A light and warm core-spun hollow knitted fabric

A knitted fabric, hollow technology, applied in the field of knitted fabrics, can solve the problems of insufficient warmth, bloated, inconvenient movement, etc., and achieve the effect of multi-warming and comfortable wearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

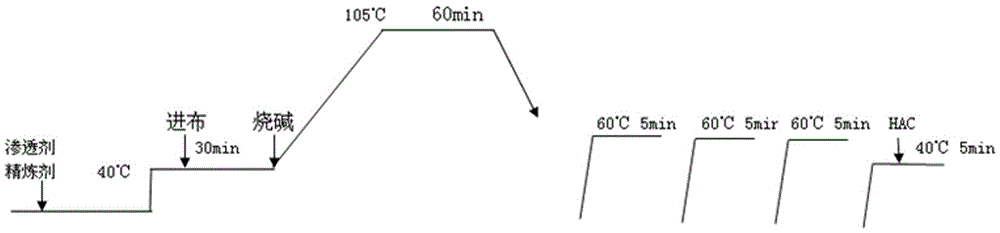

[0024] see Figure 1-4 , in the embodiment of the present invention, a kind of frivolous warm-keeping core-spun hollow knitted fabric, the raw material according to weight percentage comprises: 91% 24s cotton polyester sheath-core blended hollow yarn, 9% 30D DuPont spandex, 91% 24s cotton polyester leather The core blended hollow yarn is composed of 54% cotton fiber, 16% water-soluble vinylon fiber, and 21% 50D / 48FDTY cross-section low elastic yarn.

[0025] The production process of the light and thin warm core-spun hollow knitted fabric, the specific steps are as follows:

[0026] (1) Taking materials: Weigh each raw material according to weight percentage;

[0027] (2) Wrapped yarn: Mix cotton fiber and water-soluble vinylon fiber evenly according to the weight ratio of 75:25, and then core-wrap 50D / 48FDTY cross-section low-elastic yarn to obtain gray yarn;

[0028] (3) Weaving gray yarn: use rib machine to weave 24s cotton polyester skin-core blended hollow yarn and 30D ...

Embodiment 2

[0035] see Figure 1-4 , in the embodiment of the present invention, a light and thin warm core-spun hollow knitted fabric, the raw materials according to the percentage by weight include: 10% 24s cotton-polyester sheath-core blended hollow yarn, 60% 32s cotton fiber, 20% 32s water-soluble vinylon Fiber, 10% 30D DuPont spandex.

[0036] The production process of the light and thin warm core-spun hollow knitted fabric, the specific steps are as follows:

[0037] (1) Taking materials: Weigh each raw material according to weight percentage;

[0038] (2) Wrapped yarn: Mix cotton fiber and water-soluble vinylon fiber evenly according to the weight ratio of 75:25, and then core-wrap 50D / 48FDTY cross-section low-elastic yarn to obtain gray yarn;

[0039] (3) Weaving gray yarn: use a rib machine to weave 24s cotton polyester skin-core blended hollow yarn and 30D Dupont spandex to obtain gray cloth, the weight of the gray cloth is 290g / SQM, and the door width is 155cm;

[0040] (4) ...

Embodiment 3

[0046] see Figure 1-4 , in the embodiment of the present invention, a light and thin warm core-spun hollow knitted fabric, the raw materials according to the percentage by weight include: 11% 24s cotton-polyester sheath-core blended hollow yarn, 56% 32s cotton fiber, 22% 32s water-soluble vinylon Fiber, 11% 30D DuPont spandex.

[0047] The production process of the light and thin warm core-spun hollow knitted fabric, the specific steps are as follows:

[0048] (1) Taking materials: Weigh each raw material according to weight percentage;

[0049] (2) Wrapped yarn: Mix cotton fiber and water-soluble vinylon fiber evenly according to the weight ratio of 75:25, and then core-wrap 50D / 48FDTY cross-section low-elastic yarn to obtain gray yarn;

[0050] (3) Weaving gray yarn: use a rib machine to weave 24s cotton polyester skin-core blended hollow yarn and 30D DuPont spandex to obtain gray cloth, the weight of the gray cloth is 295g / SQM, and the door width is 160cm;

[0051] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com