A finite element method for structural analysis of composite beam with initial defects

A technology of structural analysis and finite element, applied in special data processing applications, instruments, geometric CAD, etc., to achieve the effect of improving calculation accuracy, high calculation efficiency, and eliminating concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

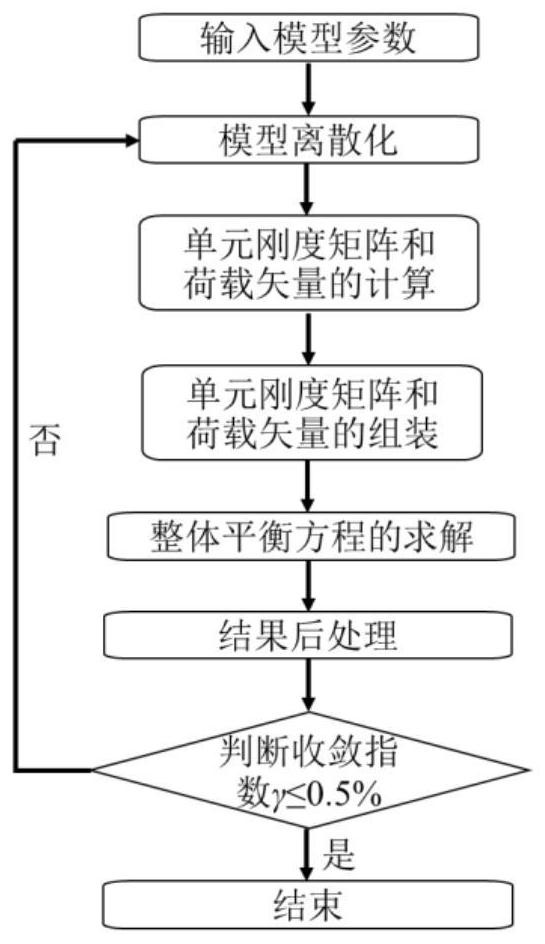

[0075] Such as figure 1 As shown, this embodiment includes the following steps:

[0076] (a) Input model parameters.

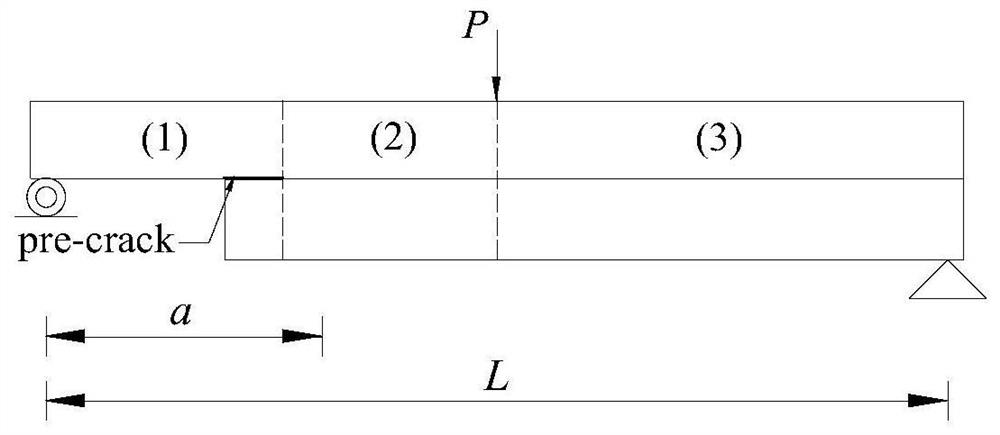

[0077] This embodiment is a static loading simulation of a single leg bending (SLB for short) specimen, such as figure 2 As shown, the length L of the sample is 0.1m, the initial length of the crack is 0.025m, the height of the upper sub-beam ① and the lower sub-beam ② are both 0.002m, and the width is 0.001m. The material parameters of the upper and lower sub-beams are shown in Table 1, and the concentrated load P is 8N.

[0078] Table 1 Material parameters of samples

[0079]

[0080] (b) Discretization of the model.

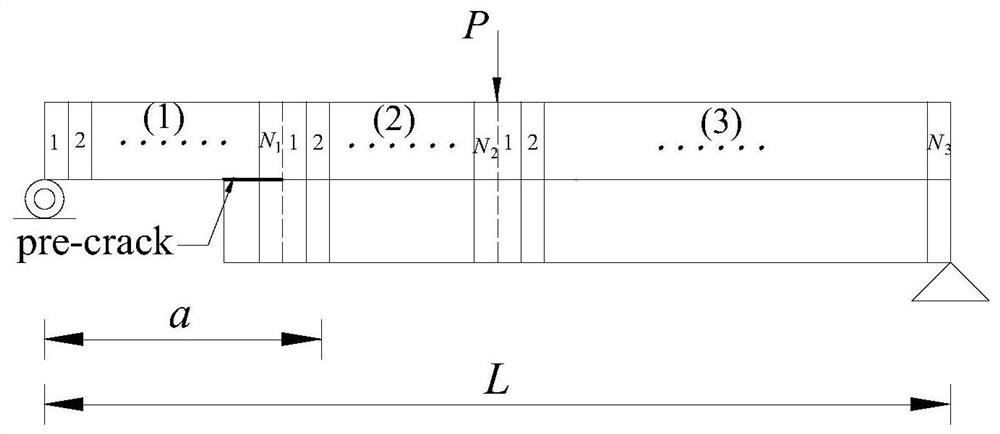

[0081] First will be as figure 2 The shown embodiment SLB sample is divided into 3 areas, i.e. the cracked area (1), the uncracked area (2) on the left side of the loading point (concentrated load P action point) and the uncracked area (3) on the right side of the loading point; Set a certain number of cells per locale, such as ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com