High-strength stainless steel sheet having excellent fatigue characteristics, and method for manufacturing same

A technology of stainless steel plate and manufacturing method, applied in the field of steel plate, can solve the problem of inability to stably reduce TiN-based inclusions and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

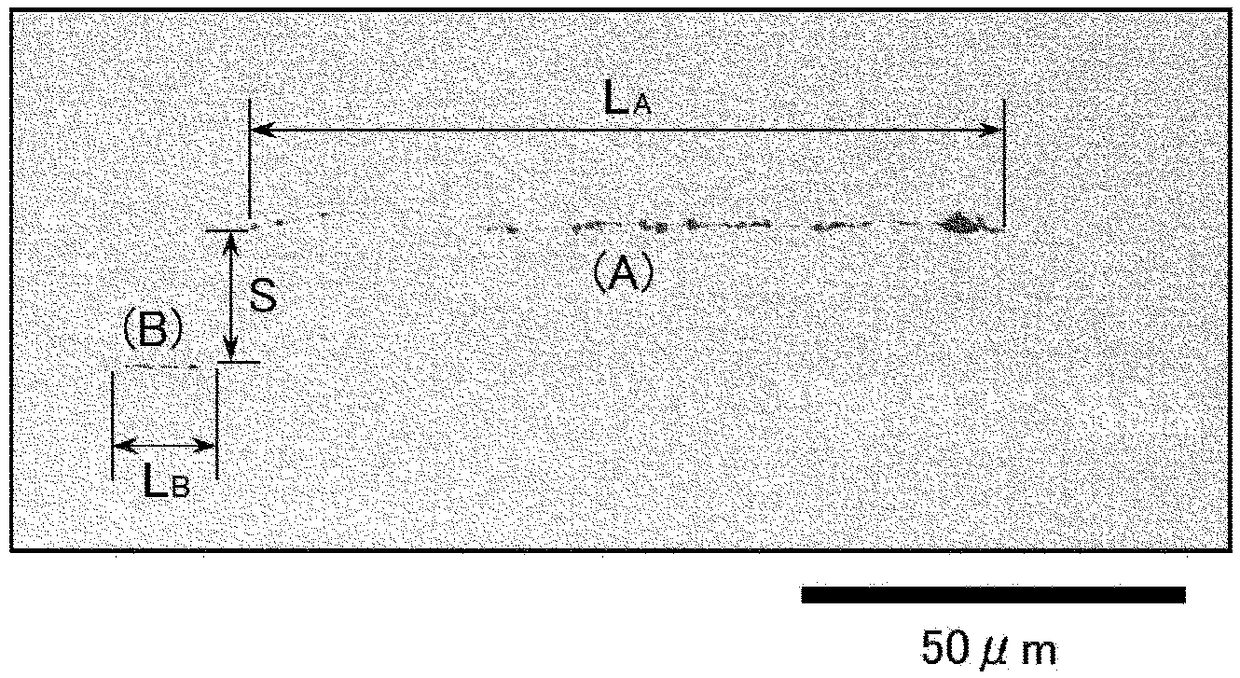

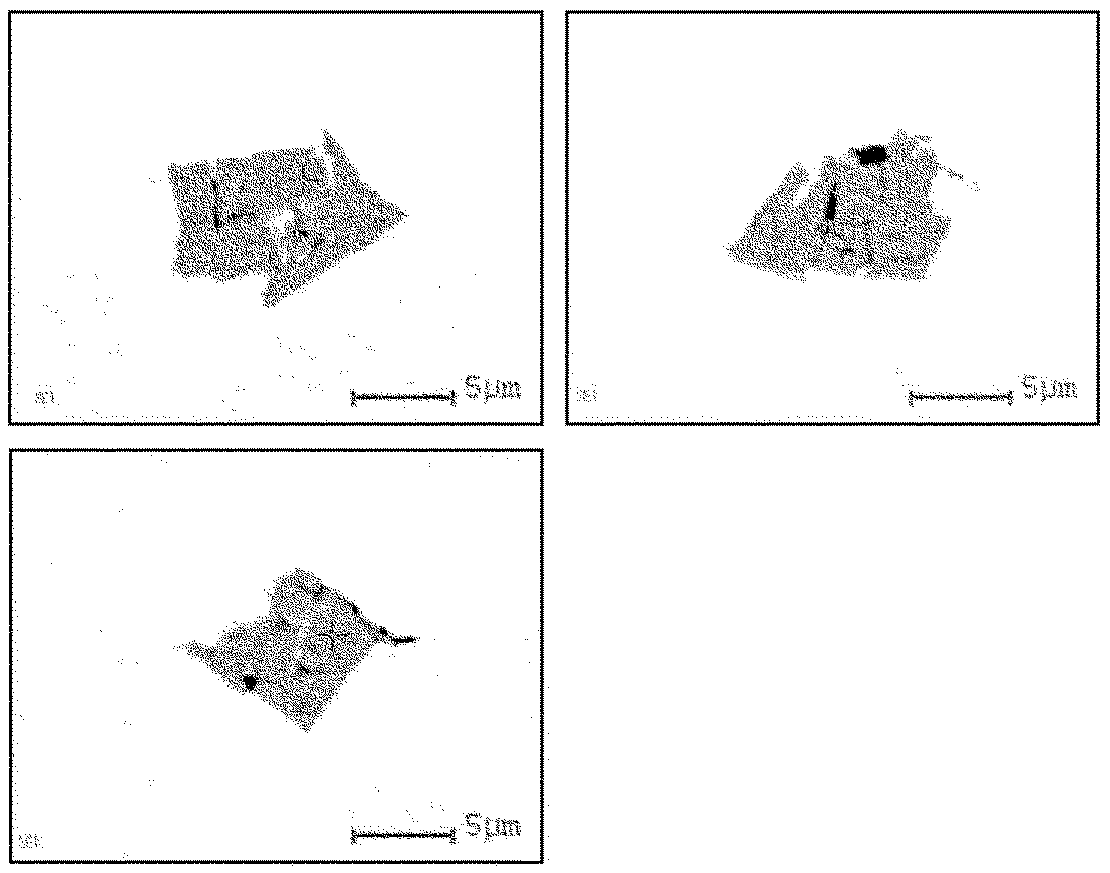

Image

Examples

Embodiment

[0096] The steels shown in Table 1 were melted by the VOD method. Both use VOD equipment to complete the final decarburization process of blowing oxygen into Cr-containing molten iron, and obtain molten steel with a C content of 0.10% or less of slag containing Cr oxides on the molten surface. The C content in this stage was approximately equal to the final C content shown in Table 1.

[0097] [Table 1]

[0098] Table 1

[0099]

[0100] In the final decarburization using a VOD facility, a ladle (pot) was used as a container for molten steel, and the same ladle was used until the process before casting. For this ladle, in the conventional examples of No. 1 and 2, as the fore charge, the fore charge used for smelting Ti-containing stainless steel is used, and in the conventional examples of No. 3 and 4, as the fore charge , the fore charge used in the smelting of stainless steel without adding Ti was used, and in the example of the present invention No. .

[0101] Fe-Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com