Accurate measurement method for end jump and planeness of circular saw web

A detection method and technology of circular saw blades, which are applied in the field of precise detection of end jump and flatness, can solve problems such as poor accuracy of detection methods, and achieve fast and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

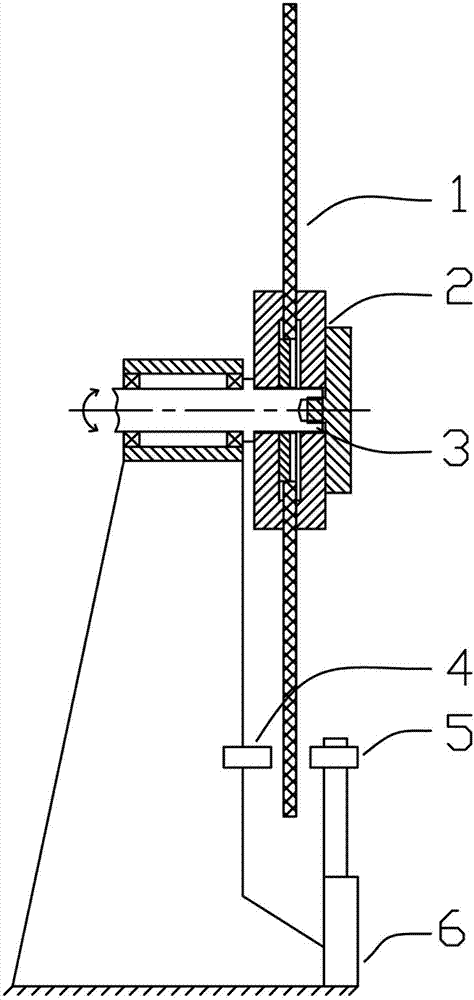

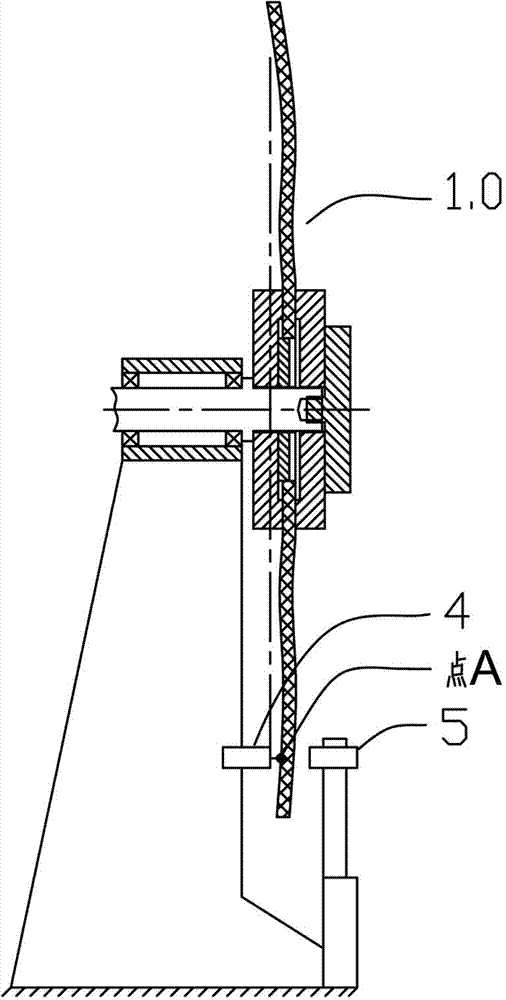

[0020] like figure 1 , 3 As shown in -5, an accurate detection method for the end jump and flatness of a circular saw blade. Before the detection, the surface of the circular saw blade is cleaned, and the circular saw blade 1.0 is centered and fixed to the detection equipment through the flange clamping mechanism 2. On the horizontal shaft 3 connected to the frame 6, the inner displacement detection element 4 and the outer displacement detection element 5 fixed on the frame 6 are respectively located on both sides of the circular saw blade 1.0 and have the same distance from the axis of the horizontal shaft 3, read Take the indication n of the detection point A of the inner surface displacement detection element 4, then remove the circular saw blade 1.0 and turn it over so that the inner surface of the above-mentioned detection faces outwards, then clamp and install it, and adjust the outer displacement detection element 5) so that the indication of the detection point A is ma...

Embodiment 2

[0027] The preferred solution is figure 1 , image 3 -5, the distance between the inner surface displacement detection element 4 and the outer displacement detection element 5 and the axis of the horizontal shaft 3 is (e-10) mm, e is the distance from the bottom of the water tank of the circular saw blade to be measured to the center of the saw blade, this position is measured The end jump value of the circular saw blade has the most practical significance, and the value of the end jump value can basically correspond to the width of the saw gap when cutting.

Embodiment 3

[0029] like Image 6 As shown in -7, in the actual use of this detection method, a single displacement detection element can also be used for detection. It is not necessary to adjust the displacement detection element before batch detection, but each circular saw blade needs to be turned over twice during the detection operation. Clamping, the operation is not as convenient as the method described in Example 1.

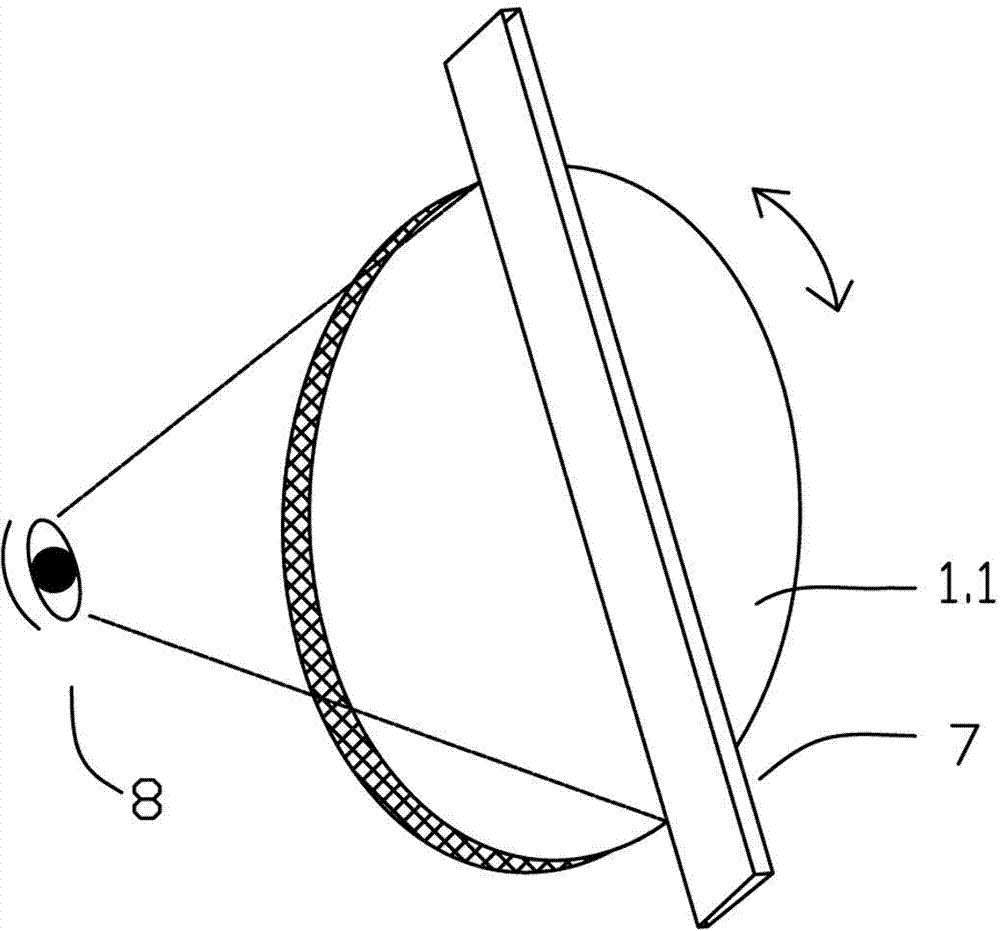

[0030] The details are as follows: an accurate detection method for the end jump and flatness of a circular saw blade. The circular saw blade 1 is centered and fixed on the horizontal rotating shaft 3 connected to the detection equipment frame 6 through the flange clamping mechanism 2, and then fixed. The displacement detection element 4.1 on the frame 6 is located on the inner side of the circular saw blade 1. Rotate the clamped circular saw blade 1.1 for at least one turn, read the reading range p1 to q1 of the detection element 4.1, and then turn the circular saw b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com