Single phase shaded pole motor with heat sink

A single-phase cover and radiator technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of poor heat dissipation effect of shaded pole motors, difficulty in guaranteeing working reliability and normal working life, and achieve normal working life , Reduce the workload of daily maintenance and inhibit the accumulation of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

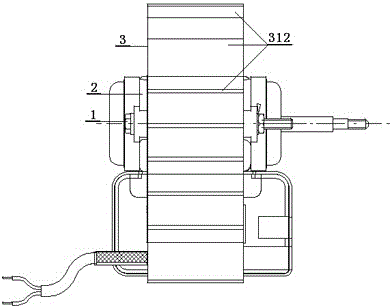

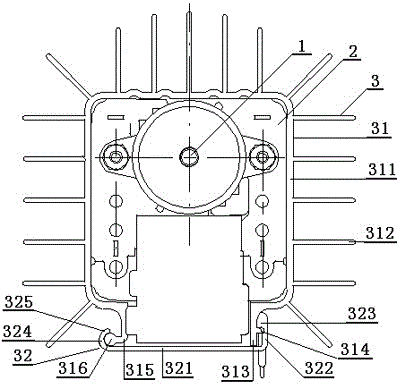

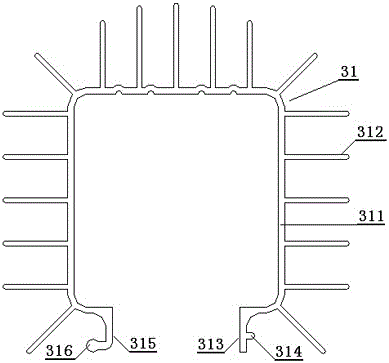

[0018] exist figure 1 , figure 2 , image 3 with Figure 4 Among them, the main body of the single-phase shaded pole motor with radiator of the present invention is composed of a rotor 1 and a stator 2, and is characterized in that a metal radiator 3 with good heat dissipation function is fastened on the periphery of the stator 2, and the metal radiator 3 The main body includes a heat dissipation member 31 composed of a bent base body 311 and a number of protruding radiating fins 312 fixedly arranged on the outer surface of the bent base body 311, and the heat dissipation member 31 is fixedly positioned on the single-phase shaded pole motor The limit retaining member 32 on the outer surface of the stator 2, wherein: the shape and size of the bent base 311 is consistent with the shape and size of the outer surface of the stator 2 of the singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com