Fuel gas electromagnetic valve control circuit

A gas solenoid valve and control circuit technology, which is applied in the direction of battery circuit devices, circuit devices, valve details, etc., can solve the problems of control solenoid valve misoperation, high energy consumption of solenoid valve operation, safety hazards, etc., and reduce the working current Strength, good promotion and application value, and guaranteed normal working effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

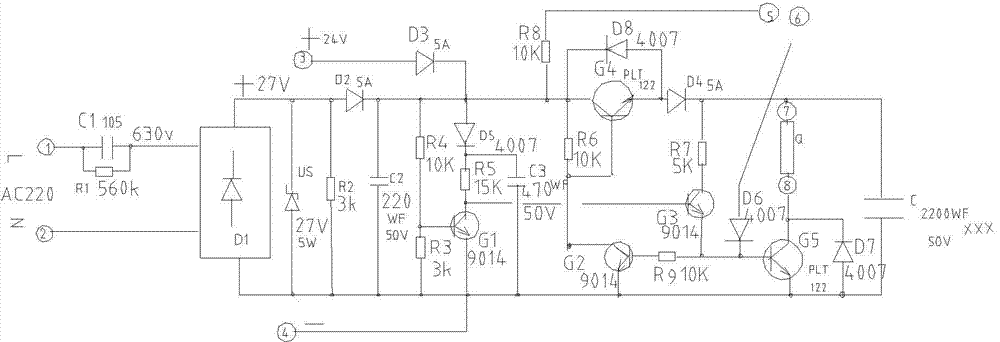

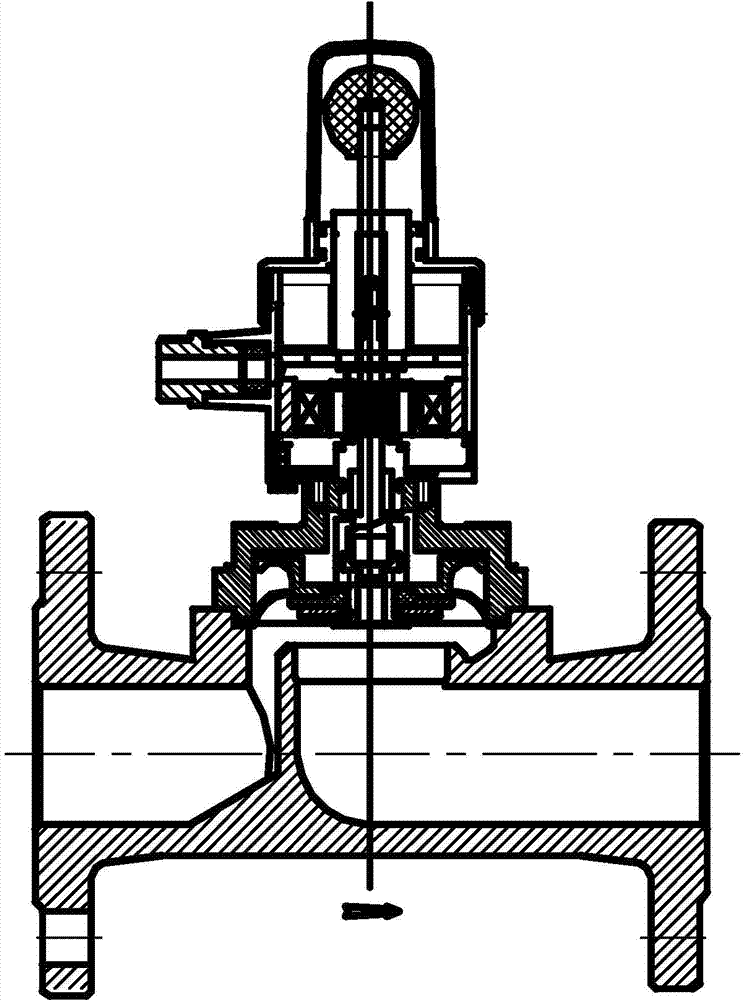

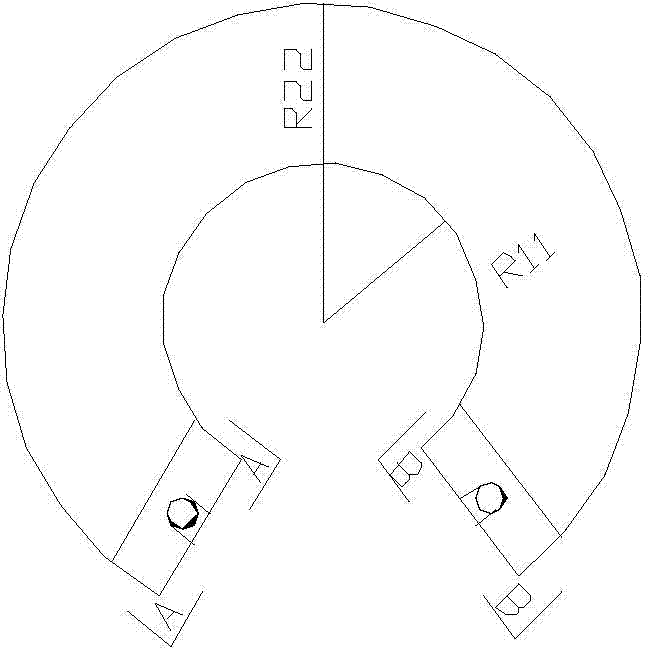

[0018] Such as figure 1 , 2 , 3, 4, 5, a gas solenoid valve control circuit, including: alternating current AC 200V, the first triode G1, the second triode G2, the third triode G3, the fourth triode G4 , the fifth triode G5; the first capacitor C1 and the capacitor C; the Schottky diode US, the first diode D1, the second diode D2, the third diode D3, the fourth diode D4, Fifth diode D5, sixth diode D6, seventh diode D7, eighth diode D8; first resistor R1, second resistor R2, third resistor R3, fourth resistor R4, fifth The resistor R5, the sixth resistor R6, and the seventh resistor R7, wherein, the AC 220V capacitor step-down full-wave rectification and voltage stabilization device composed of the first capacitor C1, the first diode D1, and the Schottky diode US, The alternating current AC220V passes through the first capacitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com