Preparation method for pearl buffalo milk jelly

A technology for buffalo milk and pearls, which is applied in the directions of dairy products, milk preparations, and applications, can solve the problems of complicated and complicated preparation methods, difficult industrialized production, and high production costs, and achieves fine tissue state of dairy products, low production costs, and high production costs. The effect of the simplicity of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

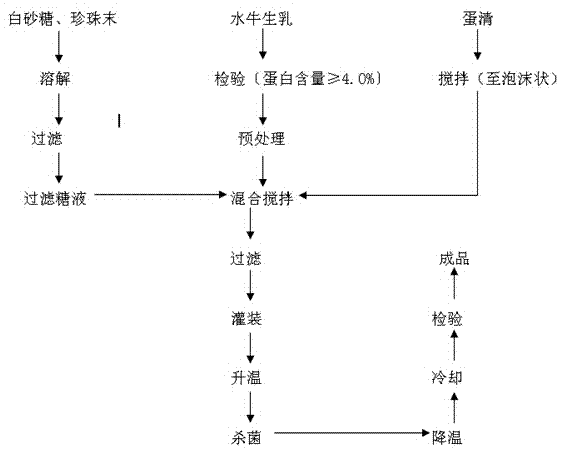

Image

Examples

Embodiment 1

[0020] The preparation method of this embodiment comprises the following steps:

[0021] a) Preparation of sugar solution: take 150 g of pearl powder and 6 kg of white granulated sugar, the particle size of pearl powder is 40-50 nanometers, heat and dissolve after mixing the two, and filter after dissolving to obtain filtered sugar solution;

[0022] b) Pretreatment of buffalo raw milk: take 88 kg of buffalo raw milk, the protein content of which is 3.8%, and then carry out standardized pretreatment at a temperature lower than 35°C to obtain pretreated buffalo raw milk;

[0023] c) Mixing: Take 5 kg of egg white and stir until foamy, mix and stir with the filtered sugar solution obtained in step a) and the pretreated buffalo raw milk obtained in step b), to make it reach a homogeneous state, then filter and mix Filling to obtain raw material liquid;

[0024] d) Sterilization and cooling: heat the raw material solution obtained in step c) to 95° C. within 20 minutes, maintain ...

Embodiment 2

[0027] a) Preparation of sugar liquid: take 150 g of pearl powder and 6 kg of white granulated sugar, the particle size of pearl powder is 45-50 nanometers, heat and dissolve after the two are mixed, and filter after dissolving to obtain filtered sugar liquid;

[0028] b) Pretreatment of buffalo raw milk: take 89 kg of buffalo raw milk, the protein content of which is 4.0%, and perform standardized pretreatment at a temperature lower than 35°C to obtain pretreated buffalo raw milk;

[0029] c) Mixing: Take 5 kg of egg white and stir until foamy, mix and stir with the filtered sugar solution obtained in step a) and the pretreated buffalo raw milk obtained in step b), to make it reach a homogeneous state, then filter and mix Filling to obtain raw material liquid;

[0030] d) Sterilization and cooling: heat the raw material solution obtained in step c) to 95° C. within 20 minutes, maintain a constant temperature of 95° C. for 20 minutes to sterilize, and then cool down naturally ...

Embodiment 3

[0033] a) Preparation of sugar solution: take 150 g of pearl powder and 6 kg of white granulated sugar, the particle size of pearl powder is 70-75 nanometers, heat and dissolve after mixing the two, and filter after dissolving to obtain filtered sugar solution;

[0034] b) Pretreatment of buffalo raw milk: take 90kg of buffalo raw milk, the protein content of which is 3.8%, and perform standardized pretreatment at a temperature lower than 35°C to obtain pretreated buffalo raw milk;

[0035] c) Mixing: Take 5 kg of egg white and stir until foamy, mix and stir with the filtered sugar solution obtained in step a) and the pretreated buffalo raw milk obtained in step b), to make it reach a homogeneous state, then filter and mix Filling to obtain raw material liquid;

[0036] d) Sterilization and cooling: Heating the raw material liquid obtained in step c) to 95° C. within 20 minutes, maintaining a constant temperature of 95° C. for 27 minutes to sterilize, and then cooling down nat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com