A temperature control method of refrigeration structure based on integrated dewar assembly variable temperature test

A Dewar component, an integrated technology, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problem of shortening the packaging cycle, and achieve the effects of stable results, simple implementation methods, and high test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

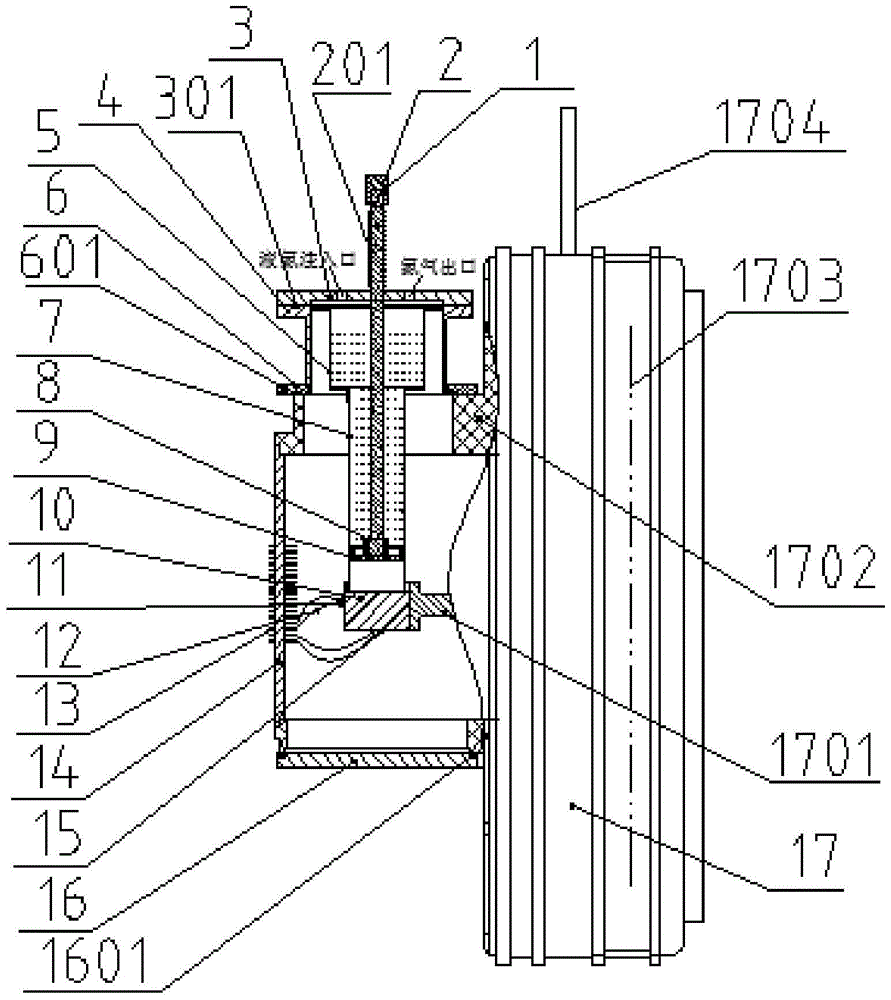

[0048] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

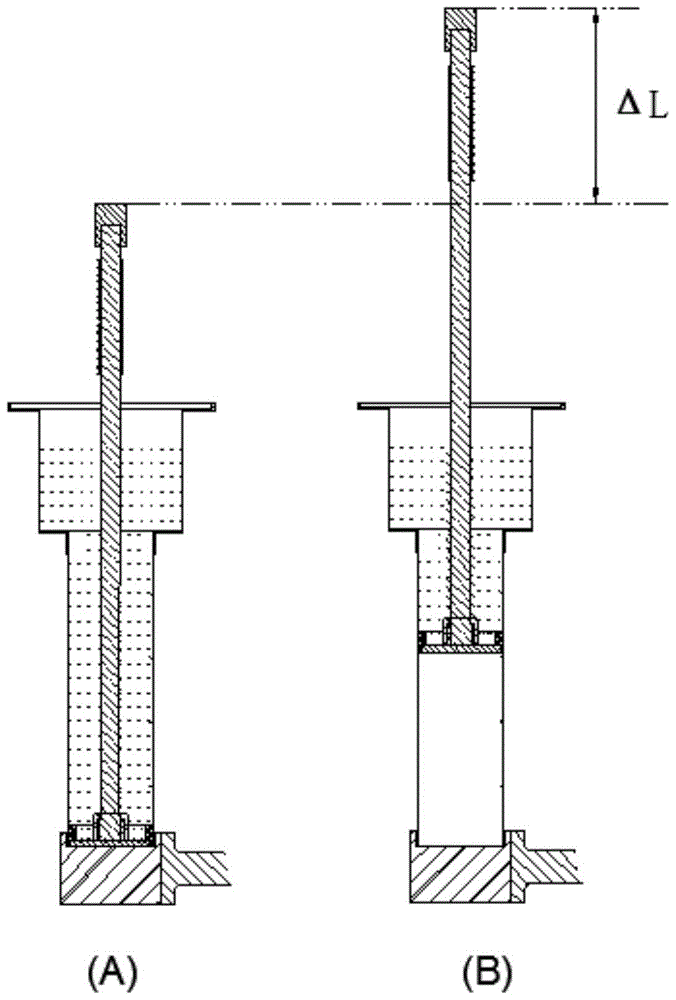

[0049] The embodiment is a performance test of an ultra-long line infrared detector focal plane integrated Dewar component detector, as attached figure 1 As shown, its main implementation method is as follows:

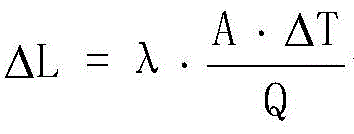

[0050] 1. The preparation method and assembly sequence of each part of the refrigeration structure used in the variable temperature test in the integrated Dewar assembly in the present invention are as follows:

[0051] a) The core column 7 is made of stainless steel 304L material, the wall thickness is 0.15mm, and the outer surface is polished. This part plays the role of liquid nitrogen storage refrigeration and low solid conduction heat leakage. The material of the cold head 10 is high conductivity oxygen-free copper, and the outer surface is polished. The lower end of the core column 7 and the cold head 10 are connected by vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com