Multi-stage telescopic arm device and deep-digging excavator comprising multi-stage telescopic arm device

A telescopic arm and telescopic cylinder technology, applied in the field of deep digging excavators, can solve the problems of increased mass, increased mass of the telescopic arm, and increased frequency of telescopic rope replacement operations, etc., to achieve the goal of improving the bending strength and prolonging the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

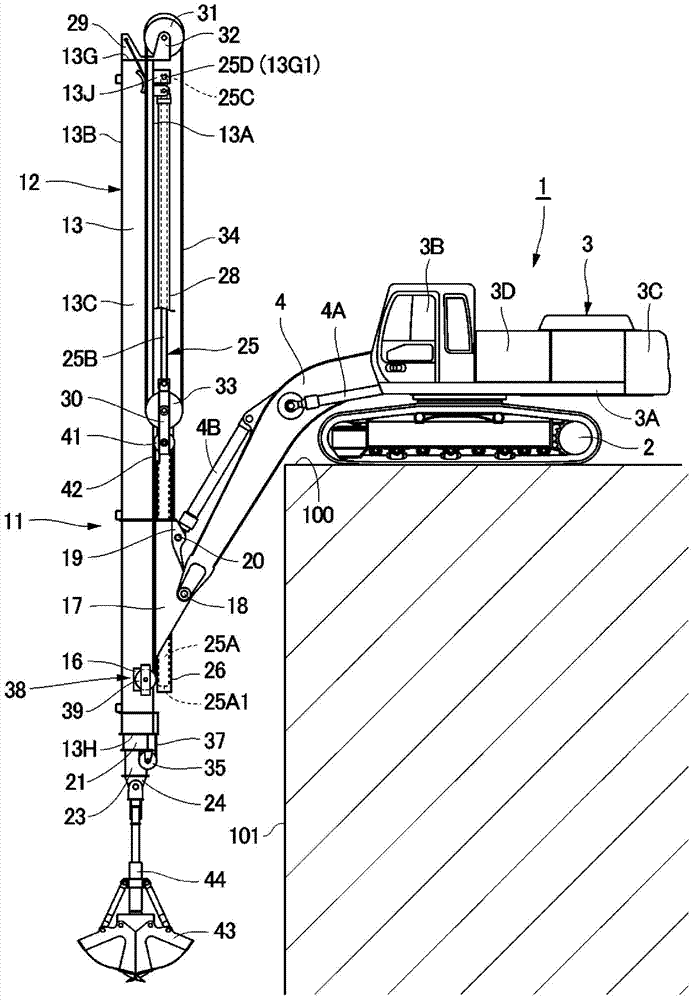

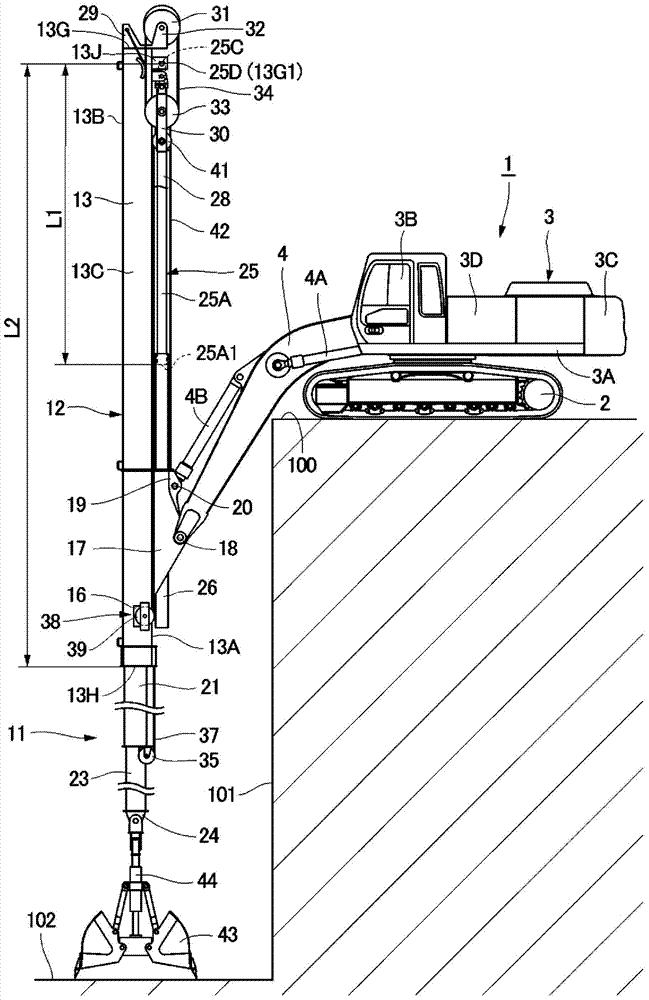

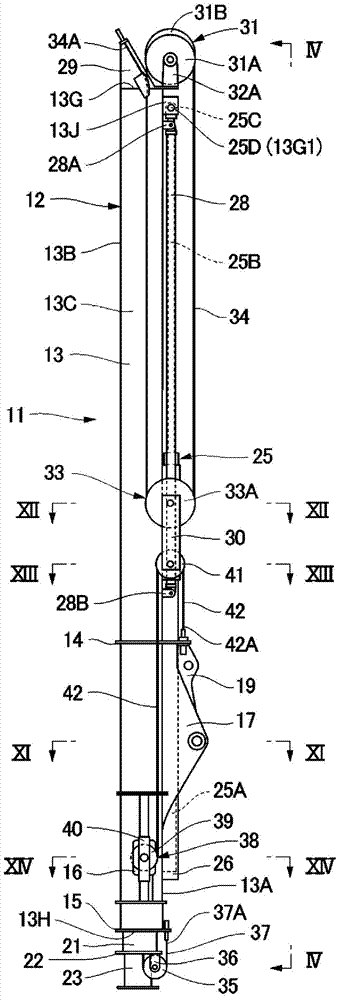

[0060]Hereinafter, embodiments of the deep excavator according to the present invention will be specifically described with reference to the drawings.

[0061] exist figure 1 Among them, reference numeral 1 denotes a deep digging excavator according to the present embodiment. The deep digging excavator 1 has a vehicle body composed of a crawler-type undercarriage 2 capable of self-propelling and a rotatably mounted undercarriage 2 . The upper rotating body 3 constitutes. This vehicle body is an object to be attached to the multi-stage telescopic arm device 11 described later.

[0062] The upper revolving body 3 is roughly composed of the following parts: a revolving frame 3A as a base; a cab 3B arranged on the front left side of the revolving frame 3A; a counterweight 3C provided on the rear end side of the revolving frame 3A; A structure chamber cover 3D in which mounted equipment such as an engine and a hydraulic pump (none of them is shown) is housed therein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com