Manufacturing device and method for USB connectors

The technology of a manufacturing device and manufacturing method, which is applied in the field of USB connector manufacturing devices, can solve the problems of difficulty in improving the assembly efficiency of automatic assembly machines, high cost and maintenance costs, and difficulty in identifying defective products, so as to reduce the cost of USB manufacturing equipment and equipment Effects of maintenance cost, improvement of assembly efficiency, and simplification of assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Before explaining the technical solutions of the various embodiments of the present invention in detail, the terms and terms involved will be explained. It should be noted that in this specification, components with the same name or the same number represent similar or identical structures, and are for illustrative purposes only.

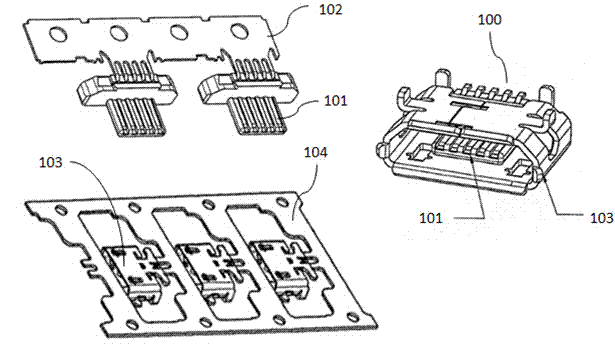

[0030] figure 1 An assembly mechanism diagram of the USB connector is shown. Such as figure 1 As shown, the USB connector 100 includes a USB terminal 101 and a USB housing 103; for the convenience of production and assembly, before assembly, a plurality of USB terminals 101 are connected to the USB terminal strip 102, and a plurality of USB housings 103 are connected to the USB on the shell strip 104 . Positioning slots or protrusions are provided on the USB terminal 101 and the USB housing 103 for positioning and engaging when assembling the USB housing and the USB terminal. Among them, a plurality of USB terminals 101 and the USB termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com