Noise abatement device for draught fan and application method of noise abatement device

A technology of a muffler device and a fan, which is applied to the components of the pumping device for elastic fluids, mechanical equipment, machines/engines, etc. The effect is obvious, protect the environment, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

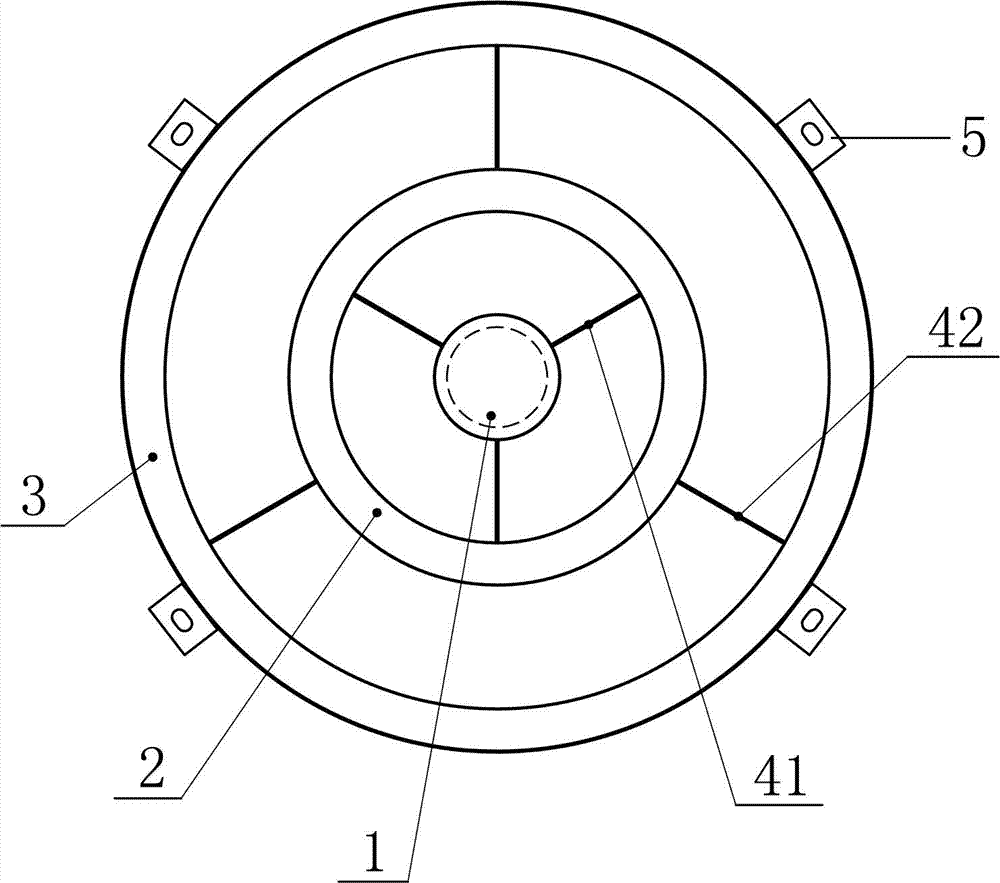

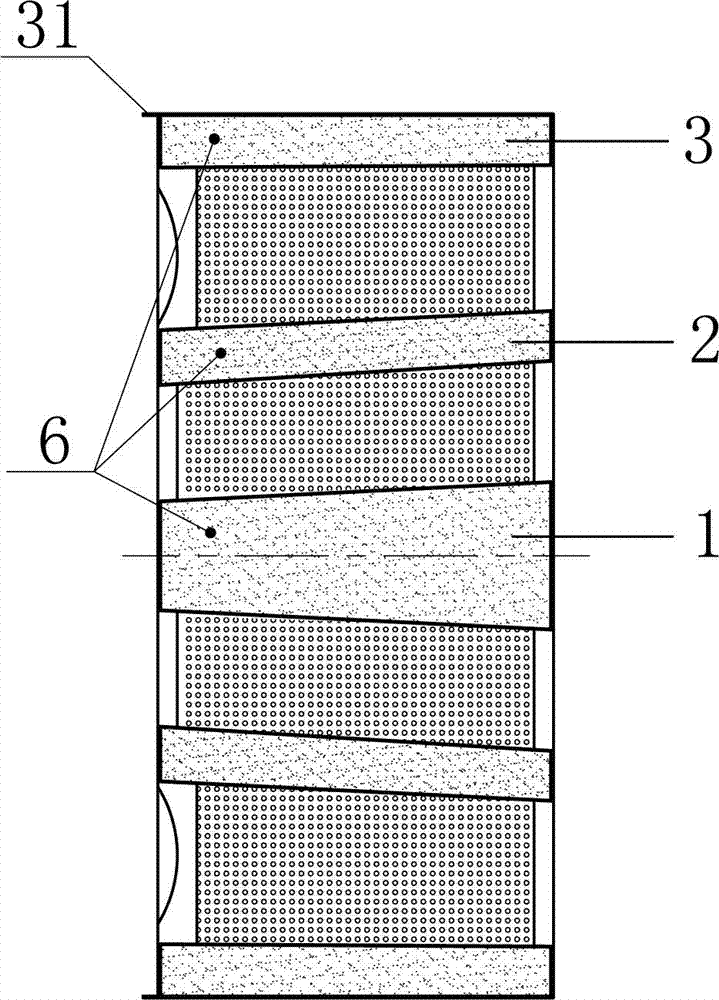

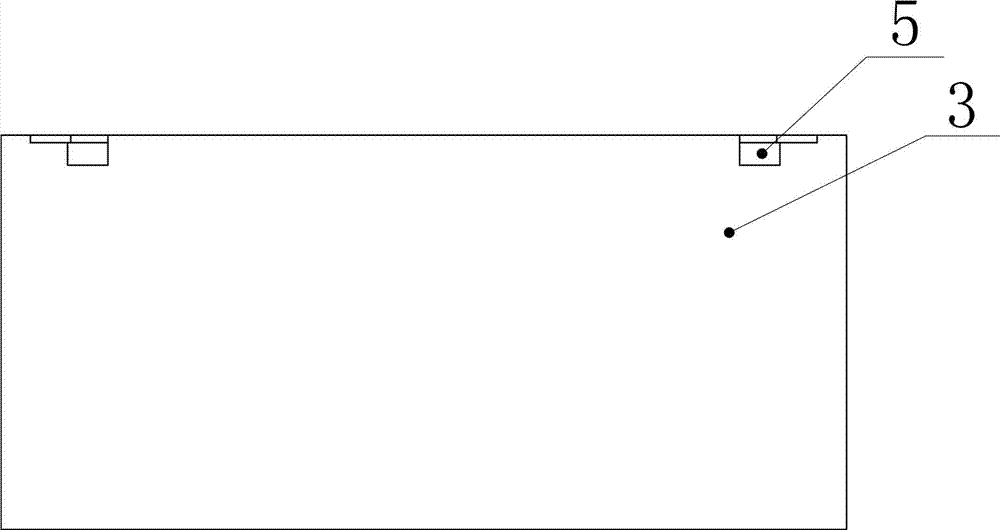

[0026] A noise reduction device for a fan, comprising a center column 1, a middle ring tube 2, an outer ring tube 3, an inner panel 41, an outer panel 42 and an ear plate 5, such as Figure 1 ~ Figure 4 As shown, the specific structure is:

[0027] The middle ring tube 2 is set outside the center column 1, the outer ring tube 3 is set outside the middle ring tube, and the central axes of the center column 1, the middle ring tube 2 and the outer ring tube 3 coincide with each other;

[0028] The outer wall of the center column 1 and the inner wall of the middle ring tube 2 are connected by three inner panels 41, and the inner panels 41 are evenly distributed along the outer wall of the center column 1, that is, the inner panels 41 are located at the center of the cross section of the center column 1. on the third point;

[0029] The outer side wall of the middle ring tube 2 and the inner side wall of the outer ring tube 3 are connected by three fast outer panels 42, and the ou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap