Transmissions for Motor Vehicles

A technology of transmission and motor vehicle, applied in the direction of vehicle gearbox, transmission device, mechanical equipment, etc., can solve the problems of impossible transmission and complex transmission structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

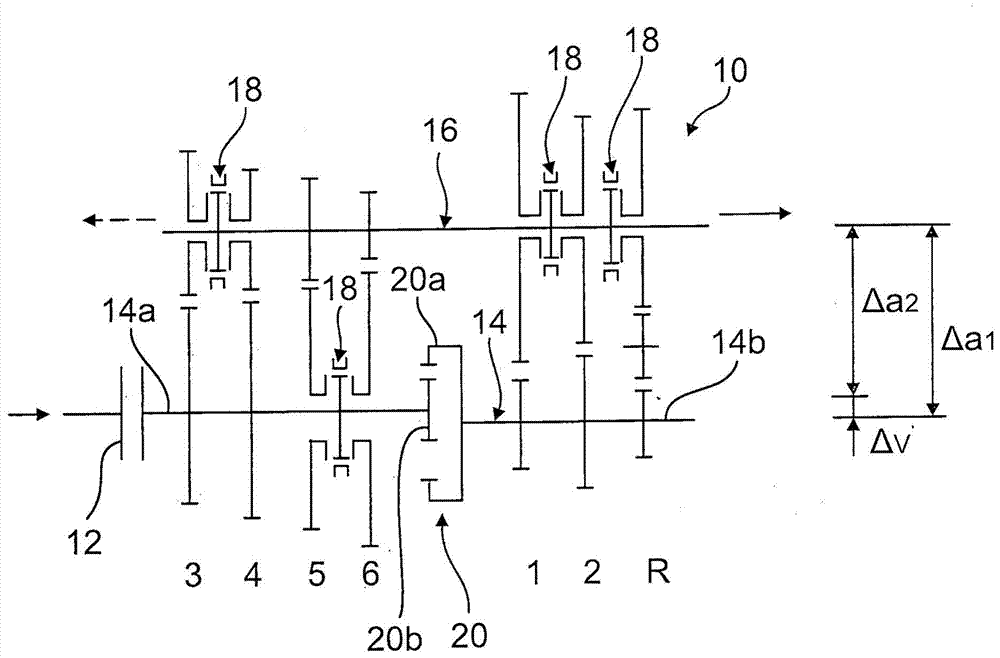

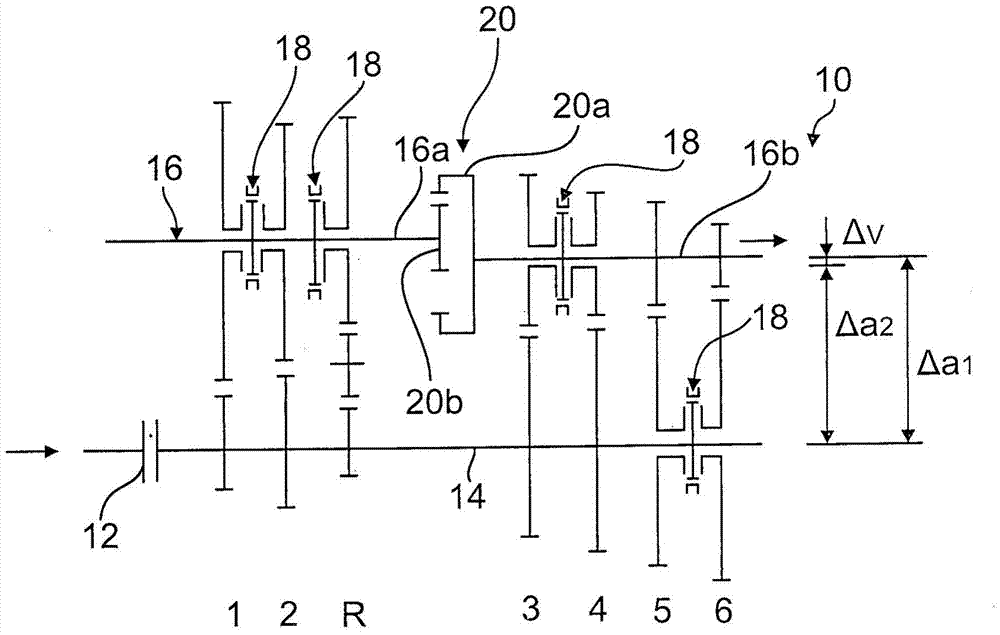

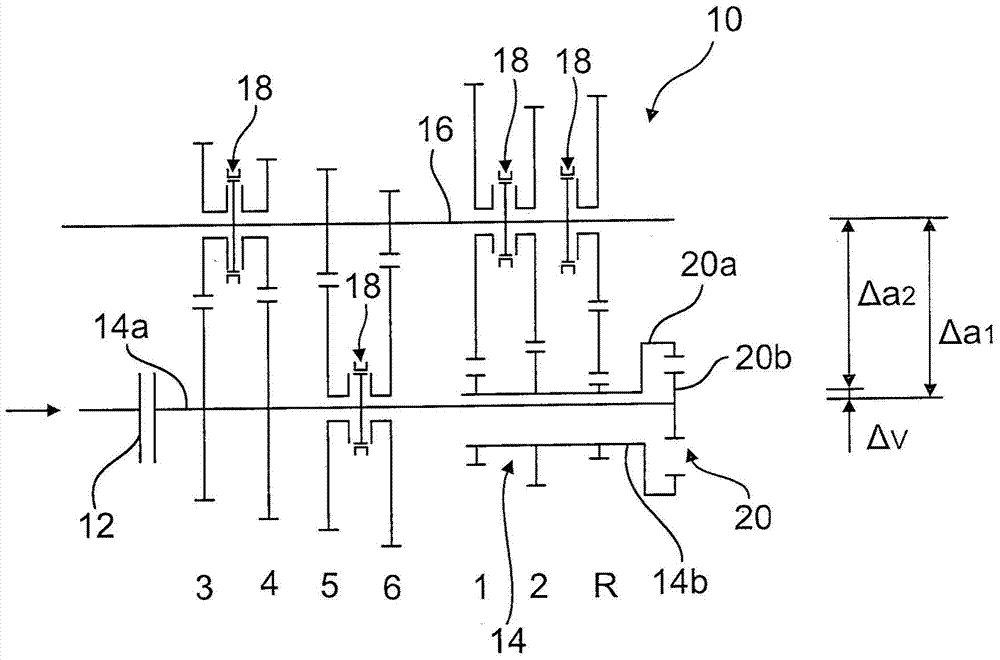

[0023] in figure 1 A transmission or shift transmission 10 for a motor vehicle is shown in the form of a block diagram without a transmission housing, which has an input shaft 14 and an output shaft 16 that can be connected to a driving device (not shown) via a disconnect clutch 12.

[0024] Arranged between the shafts 14 and 16 are gears of a gear set that mesh with each other. The gear set is used for six forward gears 1 to 6 and one reverse gear R. The floating gears of the gear sets 1 to 6 and the reverse gear R can be switched in a known manner by the synchronizing coupling device 18 that is only shown schematically, and can be connected to the corresponding fixed gears on the other shafts 14, 16 respectively. connection.

[0025] The two-piece input shaft 14 of the transmission 10 is engaged with each other through a ring gear stage 20, which has a ring gear 20a with a larger diameter and internal teeth and a cylindrical gear 20b meshing with the ring gear, wherein the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com