clipping filter

A filter and filter body technology, which is used in wellbore/well components, earthwork drilling, wellbore flushing, etc., can solve the problems of reducing the work intensity of derrick workers, not placing conventional filter elements, and increasing the work intensity of derrick workers. The effect of meeting the needs of offshore operations, reducing the labor intensity of workers, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

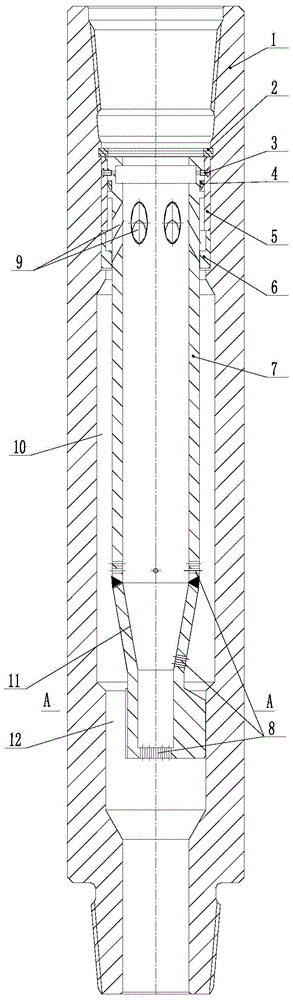

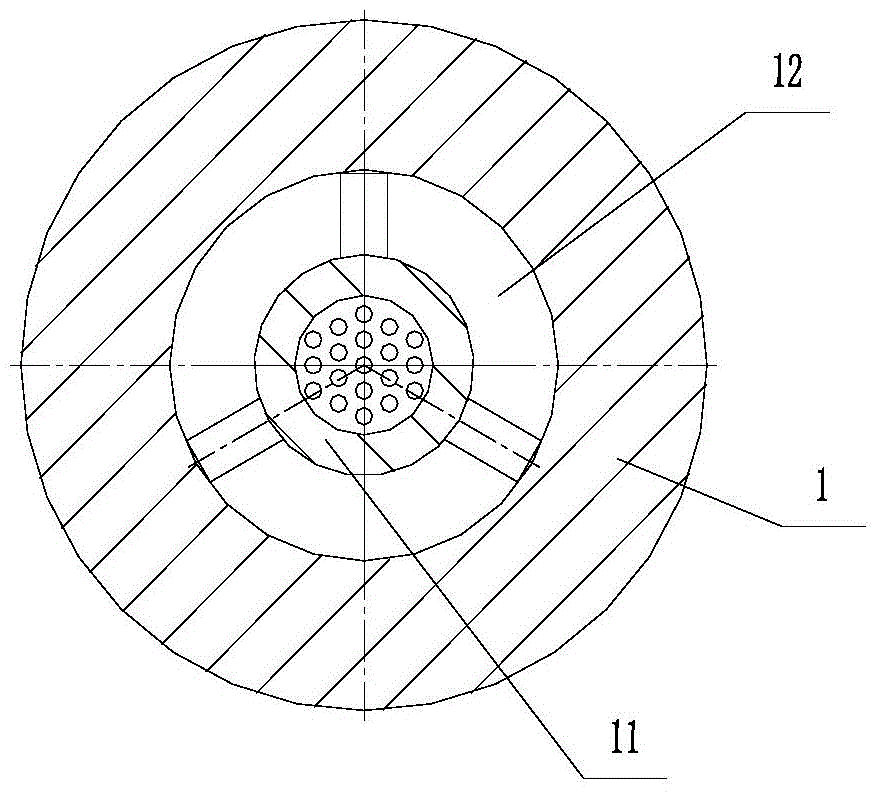

[0014] see figure 1 and figure 2 , a shear pin filter, including a cylinder 1 and a filter assembly installed inside it; the upper and lower ends of the cylinder 1 are provided with threads; the filter assembly includes a filter body 7, a centralizer 11, The hanging sleeve 5 and the limit sleeve 6 are fixedly connected with the centralizer 11 at the lower end of the filter body 7, and the centralizer 11 is slidably connected with the cylindrical body 1. Between the centralizer 11 and the filter An overflow channel 12 is formed between the bodies 1, and a filter hole 8 is provided on the centralizer 11 and the filter body 7; an annular space 10 is formed between the cylinder body 1 and the filter body 7, The upper end of the filter body 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com