A new method and device for measuring the water depth and level of a mechanical coal mine water tank

A water level measurement, mechanical technology, applied in the direction of measuring devices, instruments, etc., can solve the problem of inability to accurately measure the water depth, water level and slime thickness of coal bunkers, and achieve the effect of digital monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

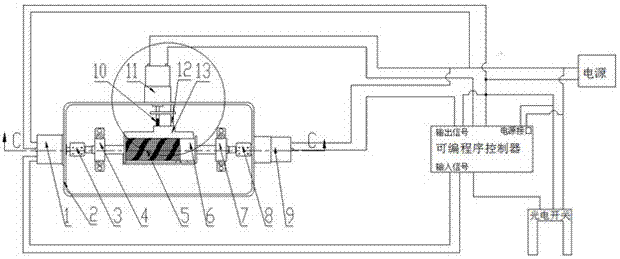

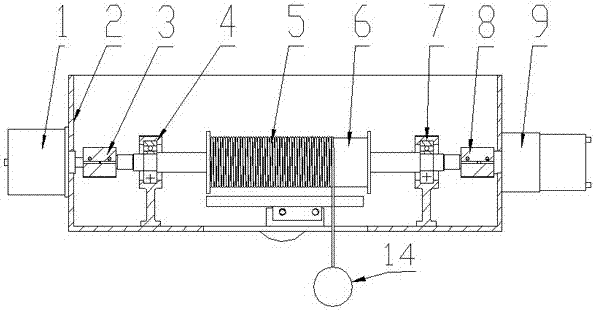

[0030] A new type of mechanical coal mine water tank water depth and water level measuring device such as figure 1 , consists of photoelectric encoder 1, housing 2, left coupling 3, left bearing support 4, steel wire rope 5, drum 6, right bearing support 7, right coupling 8, drum motor 9 to form a drum lifting device.

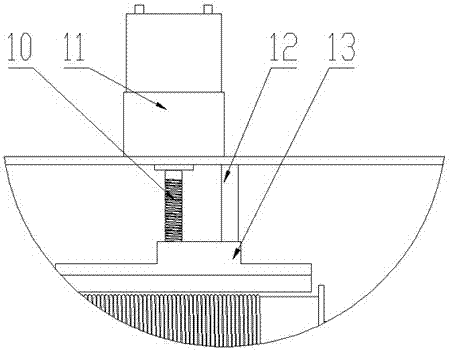

[0031] The clamping device is composed of a screw 10, a clamping motor 11, a polished rod 12 and a clamping baffle 13.

[0032] Such as figure 2 , the drum motor 9 is connected to the drum 6 through the right coupling 8, and the drum 6 is wound with a steel wire rope 5, and the drum motor 9 rotates to drive the drum 6 to rotate, so as to realize the action of retracting the wire rope 5, and finally the weight 14 is lifted; at the same time, the drum 6 The shaft is connected with the photoelectric encoder 1 through the left shaft coupling 3, and the rotation angle of the drum 6 is detected in real time by the photoelectric encoder 1.

[0033] Such as image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com