How to Replace Butterfly Valve by Vacuumizing Transformer with Oil

A transformer and vacuuming technology, which is applied in the manufacture of inductors/transformers/magnets, switchgear, electrical components, etc., can solve the problems of economic losses, troublesome preparations, and long power outages in industrial enterprises of users, so as to reduce economic losses and reduce Power outage time, time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

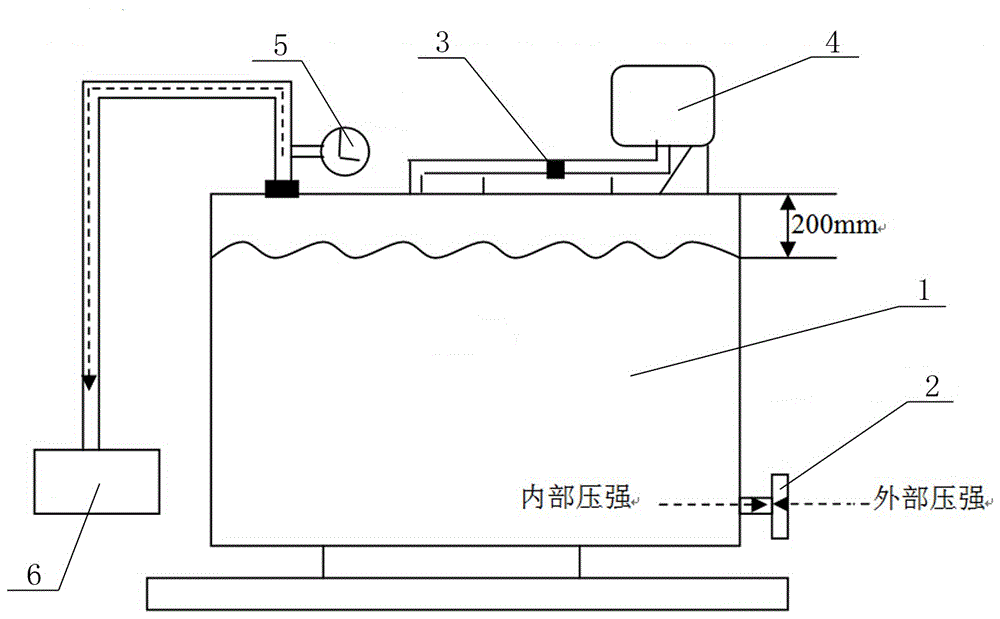

[0042] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0043] A method for replacing a butterfly valve by vacuuming a transformer with oil, such as figure 1 shown, including the following steps:

[0044] (1) Close the normal butterfly valve 3 between the oil pillow 4 and the transformer body, close all the normal butterfly valves between the transformer body and the radiator, and close the normal butterfly valve between the clean oil tank and the transformer body.

[0045] (2) Part of the main body oil 1 in the transformer is released from the oil drain port, so that the oil level drops below the oil pillow, and further drops by 200mm to make necessary space for vacuuming and pressure reduction.

[0046] (3) Remove the thermometer at the thermometer port and vacuumize the connecting tube of the thermometer.

[0047] (4) Connect the vacuum pump 6 to evacuate.

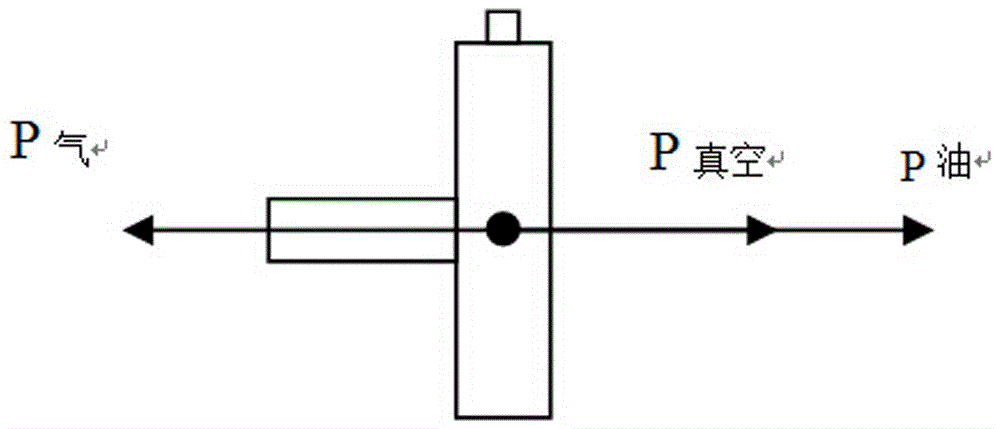

[0048] (5) Pay attention to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com