Medical sterile-isolation protection sleeve

A technology of isolation protection and protective cover, which is applied in the field of medical devices, can solve the problems of high production cost, easy discount, discount and protrusion of plastic protective cover, etc., and achieve the effect of reducing packaging requirements, facilitating connection and matching, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

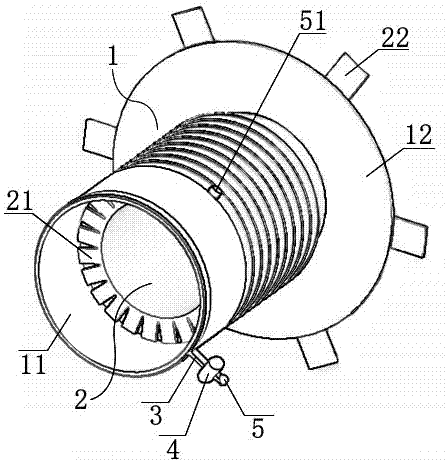

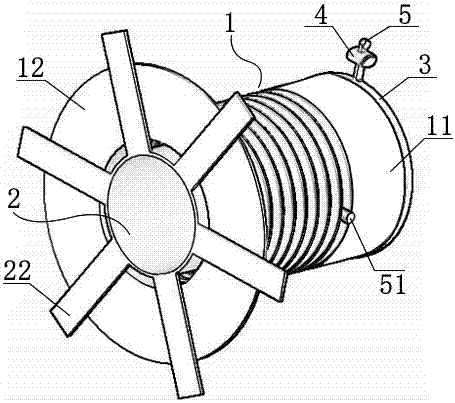

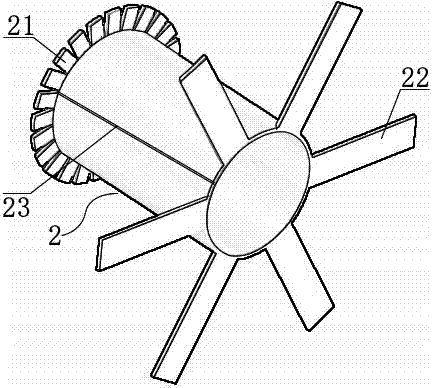

[0037] Such as Figure 1 to Figure 7 As shown, a medical sterile isolation protective cover includes a protective cover body 1, and the protective cover body 1 has an inner opening and an outer opening, wherein the end of the protective cover body 1 in contact with the aseptic area of the operation is the inner opening, which is connected with the equipment The end of the connection near the polluted area is the outer port. As an improvement of the present invention, the invention also includes a support sleeve 2 nested with the protective sleeve body 1, the diameter of the support sleeve 2 coincides with the inner diameter of the protective sleeve body 1, and the support sleeve 2 is installed on the protective sleeve body 1 Inside, the support sleeve 2 can move relative to the protective sleeve body 1 when being pulled. The support sleeve 2 has a certain hardness and thickness. 1 When folded in a corrugated manner, the support sleeve 2 installed in the pre-folded protectiv...

Embodiment 2

[0045] Such as Figure 8 As shown, it is the front view of the support sleeve described in the second preferred embodiment of the present invention. The other structures of this embodiment 2 are the same as those of the embodiment 1. The difference is that in this embodiment 2, the second bracket of the support sleeve 2 22 is provided with an extended handle 6, through which the support sheath 2 and the protective sheath body 1 can be pulled conveniently.

Embodiment 3

[0047] Such as Figure 9 As shown, it is the front view of the supporting sleeve described in the third preferred embodiment of the present invention. The other structures of this embodiment 3 are the same as those of Embodiment 1. The difference is that in this embodiment 3, the diameter of the supporting sleeve 2 is the same as The outer diameter of the protective sheath body 1 matches, so that the support sheath 2 can be movably placed outside the outer surface of the protective sheath body 1, and as an adaptive change, the frame pieces of the first bracket 21 are turned inward and aligned with the protective sheath body 1. The outer wall of the inner opening of the protective cover body 1 is matched, that is, the frames of the first bracket 21 and the second bracket 22 are all radially inward, and the frames are folded and sleeved on the outer wall of the protective cover body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com