10-kv three-core cable finite element thermal analysis method

A three-core cable, thermal analysis technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as inability to obtain accurate temperature field results, achieve intuitive and convenient modeling process, wide practical value, reduce Effects of Modeling Workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with specific examples.

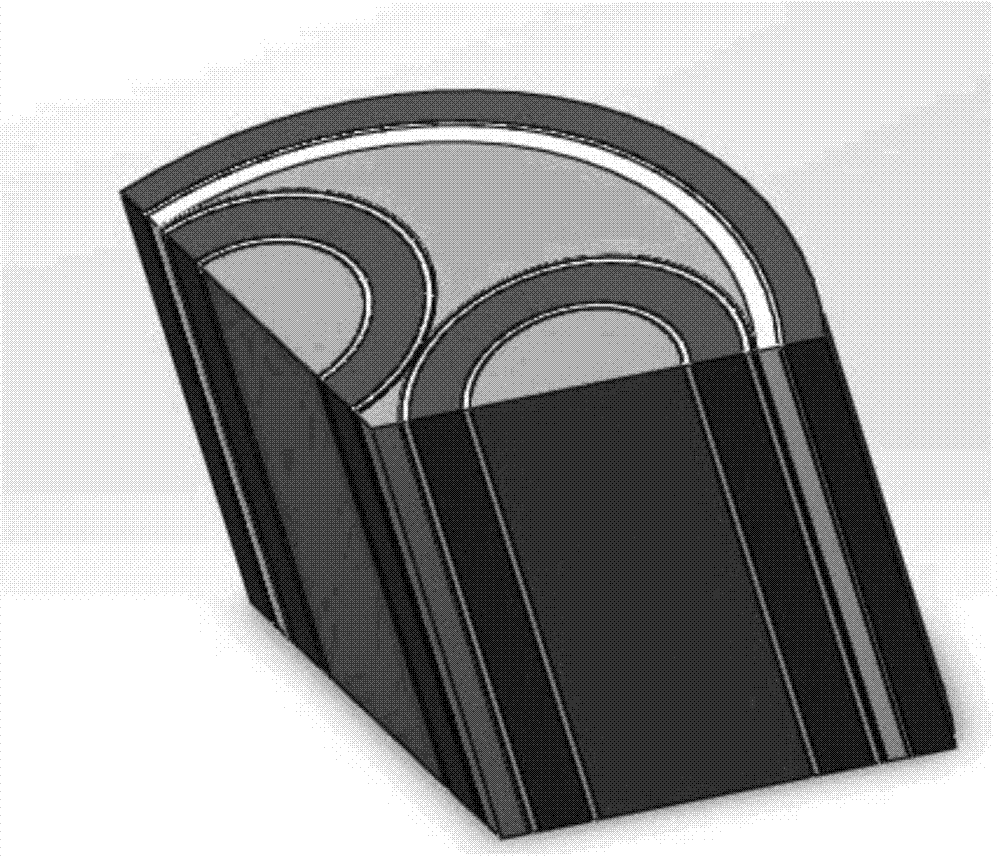

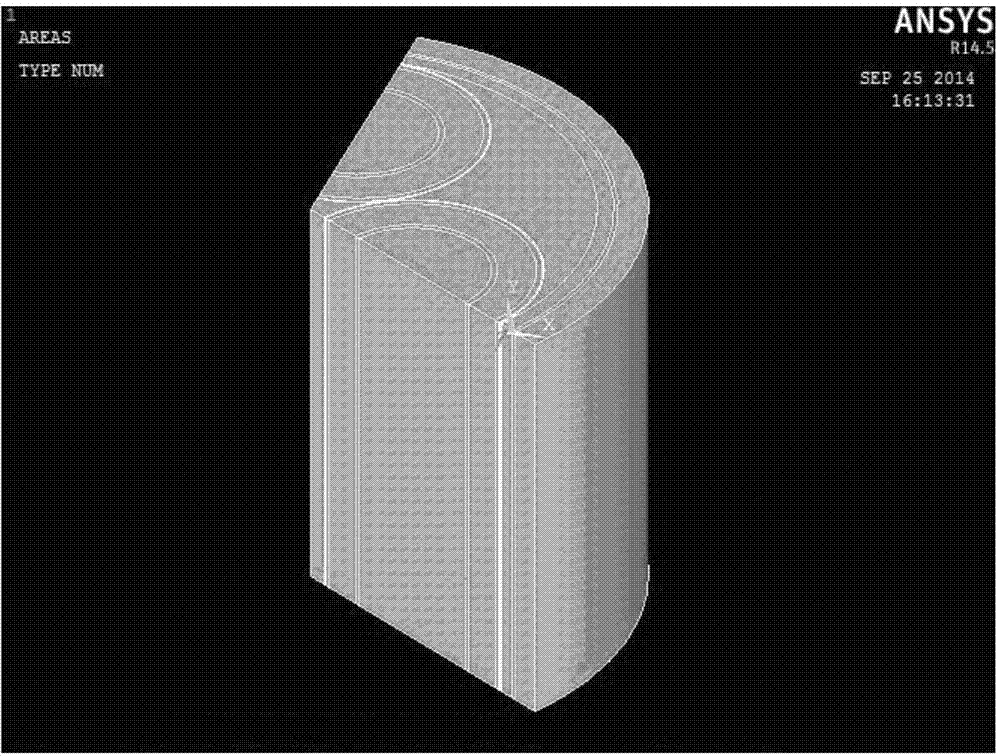

[0069] The principle of the 10kV three-core cable finite element thermal analysis method described in this embodiment is that the temperature field in heat transfer can be solved according to the symmetry, and one-third of the radial direction of the three-core cable is taken for analysis, and the split surface is used as the insulation surface Processing, the solution result will be the same as the temperature field obtained by solving the overall structure. This processing method can effectively shorten the solution time and reduce the computer configuration requirements. The details are as follows:

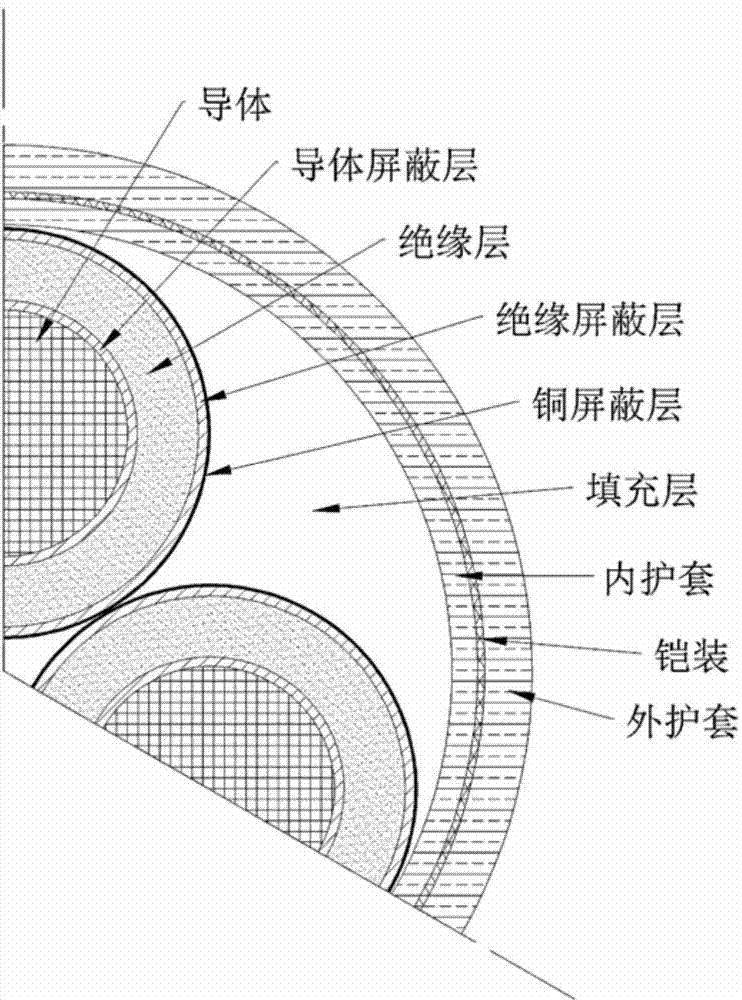

[0070] 1) Determine the geometric structure, size, and material parameters of the 10kV three-core cable, including the core, inner semiconductive layer, insulating layer, outer semiconductive layer, copper shielding layer, filling layer, inner sheath, and armor of the 10kV thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com