Dedusting pipeline for dust containing waste gas

A waste gas and pipeline technology, applied in the direction of external electrostatic separator, electrode structure, electrostatic separation, etc., can solve the problems of hidden safety hazards, low efficiency of explosive dust and dust particle settling, and lack of effective dust removal. , the effect of simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

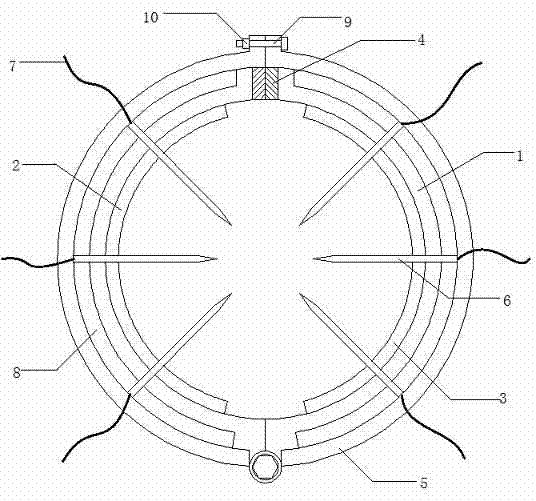

[0018] Such as figure 1 Shown is a schematic structural diagram of the present invention, which is a dust removal pipeline suitable for dusty waste gas, including a waste gas flow pipe and an ionization pipe.

[0019] The exhaust gas flow pipe is formed by rotating and connecting two identical inner pipes 1; the end faces of the inner pipes 1 are arc-shaped, and the inner walls of the two inner pipes 1 are respectively fitted with a positively charged metal plate 2 and a negatively charged metal plate 3, and the two One end of the inner pipe 1 away from the joint is provided with a sealing strip 4 along the axial direction; the pipe wall of the inner pipe 1 is ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com