Laminated package material

A technology for packaging materials and thermoplastic materials, applied in the field of laminated packaging materials, can solve the problems of raw material waste, energy waste, etc., and achieve the effects of reduced necking phenomenon, good sealing strength, and rapid heat sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

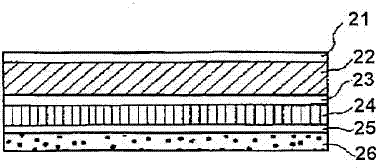

[0022] Such as figure 2 As shown, a laminated packaging material of the present invention includes an outermost layer 21 of a thermoplastic material, a core layer 22, an intermediate layer 23 of a thermoplastic material, a barrier layer 24, an adhesive layer 25 and an innermost layer 26 of a thermoplastic material in order from the outside to the inside.

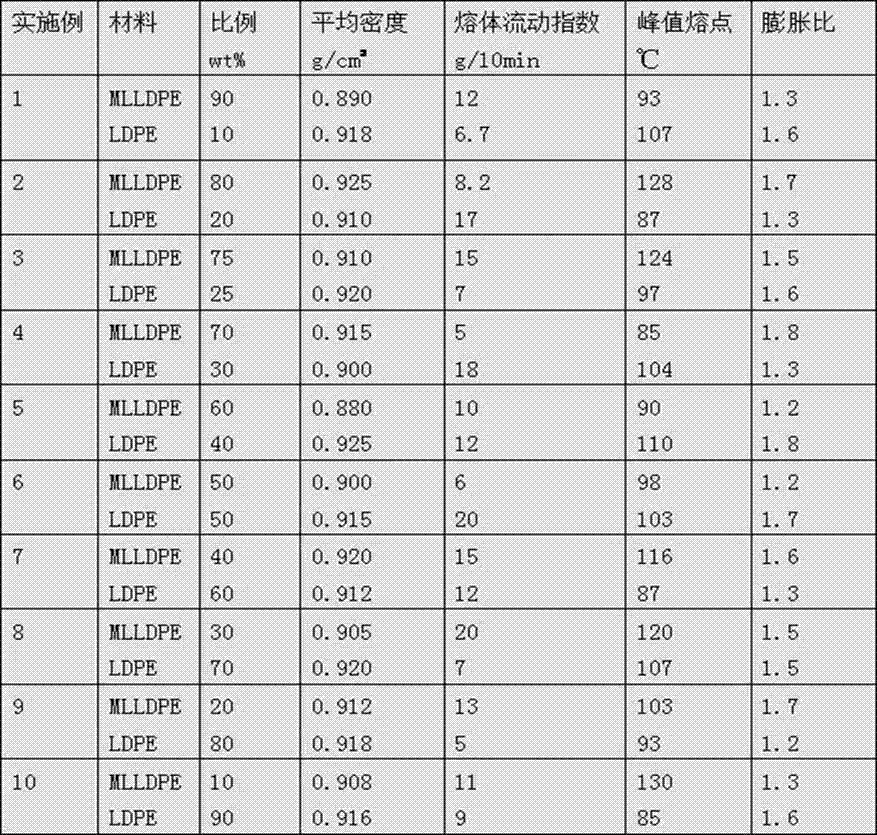

[0023] The innermost layer 26 of the thermoplastic material contains linear low-density polyethylene (MLLDPE) and low-density polyethylene (LDPE) polymerized with a metallocene catalyst, wherein the linear low-density polyethylene (mLLDPE) polymerized with a metallocene catalyst has the following parameters: average density 0.88g / cm 3 ~0.925 g / cm 3 , Melt flow index (190℃, 2.16kg) is 5 g / 10min~20 g / 10min, peak melting point is 85℃~130℃, expansion ratio is 1.2~1.8; low density polyethylene (LDPE) has the following parameters: The average density is 0.90g / cm 3 ~0.925 g / cm 3 , Melt flow index (190℃, 2.16kg) is 5 g / 10min~20 g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com