pvd degassing heating chamber

A gas heating and heating device technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of temperature superposition, uneven temperature, untimely cooling and heat dissipation, etc., to reduce temperature superposition, avoid Passive heat source, fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

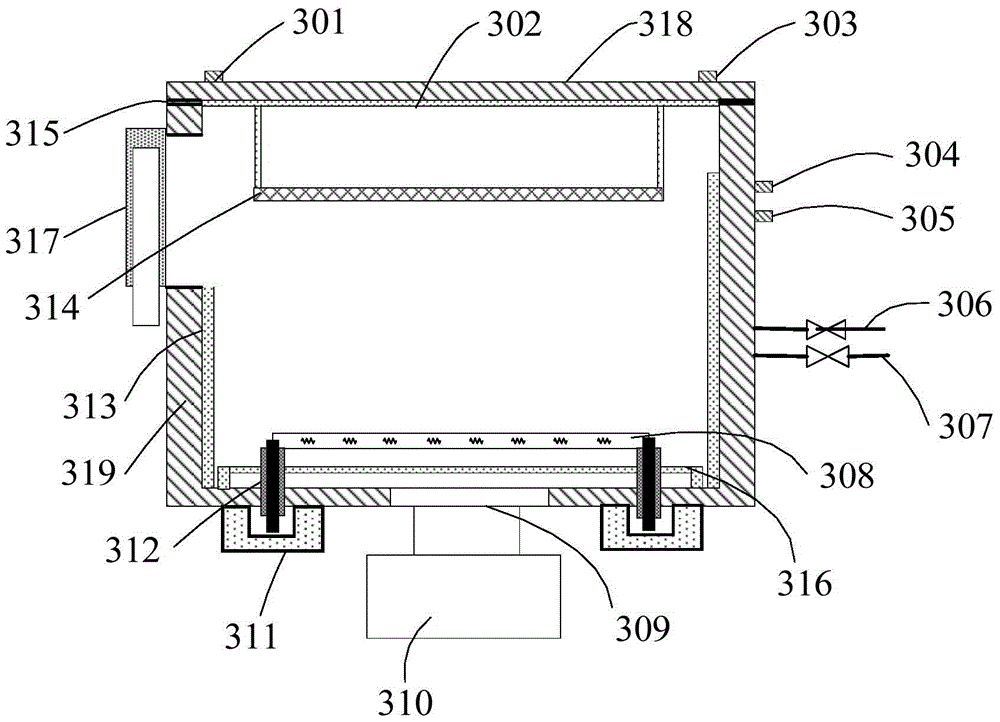

[0066] As a possible implementation manner, the supporting device includes a supporting frame 314 and a fixing rod 501 .

[0067] As a possible implementation manner, the first reflective plate 302 , the second reflective plate 313 and the third reflective plate 316 are all made of mirror material.

[0068] As a possible implementation manner, the first reflector 302 , the second reflector 313 and the third reflector 316 are all made of mirror stainless steel.

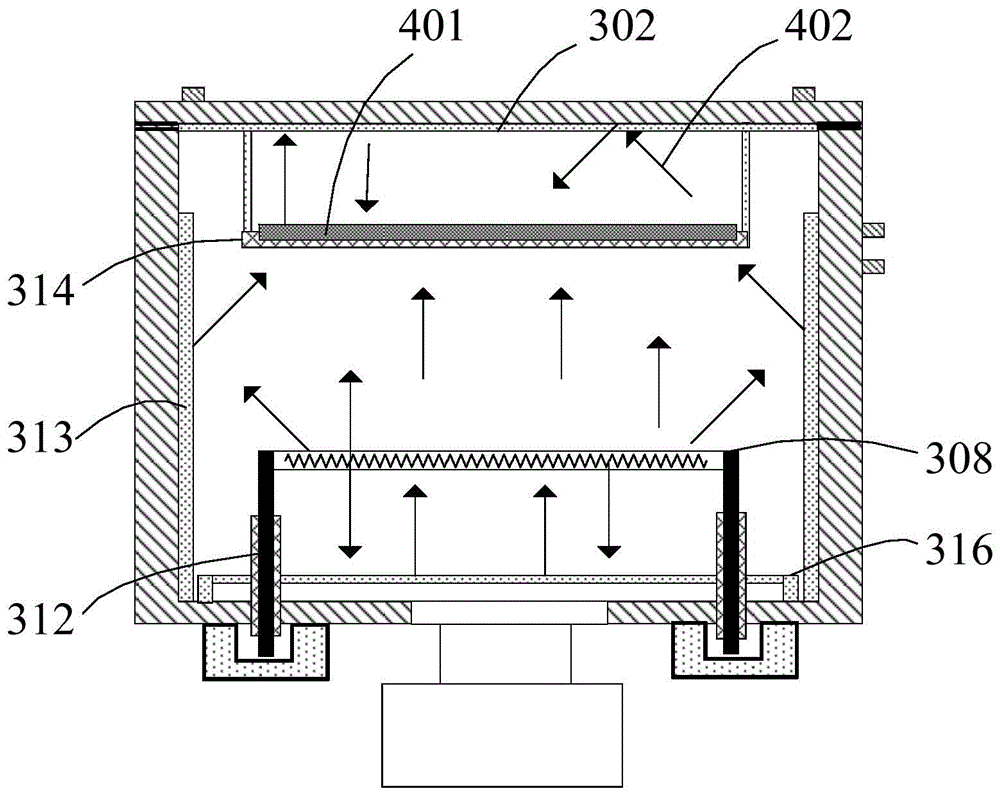

[0069] Please combine Figure 4 As shown, it is a partial top view schematic diagram of the use state of the supporting device of the PVD degassing heating chamber of the present invention. The fixing rod 501 is rod-shaped, one end of which is fixed on the first sealing cover 318, and the other end is equipped with a supporting frame 314. The sheet 401 is placed on the support frame 314 .

[0070] In this embodiment, in order to ensure firm fixing, the supporting device is provided with three fixing rods 501 . The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com