Preparation method of high-purity SAPO-44 microporous molecular sieve

A SAPO-44, microporous molecular sieve technology, applied in the field of molecular sieve preparation, can solve the problems of cumbersome preparation process, increase preparation steps, etc., achieve the effect of short cycle, improve crystallinity, and facilitate industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The molecular sieve preparation method of the present invention specifically comprises the following steps:

[0029] (1) Mix the composite template agent, phosphorus source, aluminum source, silicon source, and water evenly to obtain a mixture gel.

[0030] (2) Transfer the gel mixture to a reaction kettle, heat it up to 150-250°C in an airtight manner, and crystallize at a constant temperature under autogenous pressure for a period of time. After the crystallization is complete, cool it down to room temperature naturally.

[0031] (3) The crystallized product is centrifuged, washed until neutral, and dried, and the dried solid product is roasted in the air at 450-650°C to completely remove the composite template agent to obtain SAPO-44 microporous molecular sieve.

Embodiment 1

[0034] Prepare SAPO-44 with tetraethylenepentamine (TEPA) and TMHD double templating agent, the steps are as follows:

[0035] 1. According to the molar ratio of SiO 2 :Al 2 o 3 :P 2 o 5 :TEPA:TMHD:H 2 O=0.75:1:1.25:0.54:2.5:50 Weigh silica sol, pseudoboehmite, phosphoric acid, TEPA, TMHD and water.

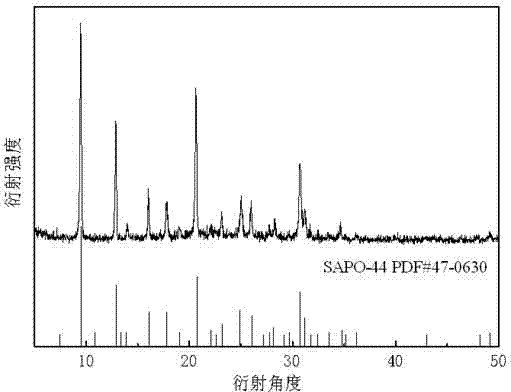

[0036] 2. Dissolve 0.8280g TEPA in 7.2g deionized water, add 2.3058g phosphoric acid, 1.0461g pseudoboehmite, 1.2267g silica sol and 3.4746g TMHD in sequence, and continue stirring for 12 hours. The reactant was transferred to a stainless steel reaction kettle, sealed and heated to 200°C, and then cooled to room temperature naturally after constant temperature crystallization under autogenous pressure for 96 hours. The crystallized product was separated by centrifugation and washed with deionized water several times to neutralize the precipitate. The product was dried in a drying oven at 100°C for 12 hours and calcined in a tube furnace at 550°C for 6 hours to obtain a soli...

Embodiment 2

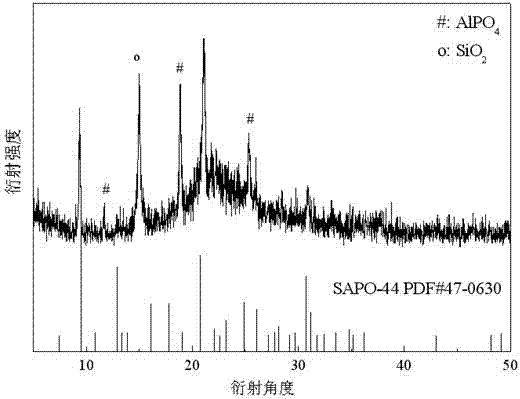

[0038] 1. According to the molar ratio of SiO 2 :Al 2 o 3 :P 2 o 5 :DETA:TMHD:H 2 O=0.8:1:1.2:0.6:2.5:50 Weigh tetraethyl orthosilicate, aluminum oxyhydroxide, phosphorous acid, DETA, TMHD and water.

[0039] 2. Dissolve 0.4952g DETA in 7.2g deionized water. 1.8522g of phosphorous acid, 1.2307g of aluminum oxyhydroxide, 4.5357g of ethyl orthosilicate and 3.4746g of TMHD were added in sequence, and stirring was continued for 12 hours. The reactant was transferred to a stainless steel autoclave, heated to 210°C in a closed manner, and crystallized at a constant temperature under its own pressure for 96 hours, and then naturally cooled to room temperature. The precipitate was washed with deionized water several times until the filtrate was neutral, the product was dried in a drying oven at 100°C for 12 hours, and calcined in a tube furnace at 550°C for 6 hours to obtain a solid powder. The obtained product is analyzed by XRD diffraction to be pure SAPO-44 microporous molec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com