Heating pipe corner shaping device

A shaping device and heating tube technology, which is applied in the direction of positioning device, feeding device, storage device, etc., can solve the problems of heating tube shape error and low processing efficiency, and achieve the effect of uniform force, high processing efficiency, and not easy to swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

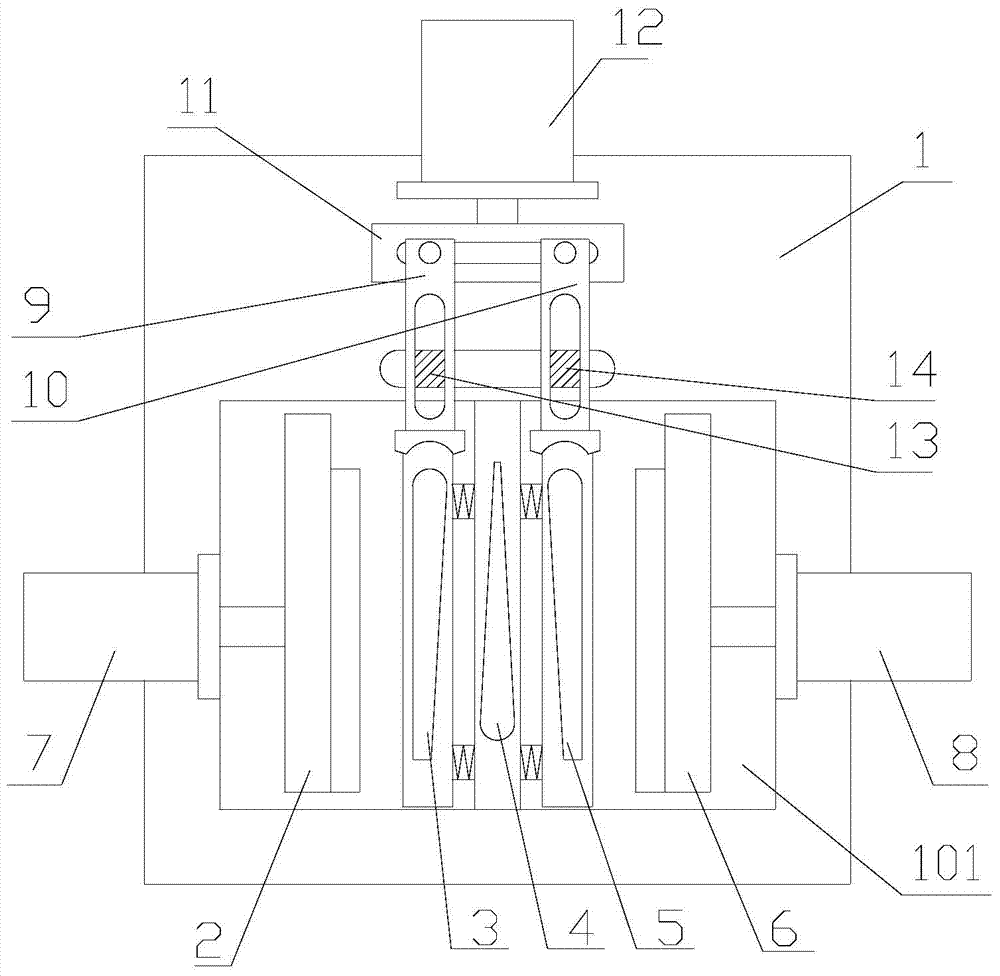

[0017] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a heating tube bending angle shaping device proposed by the present invention.

[0018] refer to figure 1 , the present invention proposes a heating tube bending angle shaping device, including a workbench 1, a first module mounting plate 3, a second module mounting plate 4, a third module mounting plate 5, a first thrust plate 2, and a second thrust plate 6. Pressing mechanism, first driver 7, second driver 8, first slider 13, second slider 14, first pressing plate and second pressing plate;

[0019] The workbench 1 is provided with a first slideway 101, the first thrust plate 2, the first module installation plate 3, the second module installation plate 4, the third module installation plate 5 and the second thrust plate 6 are parallel to each other, and along the first A slideway 101 is sequentially arranged in the first slideway 101 in the length direction, the second module 4 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com