A linear motion throttle actuator

A technology of accelerator actuator and linear motion, which is applied in transportation and packaging, layout of power plant control mechanism, vehicle components, etc., and can solve the problems of large radial size of deceleration mechanism, reduced service life of zipper, and high installation accuracy requirements, etc. Achieve the effects of small size, easy to use, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

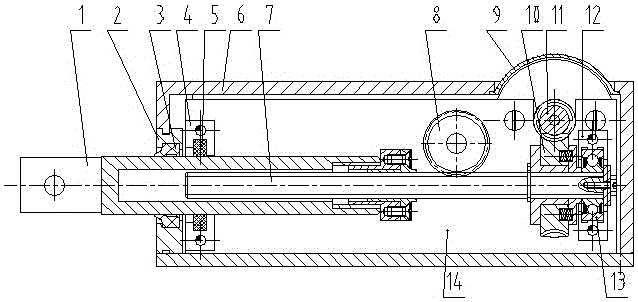

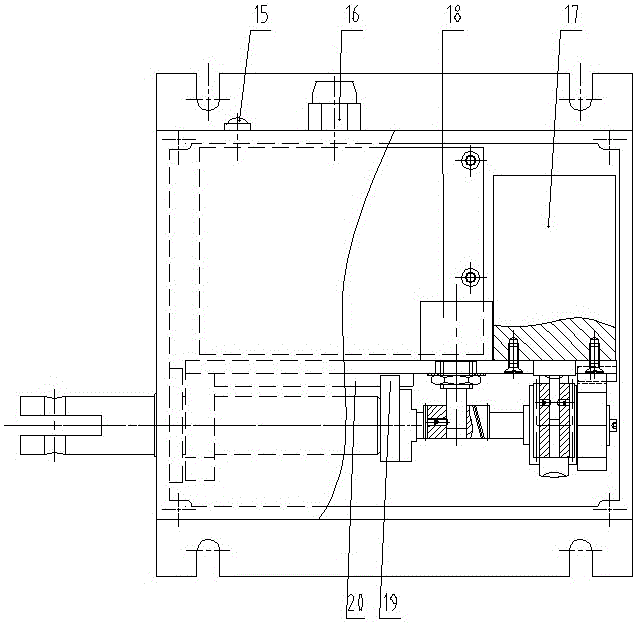

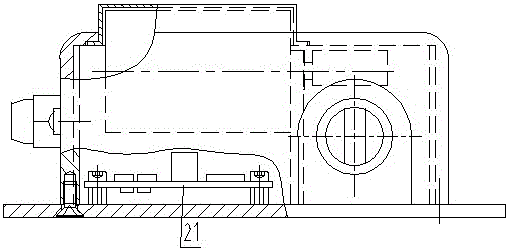

[0021] A linear motion accelerator actuator provided by the present invention, its specific structure diagram is as follows figure 1 , figure 2 , image 3 As shown, it includes a bottom plate 14, a housing 6, a DC motor 18 and a transmission mechanism. The output end of the DC motor 18 is connected to the input end of the transmission mechanism. The transmission mechanism is composed of a reduction mechanism and a screw transmission mechanism. The screw transmission mechanism is composed of a transmission screw 7 and an accelerator push-pull rod 1 screwed together; wherein the throttle push-pull rod 1 is also used as an actuator for pulling the throttle cable.

[0022] A feedback potentiometer 17 is installed on one side of the transmission screw 7 , and the rotation shaft of the feedback potentiometer 17 is fixedly connected with a counting gear 8 , and the counting gear 8 is meshed with the threads of the transmission screw 7 .

[0023] The throttle actuator integrates a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com