Micro blind hole manufacturing method for flexible packaging substrate

A flexible packaging and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as surface copper and black hole layer faults, difficult cleaning of carbon powder, difficulty of hole filling and electroplating, etc., to achieve easy fill effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

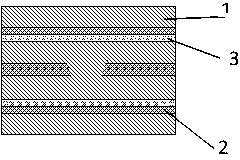

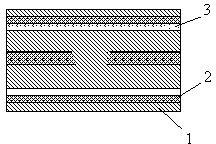

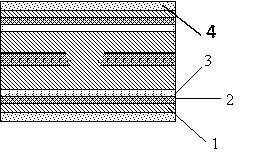

[0026] In the figure: copper foil layer 1, polyimide layer 2, adhesive layer 3, dry film 4, carbon powder layer 5.

[0027] as attached figure 1 As shown, the present invention uses a 12um thick buried blind hole four-layer board as the base material, and the middle connecting layer can be a polyimide layer 2 of 25 or 50um, a polyester layer or a polyethylene naphthalate layer, The connection layer is covered with a copper foil layer 1, and the connection layer is covered on the base material through an adhesive layer 3;

[0028] as attached figure 2 As shown, the 12um-thick buried blind hole four-layer board substrate is subjected to copper reduction treatment, so that the surface copper thickness is reduced from 12um to about 4um;

[0029] as attached image 3 As shown, a dry film 4 is attached to the surface of the thinned four-layer substrate with blind holes for p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com