Gap-type heating device and heating method for upper guide-slip rotor of large-scale hydroelectric generating set

A technology for guide-slip rotors and generator sets, applied in electromechanical devices, manufacturing motor generators, electric components, etc., can solve problems such as difficult temperature control, cumbersome wiring, easy to burn surfaces, etc., to reduce the possibility of uneven heating, Reduce on-site unsafe factors and save the effect of temperature measurement work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

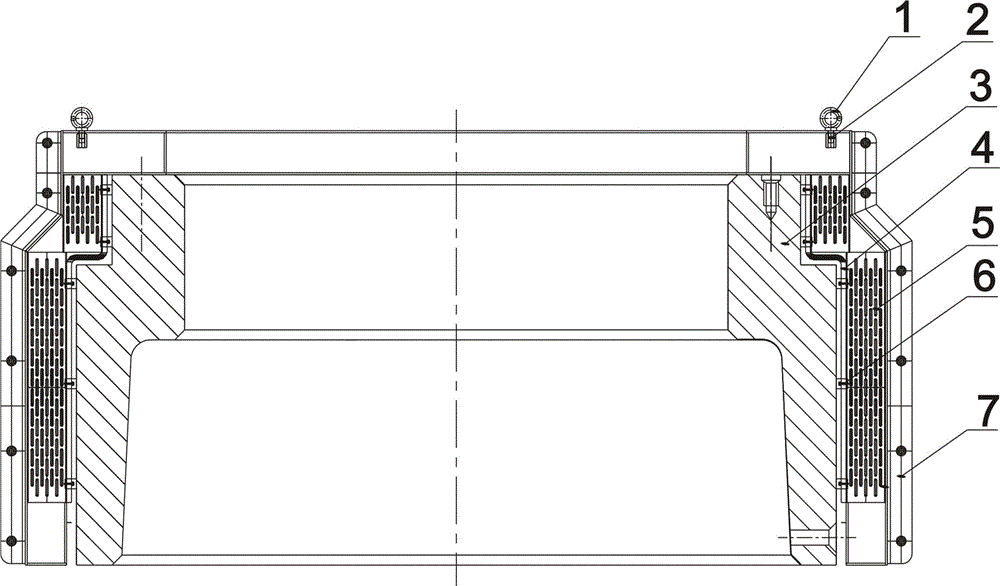

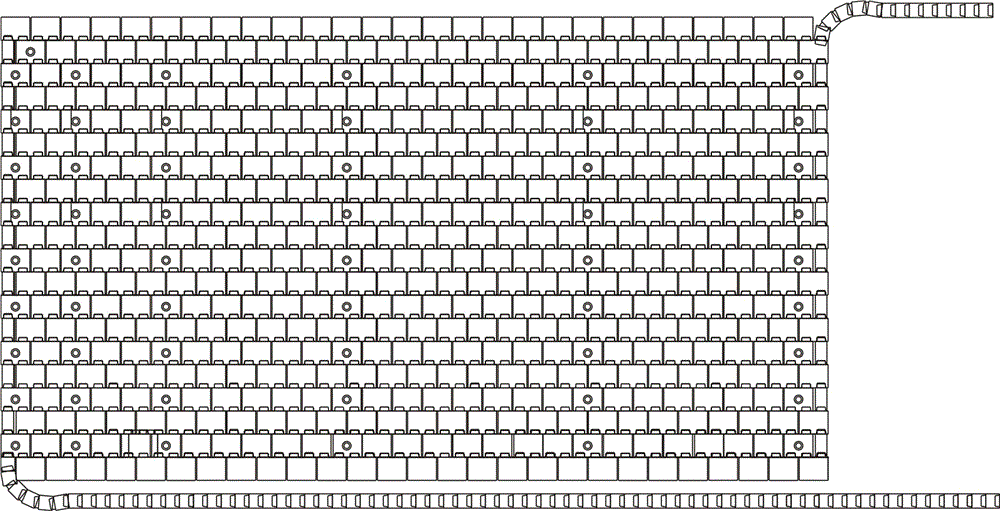

[0033] 1) Lift the electric heating unit in the heating unit 4 one by one, and fasten the upper end of the upper guide rotor 3. The upper guide rotor 3 is a detachable structure. Every time a heating unit is installed, the lifting ring of the upper guide rotor 3 needs to be rotated. to prevent the electric heating unit from slipping;

[0034] 2) Adjust the gap between the heating assembly 4 and the upper guide rotor 3 to 10mm, and then use the limit screw 6 to fix the adjacent electric heating unit to make it a whole;

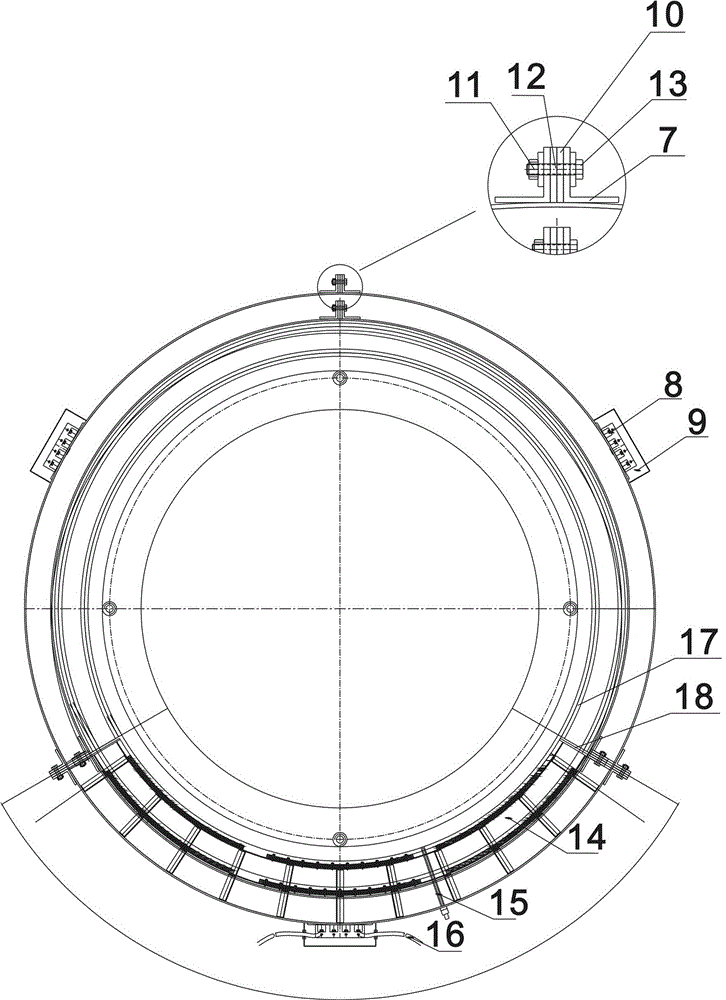

[0035] 3) The heating assembly 4 is composed of three petal heating units, each petal heating unit is separated by a detachable gap adjustment piece 12, and the gap adjustment piece 12 is added or removed to adjust the gap between each petal heating unit to 10mm, and fixed with countersunk screw 13;

[0036] 4) Close the heat preservation base and heat preservation upper cover, open the junction box 9, connect the rubber sheathed cable 11 to the thyristor temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com