Dynamic measurement method of geometric parameters of overhead contact system

A technology for geometric parameter and dynamic measurement, applied in measurement devices, instruments, and optical devices, etc., can solve the problems of inability to obtain contact line state parameters, affecting the safety of passenger cars, and personnel fatigue, and improve detection accuracy, efficiency, and price. Inexpensive and accident-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

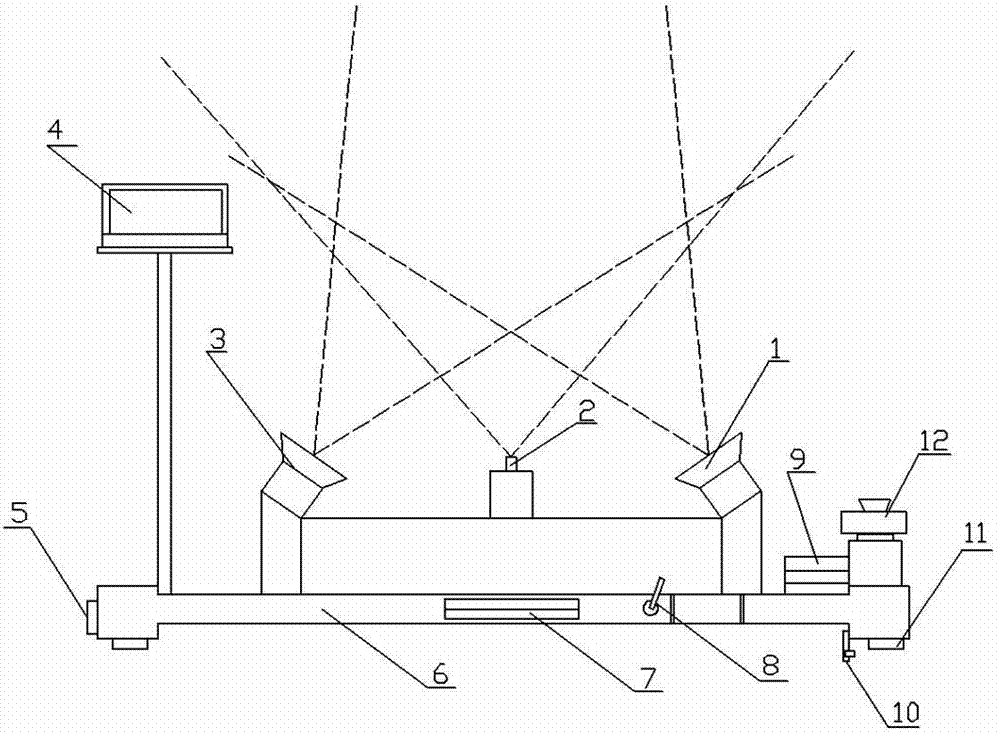

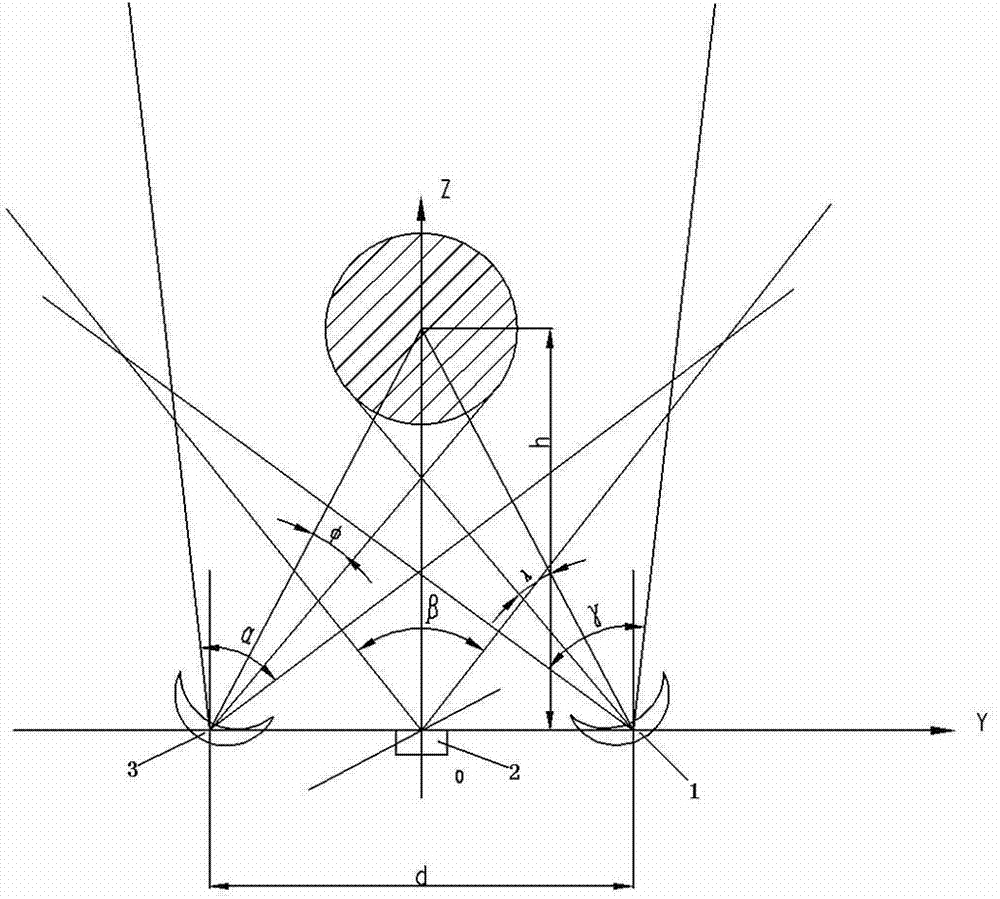

[0022] Example: such as figure 1 As shown, the method for dynamic measurement of catenary geometric parameters in this embodiment involves a mobile trolley. The car body 6 of the mobile trolley has wheels 11, the wheels 11 are erected on the rails and can move along the laying direction of the rails, above the rails is the catenary to be measured. The body of the mobile car is equipped with a right line camera 1 and a left line camera 3, and the array cameras are symmetrically distributed on both sides with the line laser 2 as the center of symmetry, and the shooting lines of the two cameras coincide with the laser band emitted by the laser. The beam emitting surface of the line laser 2 faces the catenary to be measured, and the irradiation surfaces of the two line array cameras are also aimed at the catenary.

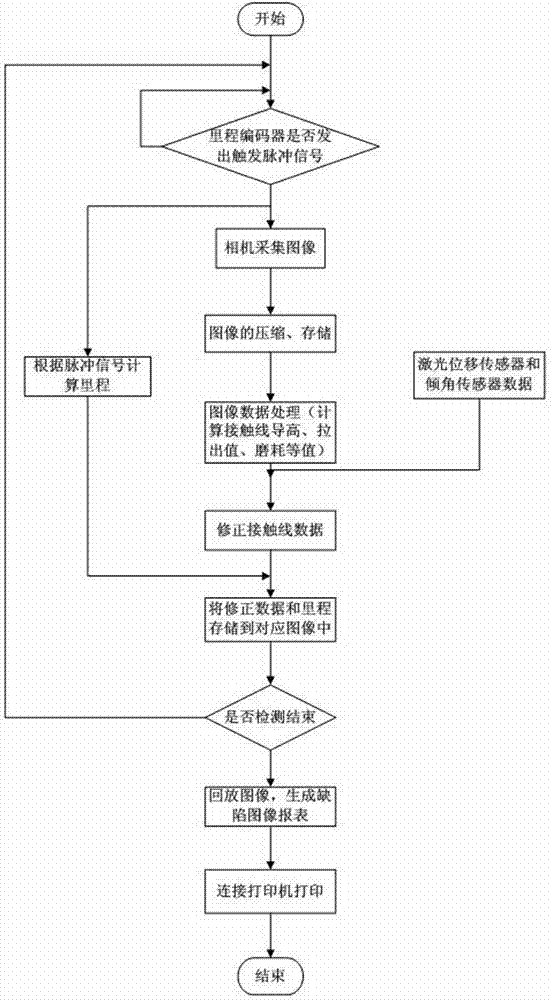

[0023] The mileage encoder 5 at the left wheel of the mobile trolley body 6 outputs pulse signals according to the travel distance of the wheels 10, and provides the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com