Morphological-control nano titanium dioxide doped with inorganic vanadate and palladium salt as well as preparation method and application of morphological-control nano titanium dioxide

A nano-titanium dioxide and titanium dioxide technology, applied in the nanometer field, can solve the problems of irritating the eyes, skin and respiratory system, and the price is too expensive, and achieve the effect of increasing the reactive point, improving the gas sensitivity and increasing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of the nano titanium dioxide of embodiment 1, vanadium, palladium co-doping, steps are as follows:

[0038] (1) Measure 0.6 mL of tetrabutyl titanate and add it dropwise to 25 mL of ethanol solution, and stir at room temperature for 20 min to obtain a sol;

[0039] (2) Weigh 8.62mg Na 3 VO 4 and 17.5mg Pd(NO 3 ) 2 2H 2 O was dissolved in 50 mL of twice distilled water, dropped into the above sol, and stirred at room temperature for 20 min;

[0040] (3) Place the sol mixture prepared in step (2) in a water bath at 30° C., heat-treat the sol, and slowly evaporate the solvent to obtain a gel;

[0041] (4) After grinding the gel prepared in step (3), calcining at 450° C. for 2 hours to obtain vanadium and palladium co-doped nano-titanium dioxide powder.

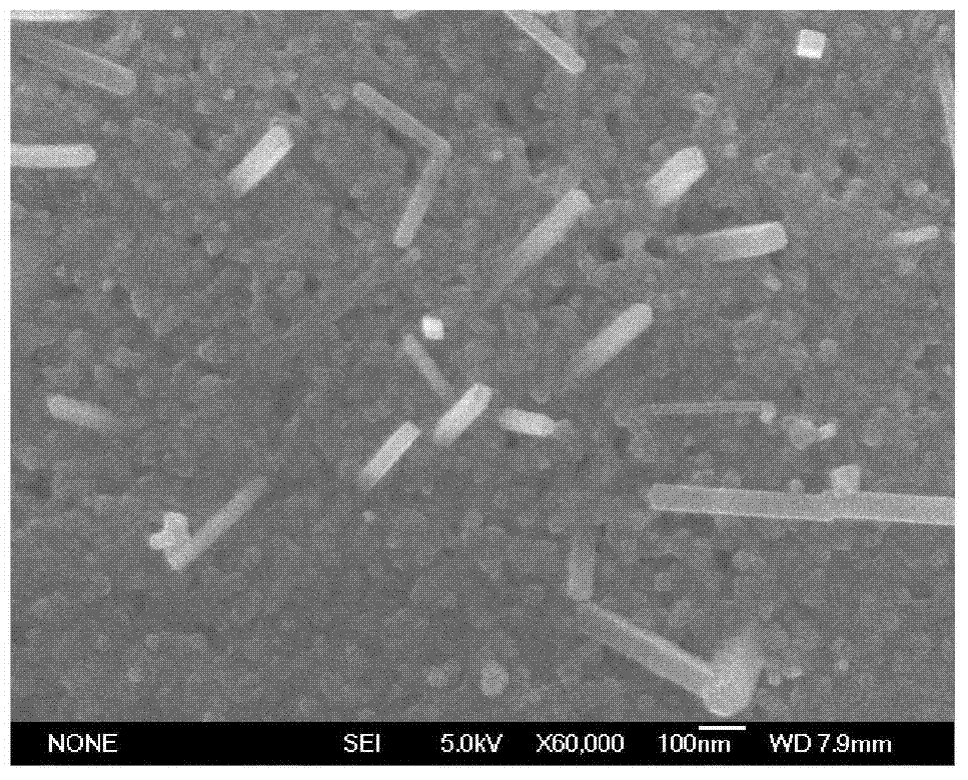

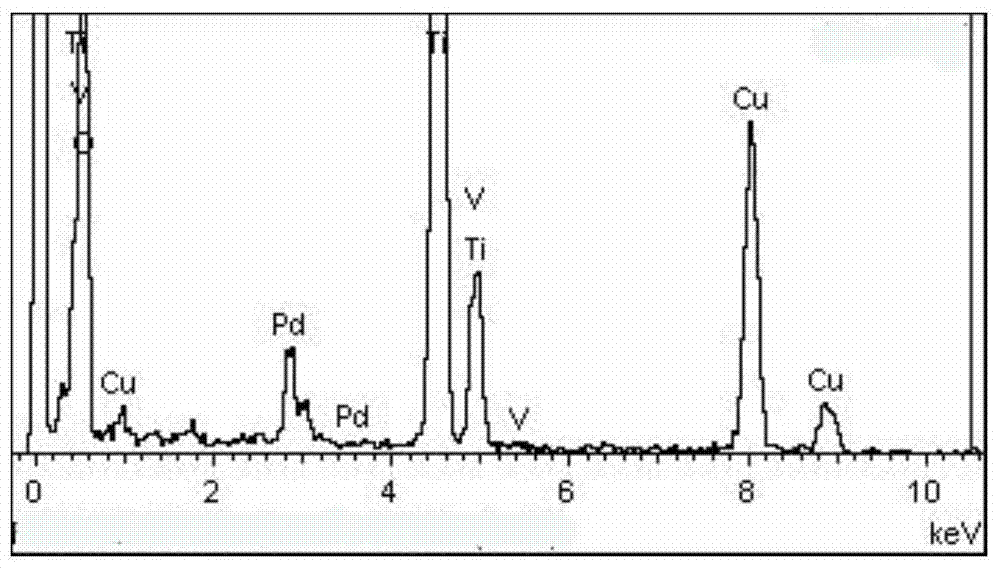

[0042] The prepared nano-titanium dioxide is anatase type, presenting two kinds of morphology at the same time. Nano-titanium dioxide particles have a particle size of ~25nm, and rod-shaped titanium ...

Embodiment 2

[0043] Embodiment 2, application of vanadium, palladium co-doped nano-titanium dioxide gas-sensing material

[0044] Take 5 mg of vanadium and palladium co-doped nano-titanium dioxide powder prepared in Example 1, grind it finely, add a small amount of terpineol to make a paste, apply it evenly on the alumina ceramic tube, and place it in a muffle furnace at 300 °C Internally sintered for 2 hours to make a tube core, and welded and packaged according to the conventional process of side-heated devices to obtain gas-sensitive sensor devices (such as Figure 4 shown). After 120 hours of electrical aging, the properties of the gas sensor were measured with a HW-30A gas sensor tester.

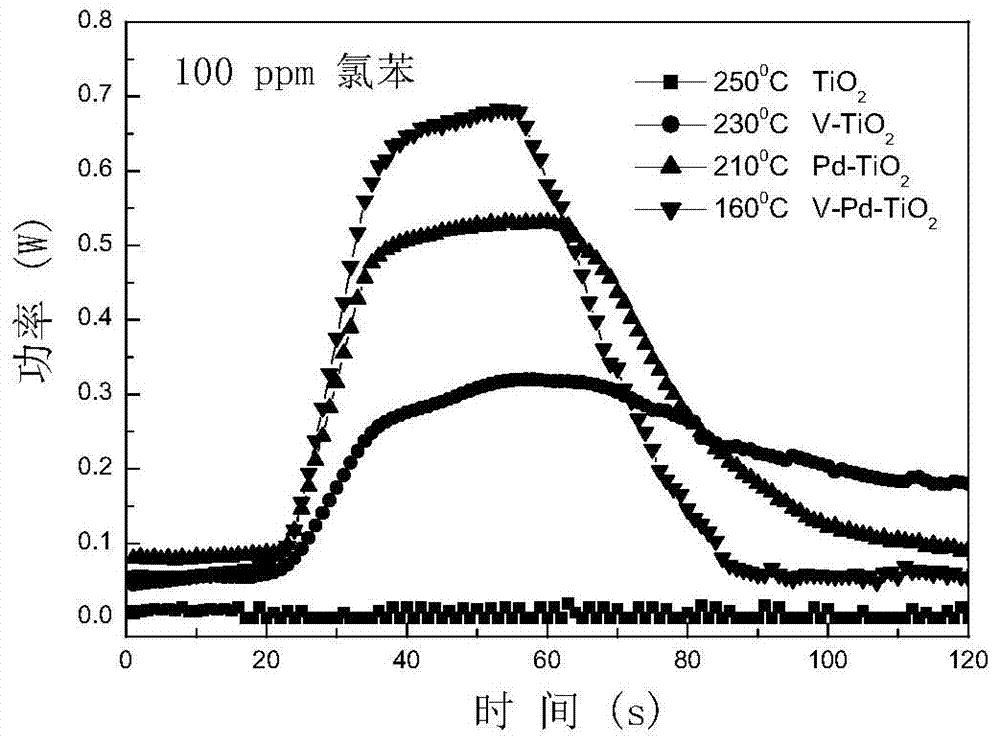

[0045] At an operating temperature of 160°C, the gas-sensing properties of 100ppm chlorobenzene were tested. From the response-recovery curve of the gas sensor to 100ppm chlorobenzene, such as image 3 As shown, it can be seen that the response and recovery time of chlorobenzene are 10s and 21s res...

Embodiment 3

[0070] The preparation of the nano-titanium dioxide of embodiment 3, vanadium, palladium co-doping, steps are as follows:

[0071] (1) Measure 0.6 mL of tetrabutyl titanate and add it dropwise to 25 mL of ethanol solution, and stir at room temperature for 25 min to obtain a sol;

[0072] (2) Weigh 10.34mg Na 3 VO 4 and 19.98mg Pd(NO 3 ) 2 2H 2 O was dissolved in 50 mL of twice distilled water, dropped into the above sol, and stirred at room temperature for 25 min;

[0073] (3) Place the sol mixture prepared in step (2) in a water bath at 35° C., heat-treat the sol, and slowly evaporate the solvent to obtain a gel;

[0074] (4) After grinding the gel prepared in step (3), calcining at 480° C. for 1.5 h to obtain vanadium and palladium co-doped nano titanium dioxide powder.

[0075] The prepared nano-titanium dioxide is anatase type, showing two shapes at the same time, nano-titanium dioxide particles with a particle size of about 30nm, and rod-shaped titanium dioxide with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com