Electronic device

A technology for electronic components and components, which is applied to printed circuit components, electrical components, components of fixed capacitors, etc., and can solve problems such as sound and sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

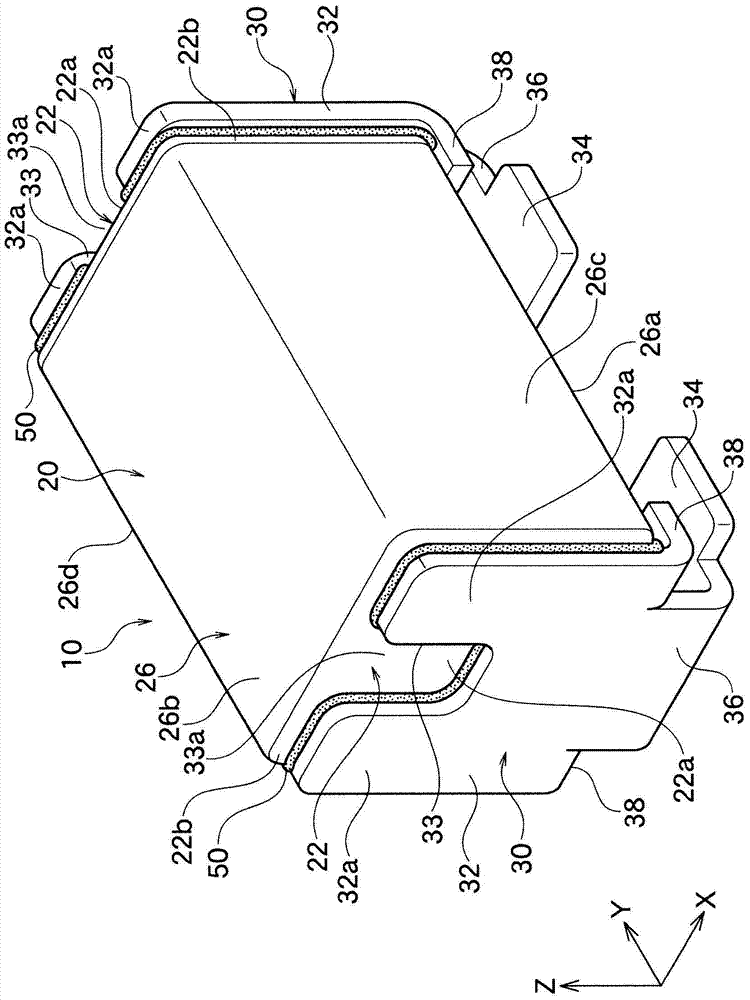

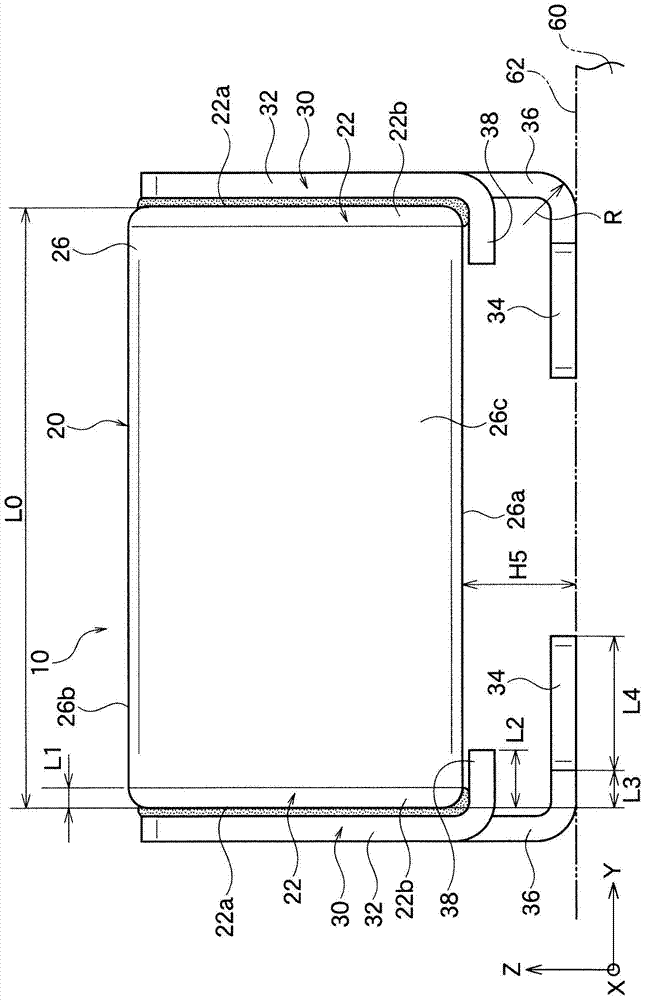

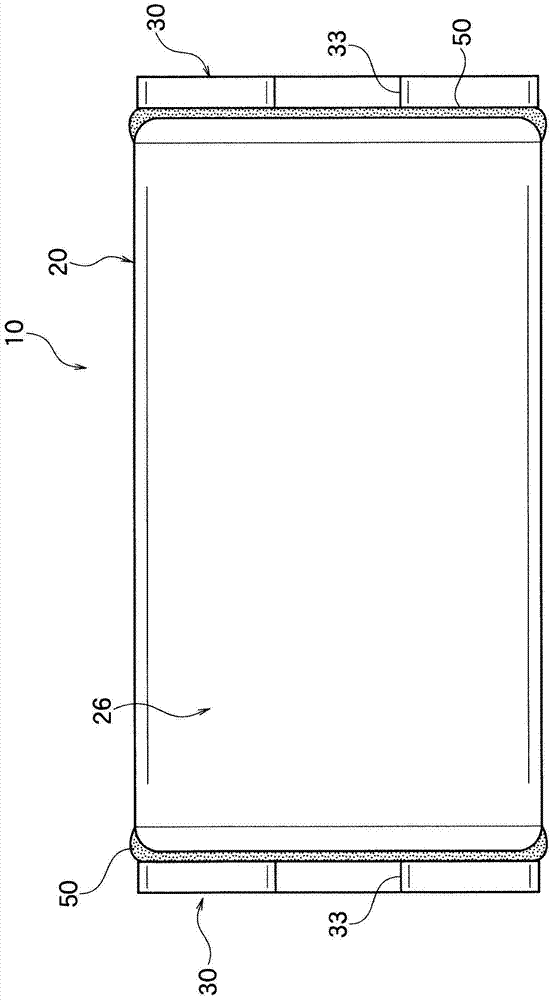

[0062] figure 1 It is a schematic perspective view showing a ceramic capacitor 10 as an electronic component according to the first embodiment of the present invention. The ceramic capacitor 10 has a chip capacitor 20 as a chip component, and a pair of metal terminals (external terminals) 30 respectively attached to both end faces of the chip capacitor 20 in the Y-axis direction.

[0063] In addition, in the description of each embodiment, the ceramic capacitor in which the pair of metal terminals 30 is mounted on the chip capacitor 20 has been described as an example, but the ceramic electronic component of the present invention is not limited to this, and may be other than Electronic components having metal terminals 30 are mounted on chip components other than capacitors.

[0064] The chip capacitor 20 has a capacitor body 26 and a pair of terminal electrodes 22 respectively formed on both end faces of the capacitor body 26 in the Y-axis direction. The capacitor element b...

no. 2 Embodiment approach

[0100] Figure 12 It is a perspective view of a ceramic capacitor 10A according to a second embodiment of the present invention. The ceramic capacitor 10A according to this embodiment is not Figure 1 to Figure 11 The ceramic capacitor 10 according to the first embodiment shown has the same structure as those described below, and exhibits the same functions and effects. Therefore, the common parts are given the same reference numerals and the common parts are omitted. instruction of.

[0101] Such as Figure 12 As shown, in this embodiment, the terminal electrode connecting portion 32A of the terminal electrode 30A is not formed. figure 1 Groove 33 is shown. Ceramic capacitor 10A of this embodiment is not formed figure 1 Other than the grooves 33 shown, the same functions and effects as those of the ceramic capacitor 10 of the first embodiment are exerted.

no. 3 Embodiment approach

[0103] Figure 13 It is a perspective view of a ceramic capacitor 10B according to the third embodiment of the present invention. The ceramic capacitor 10B according to this embodiment except Figure 1 to Figure 11 The ceramic capacitor 10 according to the first embodiment shown has the same structure as those described below, and exhibits the same functions and effects. Therefore, the common parts are given the same reference numerals and the common parts are omitted. instruction of.

[0104] Such as Figure 13 As shown, in this embodiment, the length in the Y-axis direction of the side electrode portion 22b of the terminal electrode 22 formed on the end surface of the element body 26 of the chip capacitor 20B is longer than that of the side electrode portion 22b of the terminal electrode 22 in the first embodiment. The length in the Y-axis direction is longer. The ceramic capacitor 10B of this embodiment has the same function as that of the first embodiment except that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com