Grain harvesting machine with good power performance

A technology of power performance and harvesting machinery, applied in the direction of harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of uncompact structure, scattered transmission parts, high maintenance costs, improve maneuverability, and be less prone to failure and damage. , to ensure the effect of the transmission structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

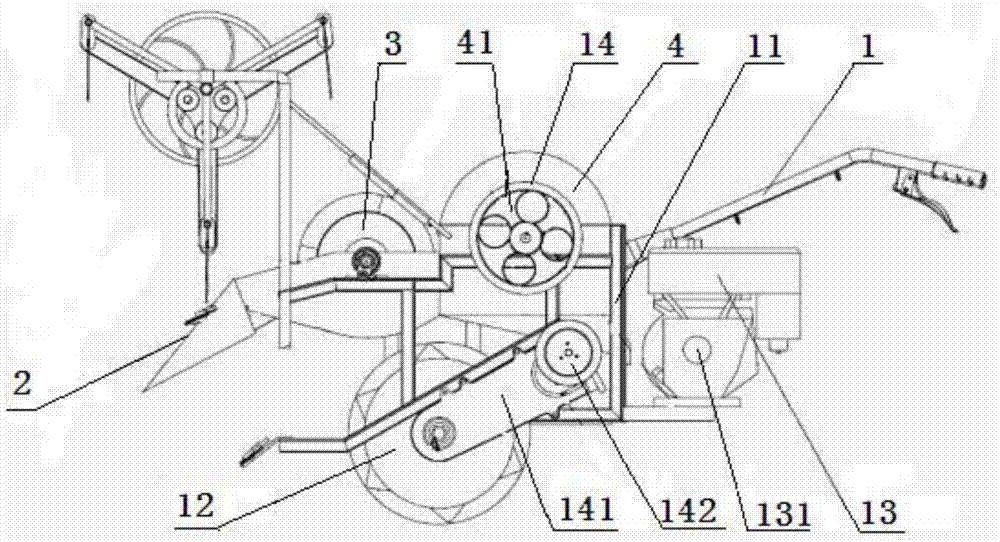

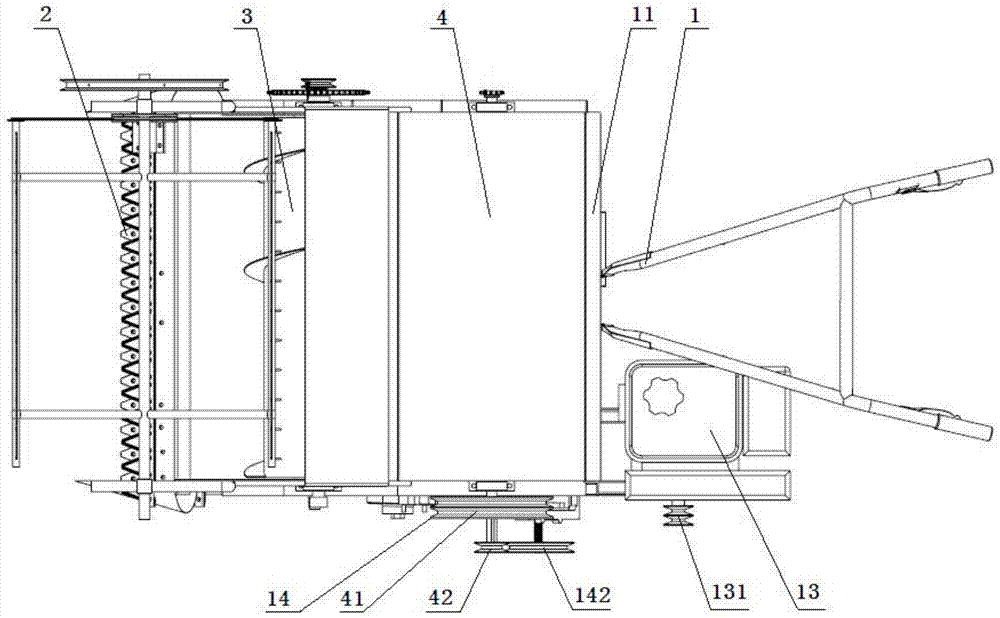

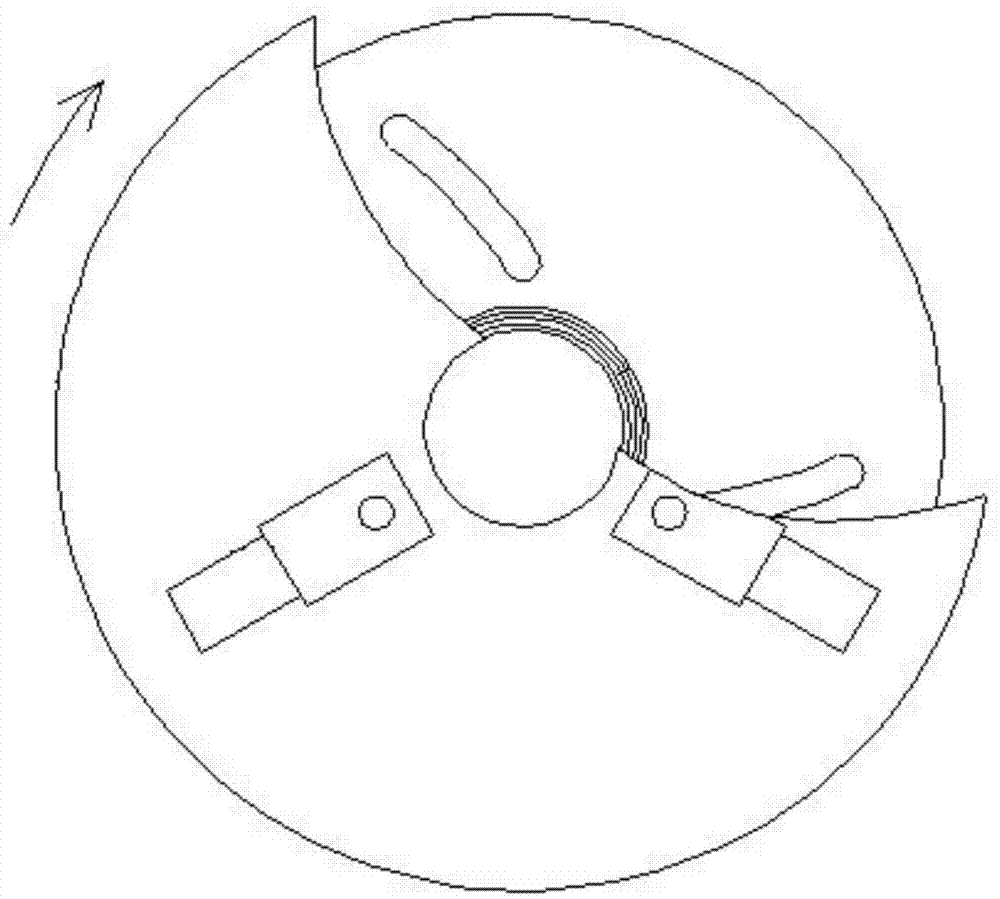

[0017] figure 1 It is the front view of the present invention, figure 2 It is a top view of the present invention, image 3 It is a schematic diagram of the flywheel structure, as shown in the figure: the grain harvesting machine with good power performance in this embodiment includes a self-propelled car body 1 and a harvester 2 installed on the self-propelled car body 1, a screw conveying device 3 and a drum type Threshing device 4; described self-propelled vehicle body 1 comprises vehicle frame 11, road wheel 12, motor 13 and the power take-off shaft and harvester 2, screw conveying device 3, threshing device 4 and road wheel 12 that are connected to motor 13 The transmission assembly 14, the transmission assembly 14 includes a side-mounted transmission box 141 laterally installed on the side of the vehicle frame 11 for transmitting power to the road wheels 12, the transmission box 141 and the output shaft of the engine 13 are located on the self-propelled vehicle body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com