Preparation method and application of heteroatom modified composite negative electrode material

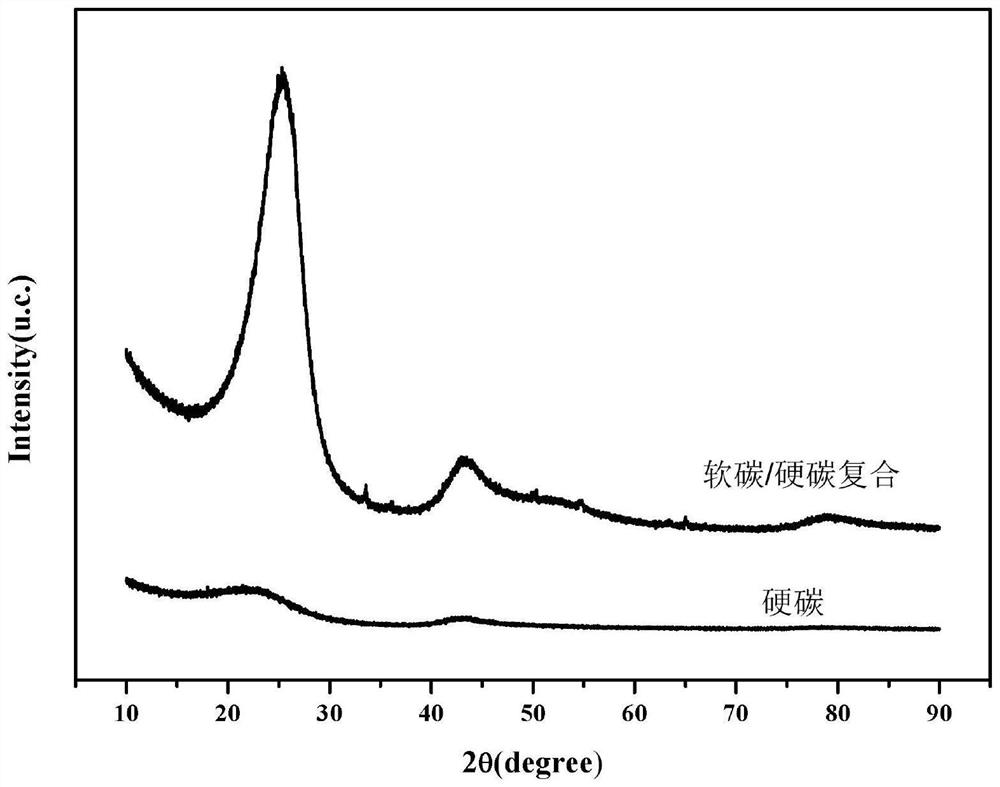

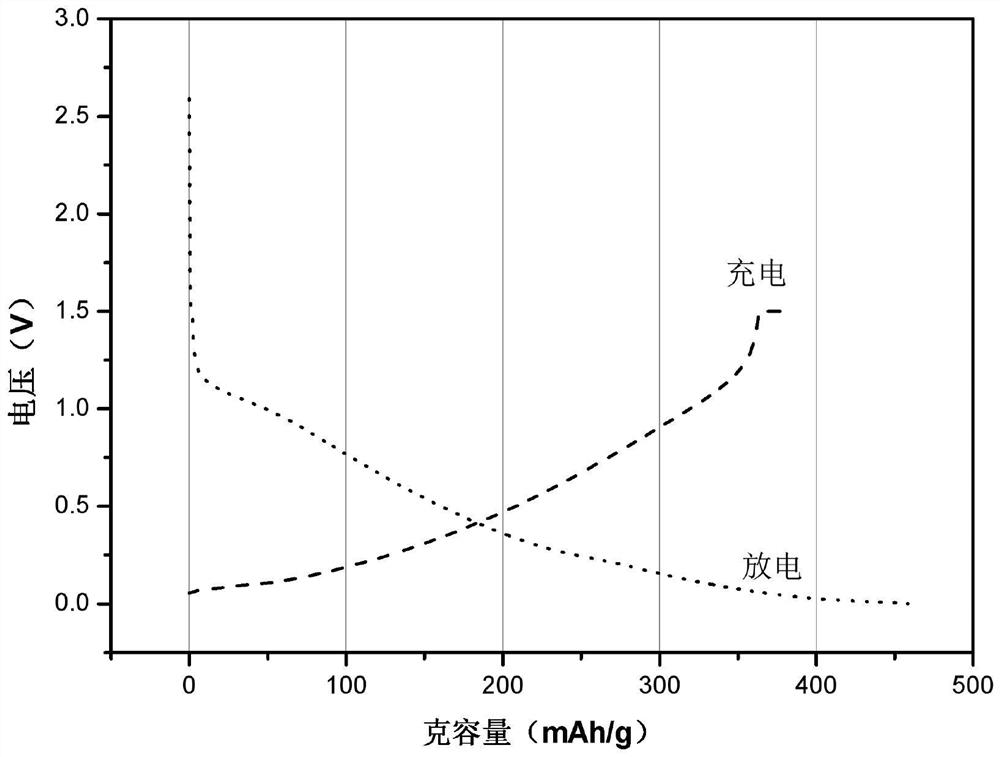

A negative electrode material and heteroatom technology, which is applied in the field of preparation of heteroatom modified composite negative electrode materials, can solve the problems of fewer synthesis steps and complexity, and achieve the effects of large current discharge capacity, increased capacity, and high initial charge and discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a heteroatom-modified composite negative electrode material, specifically comprising the following steps:

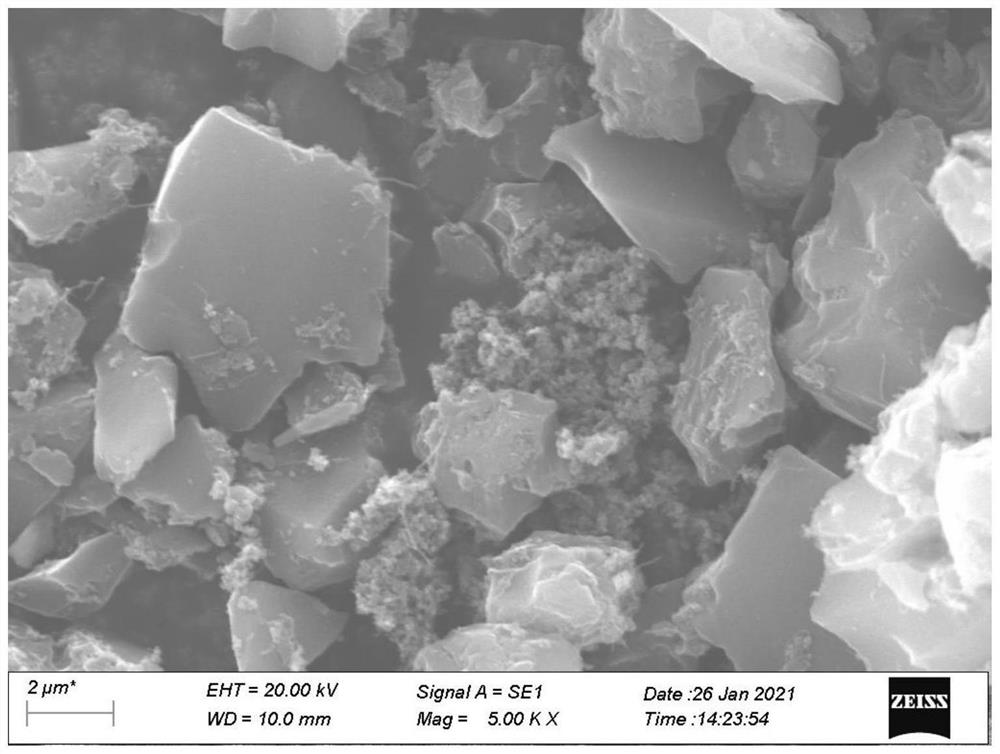

[0038] 1) Precursor preparation: Weigh 8.3g of polytetrafluoroethylene, 24.9g of soft carbon, and 49.8g of hard carbon, mix them, fully melt and stir the above mixture at 300°C for 2 hours, cool it at room temperature, and then crush it into In granular form, a precursor with a particle size of about 4 μm is obtained;

[0039] 2) Chemical vapor deposition: place the precursor in the temperature zone of the CVD tube furnace near the gas outlet, place urea in the temperature zone of the CVD tube furnace close to the gas inlet, and vacuumize the CVD quartz tube after placing it After reaching below 5Pa, the carrier gas argon is introduced at a flow rate of 145 sccm / min, and then the precursor temperature zone is heated, and the nitrogen source temperature zone is heated after approaching 300°C; when the temperature on one side of the nitrogen s...

Embodiment 2

[0041] A method for preparing a heteroatom-modified composite negative electrode material, specifically comprising the following steps:

[0042] 1) Precursor preparation: Weigh 9.1g of polytetrafluoroethylene, 31.85g of soft carbon, and 50.05g of hard carbon, mix them, fully melt and stir the above mixture at 300°C for 2 hours, cool it at room temperature, and then crush it into In granular form, a precursor with a particle size of about 4 μm is obtained;

[0043] 2) Chemical vapor deposition: place the precursor in the temperature zone of the CVD tube furnace near the gas outlet, place the urea in the temperature zone of the CVD tube furnace close to the gas inlet, and vacuumize the CVD quartz tube after placement to achieve After the flow rate is below 5Pa, the carrier gas argon is introduced at a flow rate of 145 sccm / min, and then the temperature zone of the precursor is heated, and the temperature zone of the nitrogen source is heated after approaching 300°C; when the tem...

Embodiment 3

[0045] A method for preparing a heteroatom-modified composite negative electrode material, specifically comprising the following steps:

[0046] 1) Precursor preparation: Weigh 8.3g of polyvinylidene fluoride, 33.2g of soft carbon, and 41.5g of hard carbon, mix them, fully melt and stir the above mixture at 300°C for 2 hours, cool it at room temperature, and then crush it into particles in a jet mill Shape, to obtain a precursor with a particle size of about 4 μm;

[0047]2) Chemical vapor deposition: place the precursor in the temperature zone of the CVD tube furnace near the gas outlet, place urea in the temperature zone of the CVD tube furnace close to the gas inlet, and vacuumize the CVD quartz tube after placing it , after reaching below 5Pa, the carrier gas argon is introduced at a flow rate of 145 sccm / min, and then the precursor temperature zone is heated, and the nitrogen source temperature zone is heated when it is close to 350°C. When the temperature of one side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com