Online Duvel whole temperature interval cold loss measuring method

A technology of temperature range and ambient temperature, applied in measuring devices, measuring heat, cooling machines, etc., can solve the problems that radiation heat leakage and conduction heat leakage cannot be measured separately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] A specific embodiment of the present invention is described in detail below:

[0053] 1 Determine the specific conditions of the test

[0054] Make sure the ambient temperature of the test is 300K±1K and keep the ambient temperature within this range throughout the test

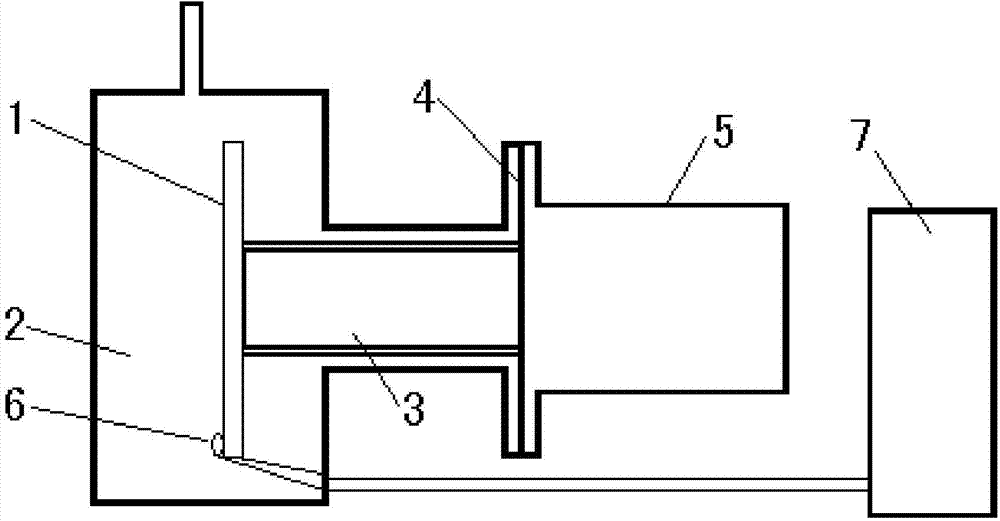

[0055] Determine the coupling state of the Dewar 2 and the refrigerator 5, insert the cold finger 3 of the refrigerator into the Dewar stem column and form a good thermal contact with the Dewar cold head 1, and fasten it at the flange 4.

[0056] 2. The refrigerator 5 is used to cool down the temperature of the Dewar cold head 1, and the temperature of the Dewar cold head 1 is lowered to below 130K.

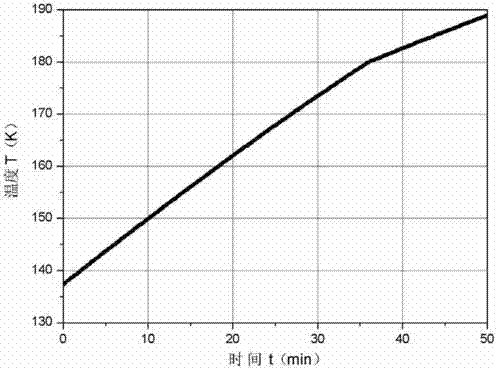

[0057] 3 Use the fluke data acquisition system 7 to automatically collect the temperature of the temperature measuring diode 6 installed on the Dewar cold head 1, and obtain the temperature change curve of the Dewar cold head, see figure 2 .

[0058] 4 Data processing

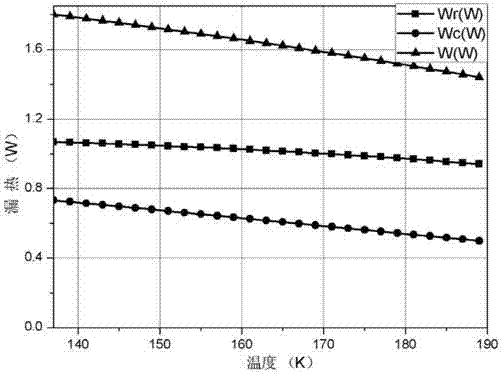

[0059] Perform polynomial fitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com