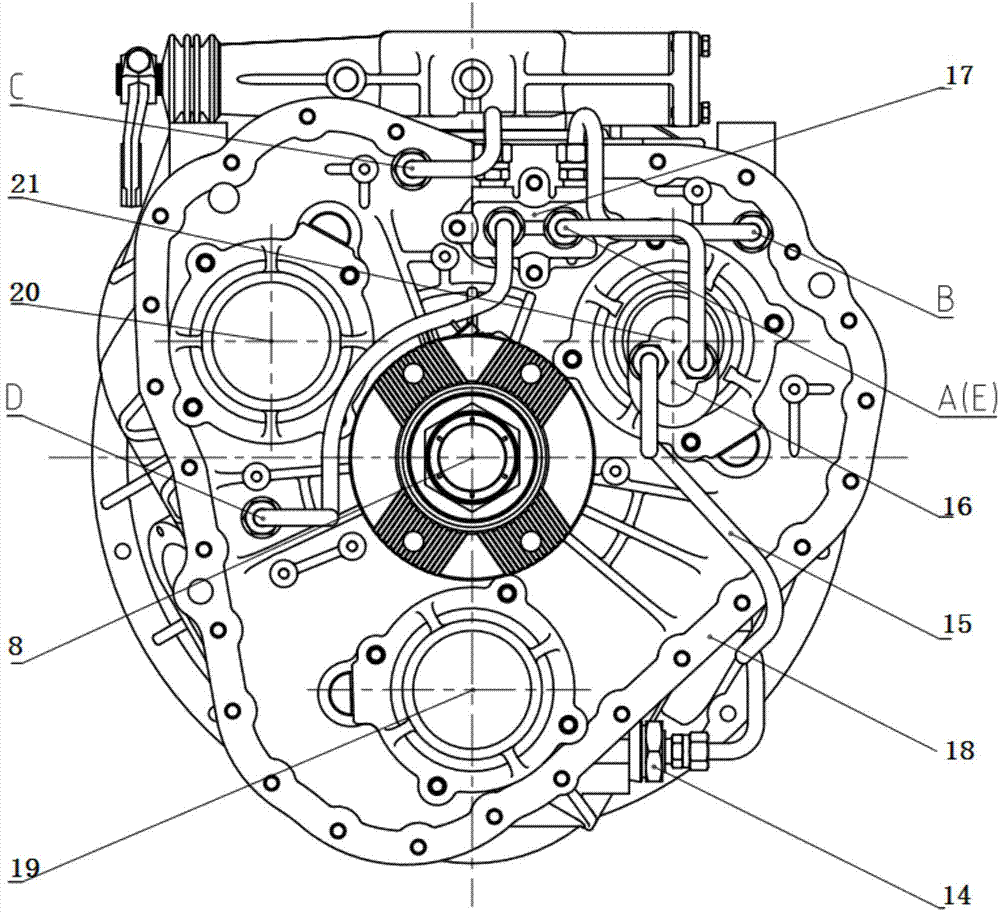

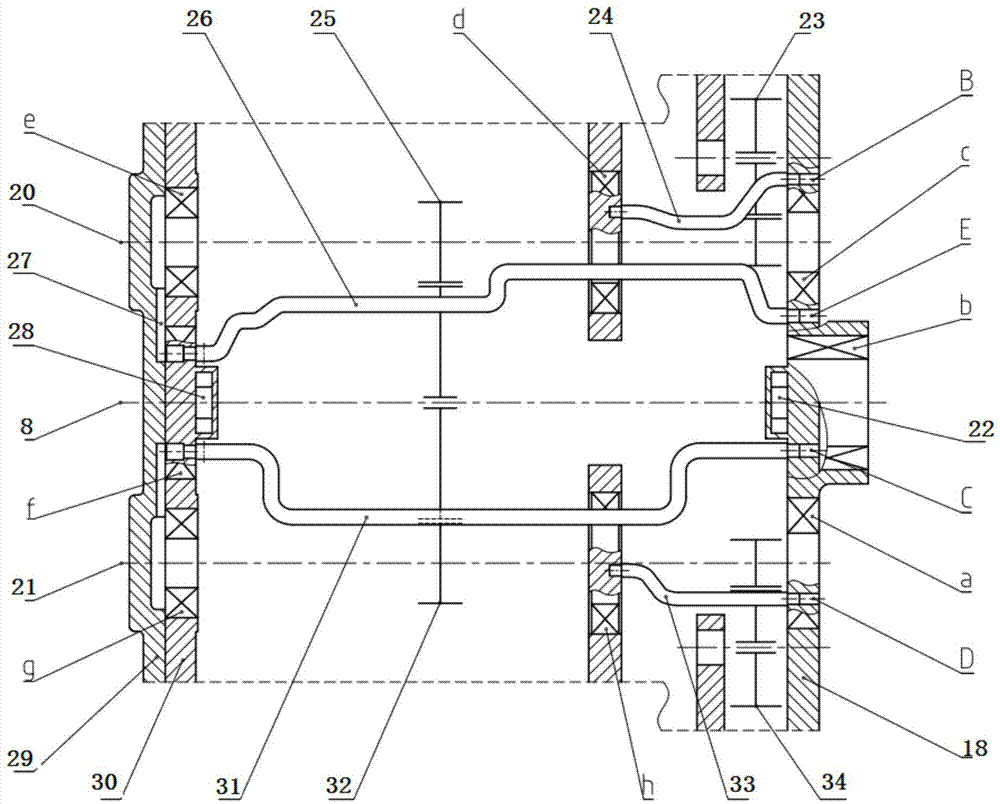

[0028] Such as figure 1 As shown, the seven-speed single-box three-countershaft transmission of the present invention includes an input shaft 1 coaxially arranged front and back, a main shaft 8, three countershafts arranged in pairs around the center of the main shaft 8, and an output flange 10 in the box body 30. Main power transmission components. The input gear 3 is connected to the input shaft 1 through a spline, and is in constant mesh with the front transmission gear 4 of the three intermediate shafts; the main shaft 8 is supported on the rear end of the input shaft 1 through a roller bearing without outer ring 2, and the main shaft gear 7 is sleeved above it. They are in constant mesh with the corresponding intermediate shaft gears 5 on the three intermediate shafts respectively; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com